how to fabricate a cone with sheet metal Layout of a cone template for sheet metal fabrication. Stephen Marchio. 7.25K subscribers. 758. 99K views 4 years ago. Introduction. In this article, we'll explore the different types of CNC machines and how they're used to achieve high precision, increased productivity, enhanced design flexibility, reduced waste, and improved safety in modern manufacturing. Basic Types of CNC Machines.

0 · truncated cone from flat sheet

1 · sheet metal transition layout

2 · sheet metal cone rolling calculation

3 · sheet metal cone formula

4 · sheet metal cone fabrication

5 · creating a cone layout

6 · cone sheet metal calculator

7 · cone layout formula

Ground screws for electrical boxes are typically 10-32. When working with electrical boxes, it is crucial to use the correct screw size and type to ensure a safe and secure installation.

truncated cone from flat sheet

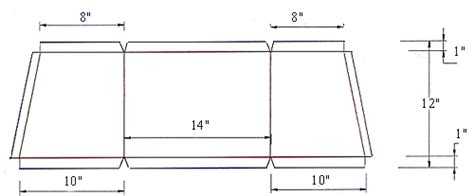

Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions. Layout of a cone template for sheet metal fabrication. Stephen Marchio. 7.25K subscribers. 758. 99K views 4 years ago.

Here is one way to make a cone from flat stock. I used aluminum sheet coil but you could use paper or any flat material. You can find cone calculators online, I used this particular cone.

power distribution box 120 240vac voltage rating 30 amps

The first step in fabricating a cone with sheet metal is to choose the right material. Sheet metal comes in a variety of materials, including steel, aluminum, and copper. The material chosen will depend on the application . Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It .The first step in fabricating a cone from sheet metal is determining the dimensions of the cone you want to create. This includes the base diameter, top diameter (if it's a frustum), and the height .Step 1: Draw Elevation View & Plan View for Full Cone Shape. Step 2: Divide Top View Circle of Cone in equal no. of Parts. Step 3: Measure Slant Height of the Cone in elevation view. Step 4: Draw Development Circle with Radius as Slant .

Whether you need to replace a damaged cone or create a custom design for your project, learning how to make a sheet metal cone can save you time and money. In this step . How To Build A Steep Cone in Sheet Metal. Here's the build of part of the ether cone as seen in the previous "How To Make A Sheet Metal Pattern From Scratch" video I posted.

Your sheet metal cone is now complete and ready for use in your project. In this guide, we've covered the essential steps for fabricating a sheet metal cone. With the right tools, materials, .Cone Layout Development by Marking and Calculation Method with Practical Example. Full Cone is a very common shape in fabrication industry as it is most frequently used shape in fabrication so it is very necessary that every .

This video shows how to make cones from 1/8-inch (3.2mm) steel, using simple shop-made equipment. You can help me create new videos by becoming a Patreon. He.This cannot directly make a conic bend though. You may be better off measuring the length of what will become the circular top and circular bottom of the cone from the flat pattern then use that to construct the cone directly as a 3D sheet metal piece to flatten (like this: GoEngineer - SOLIDWORKS: Sheet Metal Cone). #MetalFabricationTips #MetalFabTips #KevinCaronArtFrom http://www.kevincaron.com - Artist Kevin Caron shows the easy way he found to make a cone for his late.The workshop has this piece of machinery that rolls sheet metal to bend it to a curve, but as far as I can tell it will only produce a curve in one way. So a cone would be fine, but the parabolic shape requires curves in two directions and I'm not sure how that's gonna happen.

In this video, I show how to make a reducer from sheet metalHow to fabricate sheet metal. As explained, sheet metal fabrication is a complex process that requires years of training and experience to perfect. It involves multiple stages, starting with design. If you’re keen to learn more about sheet metal fabrication, discover more about it in our ultimate guide to sheet metal fabrication here. Step 1 .

About Sheet Metal ConesSheet metal cones are commonly used in a variety of industrial and commercial applications, including ductwork, chimneys, and tanks. Fabricating a cone with sheet metal requires precision and expertise. In this blog post, the experts at Vishwambhari Engineering will guide you through the steps we take when fabricating a cone .

