cnc face milled part Face milling plays a crucial role in the process of aerospace CNC machining where it is used for manufacturing complex parts that fairly require tight tolerances. The accuracy is highly important for aircraft parts in which every . $14.99

0 · online cnc shop

1 · custom milled parts

2 · cnc milling shop

3 · cnc milling service online

4 · cnc milling service near me

5 · cnc mill for prototyping

6 · cnc machine shop websites

7 · cnc machine parts online

$96.99

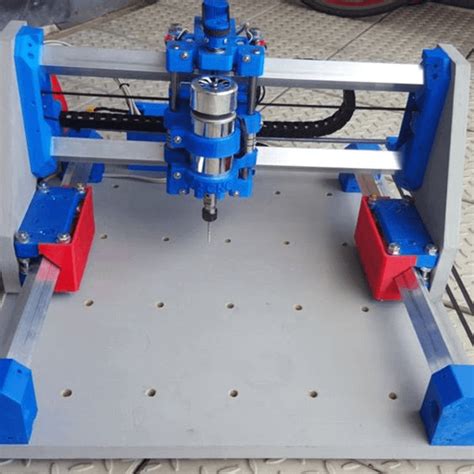

Face milling is a type of milling operation in CNC (Computer Numerical Control) machining. It involves cutting a flat surface, called the "face," on a workpiece to make it . Face milling plays a crucial role in the process of aerospace CNC machining where it is used for manufacturing complex parts that fairly require tight tolerances. The accuracy is highly important for aircraft parts in which every . Face milling is a versatile machining method product engineers use to flatten and smoothen the surface of machined parts. You can use a CNC router, milling machine, or machining center to smoothen these flat surfaces.

Face milling is a key process for smooth surface and precision machining of parts, and selecting the appropriate face milling cutter and optimizing the process are crucial. As a professional milling service provider, .Face milling relies on both the end face of a cutting tool AND the peripheral edges to proceed. A face milling operation allows large areas to be processed with relatively deep cuts, resulting fast processing of simple, flat face cuts. “Face milling is an essential machining process that removes material from a workpiece’s surface to produce a smooth and flat finish. It’s highly efficient for creating precise and uniform surfaces on large and flat areas.” . Face milling is a type of milling operation in CNC (Computer Numerical Control) machining. It involves cutting a flat surface, called the "face," on a workpiece to make it smooth. In face milling, a tool with rotating cutting edges moves across the workpiece, shaving off thin layers. Face milling is important because it is efficient and versatile.

Face milling plays a crucial role in the process of aerospace CNC machining where it is used for manufacturing complex parts that fairly require tight tolerances. The accuracy is highly important for aircraft parts in which every micron points to . Face milling is a versatile machining method product engineers use to flatten and smoothen the surface of machined parts. You can use a CNC router, milling machine, or machining center to smoothen these flat surfaces. Face milling is a simple procedure that mostly works for smoothening and finishing the surface of parts. While machinists commonly use various face mills, finding the best type to work with a face milling procedure is essential. Face milling is a key process for smooth surface and precision machining of parts, and selecting the appropriate face milling cutter and optimizing the process are crucial. As a professional milling service provider, BoYi can efficiently handle the milling needs of customized plastic and metal parts, whether it is prototype production or mass .

Face milling relies on both the end face of a cutting tool AND the peripheral edges to proceed. A face milling operation allows large areas to be processed with relatively deep cuts, resulting fast processing of simple, flat face cuts. “Face milling is an essential machining process that removes material from a workpiece’s surface to produce a smooth and flat finish. It’s highly efficient for creating precise and uniform surfaces on large and flat areas.” CNC Milling is one of the key machining processes in manufacturing known for high precision and complexity.

In this article, I want to talk about the face milling operation. Facing operation is one of the common operations which you can do on CNC machines. Everywhere, every workshop shop has dedicated face milling heads and these face milling heads . Face milling uses the flat surface of the tool to create smooth, flat surfaces and grooves, while end milling employs the tool’s end to cut complex shapes and profiles. Face milling is ideal for large surfaces, whereas end milling excels in versatility and intricate geometries.Face milling is the most common milling operation, and can be performed using a wide range of different tools. Cutters with a 45º entering angle are most frequently used, but round insert cutters, square shoulder cutters, and side and face mills are also used for certain conditions.

Face milling is a type of milling operation in CNC (Computer Numerical Control) machining. It involves cutting a flat surface, called the "face," on a workpiece to make it smooth. In face milling, a tool with rotating cutting edges moves across the workpiece, shaving off thin layers. Face milling is important because it is efficient and versatile. Face milling plays a crucial role in the process of aerospace CNC machining where it is used for manufacturing complex parts that fairly require tight tolerances. The accuracy is highly important for aircraft parts in which every micron points to . Face milling is a versatile machining method product engineers use to flatten and smoothen the surface of machined parts. You can use a CNC router, milling machine, or machining center to smoothen these flat surfaces.

Face milling is a simple procedure that mostly works for smoothening and finishing the surface of parts. While machinists commonly use various face mills, finding the best type to work with a face milling procedure is essential.

Face milling is a key process for smooth surface and precision machining of parts, and selecting the appropriate face milling cutter and optimizing the process are crucial. As a professional milling service provider, BoYi can efficiently handle the milling needs of customized plastic and metal parts, whether it is prototype production or mass .Face milling relies on both the end face of a cutting tool AND the peripheral edges to proceed. A face milling operation allows large areas to be processed with relatively deep cuts, resulting fast processing of simple, flat face cuts.

“Face milling is an essential machining process that removes material from a workpiece’s surface to produce a smooth and flat finish. It’s highly efficient for creating precise and uniform surfaces on large and flat areas.” CNC Milling is one of the key machining processes in manufacturing known for high precision and complexity.

In this article, I want to talk about the face milling operation. Facing operation is one of the common operations which you can do on CNC machines. Everywhere, every workshop shop has dedicated face milling heads and these face milling heads . Face milling uses the flat surface of the tool to create smooth, flat surfaces and grooves, while end milling employs the tool’s end to cut complex shapes and profiles. Face milling is ideal for large surfaces, whereas end milling excels in versatility and intricate geometries.

newspaper metal boxes

online cnc shop

custom milled parts

$89.99

cnc face milled part|custom milled parts