dfma of sheet metal parts In this tutorial, we follow the steps used to create a turret press and a compound die analysis for the part modeled in the sample file sheet metal stamped part.dfmx included with your installa . $36.41

0 · sheet metal dfma tricks

1 · sheet metal dfma magic

2 · sheet metal dfma distance

3 · dfma hole thickness chart

4 · dfma for sheet metal

5 · dfm sheet metal

8 Pack White Storage Bins with Lids Stackable Storage Container for Organizing, Storage Boxes with Handle for Shelves, Cube Storage Bin for Craft, Snacks, 9.85x6.9x5.7 inch

DFMA focuses on simplifying designs and reducing the parts counts. It suggests using standardizing parts so they can be reused over and over in different applications. DFMA also provides.DFMPro for Sheet metal provides sheet metal design guidelines and DFM best practices to produce better quality designs at lower manufacturing costs.

In this tutorial, we follow the steps used to create a turret press and a compound die analysis for the part modeled in the sample file sheet metal stamped part.dfmx included with your installa .Design for Manufacturing and Assembly (DFMA) is a critical methodology in product development that focuses on simplifying and optimizing the design of products to improve manufacturability and ease of assembly.(DFMA) guidelines into CAD modeling streamlines the production process for sheet metal fabricators by ensuring designs are optimized for materials, manufacturing techniques, and .

When exporting sheet metal models as DXF or DWG files, map bend line directions to specific layers. This is particularly useful for sheet metal parts with varying bend directions. Enable the Custom Map SOLIDWORKS to . Explores 4 key sheet metal part modeling practices Such as DFMA, MBD, Top-Down & FBPM to reduce fabrication costs of manufacturing projects

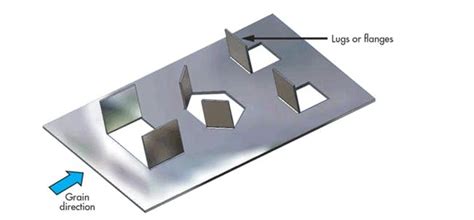

Sheet metal allows the fabrication of large, hollow, covered structures, with minimal waste of material. A carefully designed sheet metal box can be extremely strong and rigid. Attachment points should be located close .

There are 4 sheet metal parts to be welded together. The first process step is to set up the assembly jig to hold the first part. We can start with the opera on of se ng up this jig. Click the . DFMA focuses on simplifying designs and reducing the parts counts. It suggests using standardizing parts so they can be reused over and over in different applications. DFMA also provides.DFMPro for Sheet metal provides sheet metal design guidelines and DFM best practices to produce better quality designs at lower manufacturing costs.

In this tutorial, we follow the steps used to create a turret press and a compound die analysis for the part modeled in the sample file sheet metal stamped part.dfmx included with your installa on (\data\samples) of DFM Concurrent Cos ng. Start a new analysis in DFM Concurrent Cos ng.

Design for Manufacturing and Assembly (DFMA) – an engineering methodology that reduces time-to-market and total production costs by prioritizing ease of manufacturing and efficiency in assembly – is an essential component of any lean manufacturing strategy.Design for Manufacturing and Assembly (DFMA) is a critical methodology in product development that focuses on simplifying and optimizing the design of products to improve manufacturability and ease of assembly.(DFMA) guidelines into CAD modeling streamlines the production process for sheet metal fabricators by ensuring designs are optimized for materials, manufacturing techniques, and assembly. CAD software includes DFM tools that identify manufacturability issues like complex machining areas When exporting sheet metal models as DXF or DWG files, map bend line directions to specific layers. This is particularly useful for sheet metal parts with varying bend directions. Enable the Custom Map SOLIDWORKS to DXF/DWG and select ‘Bend lines’ under ‘Entities to Export’.

Explores 4 key sheet metal part modeling practices Such as DFMA, MBD, Top-Down & FBPM to reduce fabrication costs of manufacturing projects

Sheet metal allows the fabrication of large, hollow, covered structures, with minimal waste of material. A carefully designed sheet metal box can be extremely strong and rigid. Attachment points should be located close to gussets and walls.There are 4 sheet metal parts to be welded together. The first process step is to set up the assembly jig to hold the first part. We can start with the opera on of se ng up this jig. Click the Insert Opera on toolbar bu on. 9. DFMA focuses on simplifying designs and reducing the parts counts. It suggests using standardizing parts so they can be reused over and over in different applications. DFMA also provides.

DFMPro for Sheet metal provides sheet metal design guidelines and DFM best practices to produce better quality designs at lower manufacturing costs.

In this tutorial, we follow the steps used to create a turret press and a compound die analysis for the part modeled in the sample file sheet metal stamped part.dfmx included with your installa on (\data\samples) of DFM Concurrent Cos ng. Start a new analysis in DFM Concurrent Cos ng.

Design for Manufacturing and Assembly (DFMA) – an engineering methodology that reduces time-to-market and total production costs by prioritizing ease of manufacturing and efficiency in assembly – is an essential component of any lean manufacturing strategy.Design for Manufacturing and Assembly (DFMA) is a critical methodology in product development that focuses on simplifying and optimizing the design of products to improve manufacturability and ease of assembly.(DFMA) guidelines into CAD modeling streamlines the production process for sheet metal fabricators by ensuring designs are optimized for materials, manufacturing techniques, and assembly. CAD software includes DFM tools that identify manufacturability issues like complex machining areas

When exporting sheet metal models as DXF or DWG files, map bend line directions to specific layers. This is particularly useful for sheet metal parts with varying bend directions. Enable the Custom Map SOLIDWORKS to DXF/DWG and select ‘Bend lines’ under ‘Entities to Export’. Explores 4 key sheet metal part modeling practices Such as DFMA, MBD, Top-Down & FBPM to reduce fabrication costs of manufacturing projects Sheet metal allows the fabrication of large, hollow, covered structures, with minimal waste of material. A carefully designed sheet metal box can be extremely strong and rigid. Attachment points should be located close to gussets and walls.

sheet metal dfma tricks

electric wooden box heater

electric warmer box

Order junction boxes and other wiring accessories online at BES. Low prices. Free next day delivery available. 15k+ Products in stock. P/N: 22329

dfma of sheet metal parts|dfma for sheet metal