sheet metal stamping mold part quotes Understanding the nuances of acquiring quotes for sheet metal stamping parts is crucial. Here are some decisive factors that could influence the pricing: 1. Material Type: The choice of metal . The Simpson Strong-Tie® TSBR truss spacer-restraint is a time-saving lateral-restraint product that improves quality and safety while helping to meet the prescriptive recommendations of the WTCA/TPI.

0 · short running metal stamping

1 · short metal stamping

2 · sheet metal quotes online

3 · metal stamping near me

4 · how to quote sheet metal

Ultimate Tube Bender Parts, Inc. has been in business since 2000 providing parts, .

short running metal stamping

Sheet Metal Quotes. Highly Durable Metal Parts. Precise Components with Tight Tolerances. Variety of Metals & Alloys with Unique Properties. GET YOUR 30 SECOND QUOTE NOW. Quotes for 25+ Manufacturing Processes. See moreFortunately, Protolabs’ award-winning digital quoting platform reviews your model, offering 3D design for manufacturability feedback followed by real-time pricing for your prototype or low .Understanding the nuances of acquiring quotes for sheet metal stamping parts is crucial. Here are some decisive factors that could influence the pricing: 1. Material Type: The choice of metal .

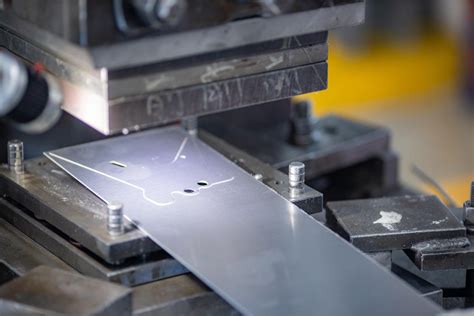

Sheet metal stamping dies are essential tools employed in the stamping process to shape and cut metal sheets into desired forms. They consist of two main parts: the punch and the die. The punch is the component that applies force to the metal sheet, while the die serves as the mold that defines the shape of the final product.

Production: CNC Machining; Sales: 3D Printing Supplier, Sheet Metal Fabrication, Injection Molding Manufacturers/ Suppliers - Dongguan City Longsheng Hardware Technology Co., Ltd. . High Precision CNC Machining Part Mass .

Stamping Part Sheet Metal Fabrication: Material: Sheet Metal,stainless Steel: Surface Treatment: Powdercoated, Polishing, Electroplating: . The size and shape accuracy of metal stamping parts are guaranteed by the mold. Usually, . We will discuss the technical details of sheet metal stamping dies, and how they bring accuracy and consistency to custom sheet metal components. . the part is continuously transferred to the next die automatically or manually if desired for further punches. . You can request stamping service quotes for pricing and other details. .In this blog post, we will explore the importance of obtaining accurate quotes for sheet metal stamping parts from China-based suppliers and highlight the key factors to consider. The Benefits of Sheet Metal Stamping in China. China has a robust manufacturing industry, making it an ideal destination for sheet metal stamping.

Get a sheet metal quotes from a Fathom expert. Fathom can help get your sheet metal project off the ground. . The stamping tool or die contains the desired shape of the part. Stamping may involve punching, blanking, bending, drawing, embossing and more. . The sheet metal part is covered with an even coating of powder and then cured. After .

The best stamped metal part designs take this step-by-step nature of the stamping process into consideration. One of the more substantial forms, often performed toward the end of the progressive die stamping process, is bending. When designing bends into your stamped metal part, it is important to allow for enough materialStamped metal, also known as metal stamping or presswork, is a manufacturing process that involves shaping flat sheet metal into desired components using a stamping press. The press applies force to deform and cut the metal sheet into the desired shape. Stamped metal parts are commonly used in industries such as automotive, aerospace, and .

2021-10-22 Stamping Guide Comments Off on Quotes of sheet metal stamping parts from clients. Here are the quotes of sheet metal stamping part from clients. What stamping part do you need? If you want to know more metal stamping services, welcome .Metal stamping mold ( Metal stamping die) is a kind of special process equipment which processes materials (metal or non-metal) into parts (or semi-finished Call Us: 13530756565 Email: [email protected] sheet metal stamping process is a strategic advantage that can set your business apart. Precision, efficiency, and innovation are at its core, driving the production of high-quality components. . This includes the part’s function, desired material, and specific dimensions. . with the die acting as the mold and the punch forcing the .Our facilities leverage various presses from 30 to 400-ton capacity to produce a wide range of custom metal stamping parts. The metallurgical expertise we use to design our spring and fastener products also extends to stampings, allowing our engineers to create components utilizing materials from low-carbon steel to pre-tempered alloys in thicknesses from .004″ to .

