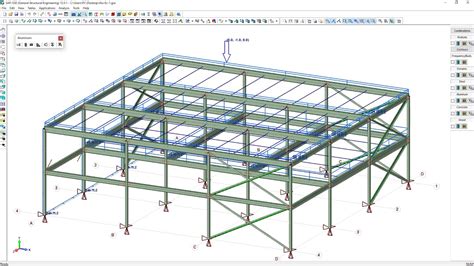

aluminum structure design and fabrication The guide addresses the following subject areas: material characteristics and properties, structural design, fatigue design and analysis procedures, typical structural details used for aluminum, welding and fabrication of aluminum, joining to steel structure, residual stresses and distortion of aluminum structure, fire protection, vibration . What happens when water gets inside an electrical outlet? When water gets inside an electrical outlet, there’s a danger, end of story! Not only will the outlet stop working but there’s also a high risk of electrical shock, burns, and short circuits.

0 · aluminum structure design pdf

1 · aluminum structure design manual

Mount your Panhard bar with a precision machined JOES Panhard Mount. Just loosen the bolt (s) and slide the JOES Panhard. Steel brackets can be used as front mount for leaf spring or trailing arm. Dimensions: ⅝” Slot ³/₁₆” Thick 3¾” Locate your car’s third member securely with a pair of JOES 3rd Mounts. Made from 6061-T6 aluminum. Sold in pairs.

The guide addresses the following subject areas: material characteristics and properties, structural design, fatigue design and analysis procedures, typical structural details used for .

The original study dealt with only the aluminum bottom and side structure. .

Updated every five years, the Manual includes the Specification for Aluminum Structures which provides for allowable strength and load and resistance factor design of aluminum structures, .

Specification for Design and Fabrication of Aluminum Alloy Structures in Civil Engineering was published by the Light Metal Association in 1977, and a revised version was published by the .The guide addresses the following subject areas: material characteristics and properties, structural design, fatigue design and analysis procedures, typical structural details used for aluminum, welding and fabrication of aluminum, joining to steel structure, residual stresses and distortion of aluminum structure, fire protection, vibration .Updated every five years, the Manual includes the Specification for Aluminum Structures which provides for allowable strength and load and resistance factor design of aluminum structures, members, and connections.Specification for Design and Fabrication of Aluminum Alloy Structures in Civil Engineering was published by the Light Metal Association in 1977, and a revised version was published by the Japan Aluminum Association in 1998, but the basics

The original study dealt with only the aluminum bottom and side structure. Requirements for hull girder section modulus midships, and plate thickness, stiffener and transverse frame section modulus at the LCG, and several other points along the hull were given.The original study dealt with only the aluminum bottom and side structure. Requirements for hull girder section modulus midships, and plate thickness, stiffener

aluminium structures in buildings, civil and structural engineering works such as bridges, hydraulic and offshore structures and temporary structures, e.g. erection and building scaffolds, masts, cable- and light poles.Keyed to the revised Specification for Aluminum Structures of the 2000 edition of the Aluminum Design Manual, it provides quick look-up tables for design calculations; examples of recently. The next edition of the Aluminum Association’s Aluminum Design Manual (ADM): Updated every five years. Includes the Specification for Aluminum Structures which provides for allowable strength and load and resistance factor design of .

operation and maintenance of aluminum structures for ships and craft are reviewed to assess the needs for improvements in that technology. The areas reviewed are: material property and behavior, structural design, structural details, welding and fabrication, joining aluminum to steel, residual stresses and distortion, Thoroughly up-to-date, this book describes advanced design techniques that have been used in successful aluminum structures, including a step-by-step design process for each of several.The guide addresses the following subject areas: material characteristics and properties, structural design, fatigue design and analysis procedures, typical structural details used for aluminum, welding and fabrication of aluminum, joining to steel structure, residual stresses and distortion of aluminum structure, fire protection, vibration .Updated every five years, the Manual includes the Specification for Aluminum Structures which provides for allowable strength and load and resistance factor design of aluminum structures, members, and connections.

name of slums houses made of metal

Specification for Design and Fabrication of Aluminum Alloy Structures in Civil Engineering was published by the Light Metal Association in 1977, and a revised version was published by the Japan Aluminum Association in 1998, but the basicsThe original study dealt with only the aluminum bottom and side structure. Requirements for hull girder section modulus midships, and plate thickness, stiffener and transverse frame section modulus at the LCG, and several other points along the hull were given.

The original study dealt with only the aluminum bottom and side structure. Requirements for hull girder section modulus midships, and plate thickness, stiffener

aluminium structures in buildings, civil and structural engineering works such as bridges, hydraulic and offshore structures and temporary structures, e.g. erection and building scaffolds, masts, cable- and light poles.

nanonine insulated stainless steel lunch box

Keyed to the revised Specification for Aluminum Structures of the 2000 edition of the Aluminum Design Manual, it provides quick look-up tables for design calculations; examples of recently. The next edition of the Aluminum Association’s Aluminum Design Manual (ADM): Updated every five years. Includes the Specification for Aluminum Structures which provides for allowable strength and load and resistance factor design of .operation and maintenance of aluminum structures for ships and craft are reviewed to assess the needs for improvements in that technology. The areas reviewed are: material property and behavior, structural design, structural details, welding and fabrication, joining aluminum to steel, residual stresses and distortion,

aluminum structure design pdf

aluminum structure design manual

navy with metallic pattern fabric

Is the guage numbering (thickness) for wires and sheet metal the same? Sheetmetal guage is called the U.S. Standard Gauge which the photo is showing. Its used for .

aluminum structure design and fabrication|aluminum structure design manual