5-axis cnc integrated machining equipment With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis . Stainless steel can be welded using any arc welding process such as MIG, TIG, Stick & Flux-cored. Each process will yield a slightly different result and will require some learning and skill to accomplish.

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · benefits of 5 axis machining

4 · 5 axis trunnion machining

5 · 5 axis machining explained

6 · 5 axis machining basics

7 · 5 axis cnc explained

The practical lower metal thickness limitation for flux-cored wire is around 18 GA steel. For autobody sheet metal, the more pratical solution is to use a welder that can use solid wire with C25 shielding gas. The Handler 140 would be a good welder if 115V service is desired. The Handler 187 would be a good solution if 230V service is desired.

This new control series advances machine performance with 5-axis integrated technology and supports both machine tool builders and CNC users with their evolving needs .FANUC helps take the complexity out of 5-axis machining. With up to 52 years .5-axis machining is easier and less expensive than you think, and can dramatically increase your profits. This versatile 5-axis universal machining center can position parts to nearly any angle .With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis .

what is 5 axis milling

what does 5 axis mean

Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along .FANUC helps take the complexity out of 5-axis machining. With up to 52 years MTBF, FANUC CNC Systems are not only the most reliable in the industry, but are also powerful 5-axis .

Multi-sided machining and complex 3D curved surface processing with simultaneous 5-axis control are possible with a single setup. A wide variety of machine specifications - from 2-axis models to turning centers with rotary tool .

The DA500, like the smaller DA300, is inspired by the best design characteristics from both vertical and horizontal machining platforms, the DA500 is one of the first general production .

This new control series advances machine performance with 5-axis integrated technology and supports both machine tool builders and CNC users with their evolving needs .Multi-face machining and simultaneous 5-axis machining with one chucking ; Wide variety of table sizes, spindles, and automation systems; Turning capability for further process integration (i-700T, i-800T, i-1050T)The Takumi U800 is a 5-axis, high-speed, CNC machining center that produces outstanding surface finish and is great for aerospace and automotive industries.

This new control series advances machine performance with 5-axis integrated technology and supports both machine tool builders and CNC users with their evolving needs including easier operations, more security and optimized efficiency.

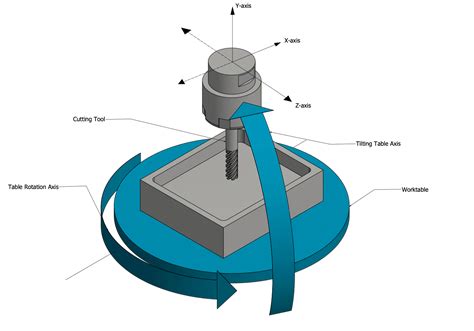

5-axis machining is easier and less expensive than you think, and can dramatically increase your profits. This versatile 5-axis universal machining center can position parts to nearly any angle for 5-sided (3+2) machining, or provide simultaneous .With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis simultaneous milling of . Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle .FANUC helps take the complexity out of 5-axis machining. With up to 52 years MTBF, FANUC CNC Systems are not only the most reliable in the industry, but are also powerful 5-axis controls with advanced functions for optimal 5-axis tool paths.

Multi-sided machining and complex 3D curved surface processing with simultaneous 5-axis control are possible with a single setup. A wide variety of machine specifications - from 2-axis models to turning centers with rotary tool spindle and second spindle - is available.The DA500, like the smaller DA300, is inspired by the best design characteristics from both vertical and horizontal machining platforms, the DA500 is one of the first general production machines capable of both milling and turning with a high degree of reliability and agility to improve production efficiency. This new control series advances machine performance with 5-axis integrated technology and supports both machine tool builders and CNC users with their evolving needs including easier operations, more security and optimized efficiency.

small 5 axis cnc mill

Multi-face machining and simultaneous 5-axis machining with one chucking ; Wide variety of table sizes, spindles, and automation systems; Turning capability for further process integration (i-700T, i-800T, i-1050T)

The Takumi U800 is a 5-axis, high-speed, CNC machining center that produces outstanding surface finish and is great for aerospace and automotive industries. This new control series advances machine performance with 5-axis integrated technology and supports both machine tool builders and CNC users with their evolving needs including easier operations, more security and optimized efficiency.

5-axis machining is easier and less expensive than you think, and can dramatically increase your profits. This versatile 5-axis universal machining center can position parts to nearly any angle for 5-sided (3+2) machining, or provide simultaneous .

With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis simultaneous milling of . Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle .FANUC helps take the complexity out of 5-axis machining. With up to 52 years MTBF, FANUC CNC Systems are not only the most reliable in the industry, but are also powerful 5-axis controls with advanced functions for optimal 5-axis tool paths.Multi-sided machining and complex 3D curved surface processing with simultaneous 5-axis control are possible with a single setup. A wide variety of machine specifications - from 2-axis models to turning centers with rotary tool spindle and second spindle - is available.

The DA500, like the smaller DA300, is inspired by the best design characteristics from both vertical and horizontal machining platforms, the DA500 is one of the first general production machines capable of both milling and turning with a high degree of reliability and agility to improve production efficiency. This new control series advances machine performance with 5-axis integrated technology and supports both machine tool builders and CNC users with their evolving needs including easier operations, more security and optimized efficiency.Multi-face machining and simultaneous 5-axis machining with one chucking ; Wide variety of table sizes, spindles, and automation systems; Turning capability for further process integration (i-700T, i-800T, i-1050T)

Welding 16ga steel with .030 self shielding flux core wire should be fairly easy after a little practice. 18ga should be just as easy. Make some welds on coupons and bend test after you start getting good looking welds is a reality check. Poor fusion is .

5-axis cnc integrated machining equipment|5 axis cnc explained