They are interested in metal stamping like stainless steel, tin-coated copper, copper; sheet metal tooling, copper plates, powder coat or paint sheet metal stamping parts. 1. Please could you quote the following quantities of the attached clips: 10000, 100000, 50000 Also if possible could you quote separately for packing into boxes of 100 and .Diving into Deep Drawn Stamping. Deep Drawn Stamping is a metal forming process wherein a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is called “deep drawing” when the depth of the drawn part exceeds its diameter. This method is primarily used for producing hollow or cup-shaped parts.

short metal stamping

Metal stamping encompasses a wide range of metal forming operations like bending, pressing, folding, and stretching, in addition to stamping. All metal stamping processes use punch presses with custom-made tooling and dies to .Decoding the Part Quotes Process . Understanding the nuances of acquiring quotes for sheet metal stamping parts is crucial. Here are some decisive factors that could influence the pricing: . It utilizes mechanical operations to shape metal sheets at high speeds through a stamping machine according to mold design trends, in order to achieve . 9 likes, 0 comments - xm_metalstamping on November 12, 2024: "Sheet metal punching and drilling.Processing of a base part of a household appliance. ️#metalpunching #householdappliances #factory #metalprocessing #sheetmetalfab #metalstampingph #punching #homeappliances #manufacturing".2021-10-22 Stamping Guide Comments Off on Quotes of sheet metal stamping parts from clients. Here are the quotes of sheet metal stamping part from clients. What stamping part do you need? If you want to know more metal stamping services, welcome .

We have a full range of precision machining capabilities, including CNC turning and milling, 3D printing, injection molding, Sheet Metal Fabrication, etc. and many secondary processes. When customers demand high-quality drone components at competitive prices, our precision machining methods deliver impeccable results.

Sheet metal stamping is a metalworking process of shaping metals into desired forms using a punch, blanking die, bending die, and coining die. This technique is commonly used in automotive, medical, and construction industries because it offers a chance to produce many parts at a cheap price.The die block is the part of the die set that holds the metal sheet in place and provides the necessary support and cavity for the operation. It is designed to match the shape of the punch and ensure proper alignment. . Electronics Sheet Metal Stamping Mold; Mobile Phone Card Slot Stamping Die; Our Case Studies Gallery Of Stamping Mold Parts .Below are a few factors machinists consider in their metal stamping cost calculation: 1.Stamping Material. This is a very important factor that fabricatior consider when doing the metal stamping cost calculation. As metal stamping is a subtractive process, it tends to use more material than what will be on the final product.Beska is proud to be ISO 9001:2015 and IATF 16949:2016 certified, showing our dedication to high-quality manufacturing in mold making, injection molding, and sheet metal stamping. The ISO 9001:2015 certification means we have a strong Quality Management System that focuses on improving our processes and keeping customers happy.

What finishing options are available for custom cut sheet metal parts? The cut sheet metal can be finished in several ways such as powder coating, anodizing, or electroplating. These finishing options improve the looks and functionality of the metal parts. Q5. What measures does Prolean Tech take to have quality in custom-cut sheet metal . metal stamping defects include: cracks, wrinkles, folds, Blanking Burrs, uneven stretching, indentations, surface strains and bursting.It is crucial to understand common defects in metal stamping and take preventive measures. . Bursting is a crack or break that forms on the edge or surface of a metal part. It usually occurs in holes, edges .

The surface and internal properties of the sheet metal used for stamping have a great impact on the quality of the stamping product. The thickness of the stamping material is required to be accurate and uniform; the surface is smooth, without spots, scars, scratches, and surface cracks, etc.; the yield strength is uniform and there is no obvious Directionality; high . Sheet metal fabrication and sheet metal forming are sometimes used interchangeably. However, while sheet metal forming specifically refers to the processes that shape flat sheet metal into 3D parts, sheet fabrication is a broader term that includes other processes like cutting and joining to create the final product.

Tuf-Tite 9-Hole Distribution Box comes complete with a lid and your choice of 9 Pipe Seals. Enter the list of your 9 included seals in order notes during check out. Additional seals available for purchase.

sheet metal stamping mold part quotes|short running metal stamping