Video title: How to Roll a Cone – Midland FabricationIn this video students James & Luke talk us through how to roll a cone in a set of pinch plate rolls. Th.

Creating a Sheet metal cone in SOLIDWORKS can seem like a complex task, but I’m here to alleviate your worries and provide you with the correct workflow. I typically like to start my first sketch on the Top Plane. Using my sheet metal open sketch technique, we can draw an arc and its construction lines. With the radius (or diameter) dimension .This calculator is useful for fabrication Industry, Process Equipment Manufacturing Industry, Pressure Vessel Manufacturing Industry, Piping Industry, Sheet Metal Industry, Heavy Equipment Fabrication Industry or any similar Industry where cone fabrication works involved.SolidWorks Tutorial Sheet Metal Cone Tutorial video how to make cone in solidworks Sheet metal cones are versatile and indispensable in a wide range of applications, from ductwork in HVAC systems to chimney caps and funnels. Whether you need to replace a damaged cone or create a custom design for your project, learning how to make a sheet metal cone can save you time and money. In this step-by-step guide, we will walk you through the .

Cone sheet metal fabrication is a versatile technique that allows for the creation of precise conical shapes, making it useful in a wide range of industries and applications. The ability to customize the dimensions and angles of the cones makes it a valuable tool for engineers and designers looking to optimize the performance of various systems .This development Angle is used to layout cone fabrication layout markings or Flat Pattern Markings. Refer to Standard Image for understanding these dimensions at Output sections. . Piping Industry, Sheet Metal Industry, Heavy Equipment . SolidWorks II Sheet Metal II Four Ways To Create Sheet Metal - ConeIn this video, I am going to explain Four difference ways to create Sheet Metal - Cone----.

In this video I make a sheet-metal slip roll for shaping cones and cylinders. The tool I made is quite small, but yet very rigid due to the variable width de. Make a straight line on the cone from the top to the bottom. Place the cone back onto the construction paper, with the line you drew facing up. Wrap the paper around the cone. With a pencil, make a line from the top of the cone to the bottom, on the construction paper where the paper overlaps the line on the cone.

Here a video how to make an Eccentric Reducer •you need to build your cylindrical or conical shape in the sheet metal environment. I've read and understood the 6 rules of Sheet Metal. But I can't figure out how to make a cone in Sheet Metal. (I can make cones all day in Model, but they won't flatten/unwrap)

This Solidtec - SolidWorks tip demonstrates how to produce a Sheet Metal cone in SolidWorks using the Lofted-Bend tool, then export the flat pattern to dwg o. I've only had a little work with sheet metal and I've just bullied it into the right shape with a hammer usually. What I'm looking for is a way to make a large radius half-sphere. . it's more of a heavily filleted cone. The method Reis describes what armorers use and that is what you need here since it's actual (fantasy) armor. With these .

This Tutorial is about how to design a Cone of Sheet Metal in SOLIDWORKS. Lofted Bend and Flatten commands are used for this design. Flattened view shows ho.

•you need to build your cylindrical or conical shape in the sheet metal environment. I've read and understood the 6 rules of Sheet Metal. But I can't figure out how to make a cone in Sheet Metal. (I can make cones all day in Model, but they won't flatten/unwrap)Rolling a metal cone out of sheet metal may be a little easier than you may think. By determining the length of the slanted side and the circumference at the wide end of your cone, you can quickly and easily produce a cone exactly the size you want it to be out of a flat piece of sheet metal.how to build a cone? complete Method to make templateA concentric reducer is used to join pipe sections or tube sections on the same axis.The concentric redu.Beginning with a plain piece of 22 gauge stainless steel sheet metal, I demonstrate how to roll a cone. One side of the roller is compressed more than the o.

power distribution unit boxes

Sheet metal is metal formed by an industrial process into thin, flat pieces. It is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of

how to fabricate a cone with sheet metal|sheet metal cone fabrication