junction box diy A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings. These 21 Tools are important for every metal worker, whether you own your shop or even just have a strong hobby and desire to learn metal working. Some of the tools listed are wants over needs, but overall, they are all tools that should end up .

0 · wiring a junction box diagram

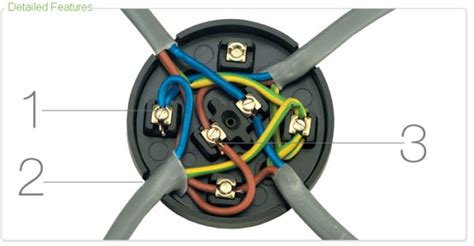

1 · terminal junction box wiring guide

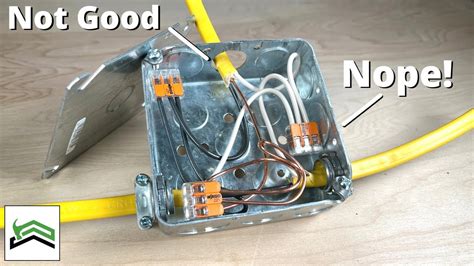

2 · junction box wiring problems

3 · junction box wiring instructions

4 · electrical junction box instructions

5 · connecting wires in junction box

6 · 6 terminal junction box wiring

7 · 3 terminal junction box wiring

Sheet metal hemming is a standard method for improving the quality and appearance of your sheet metal products. This article discusses the principle behind sheet metal hemming, its purpose, and how you can get the best from it. You’ll also learn the types of sheet hems alongside the advantages and disadvantages of the process.

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings. If your house has visible wiring splices or if you need to add a new splice to extend a circuit, follow these simple steps to install a junction box.

Installing an electrical junction box is a handy skill for any homeowner to know. Check out this video where we walk you through how to install an electrical junction box step by step.. One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing .

Take a disposable food storage container and drill a hole in each side. Then cut a slit down to the hole. Tie the 2 extension cords together and plug them into each other as . An electrical junction box is a safety box used to cover wires that have been joined in a single electrical unit. An electrical junction box can either be made of metal or plastic. To save on costs, plastic junction boxes offer a .

Then mount an octagon box to that. If you need a deeper box. Buy a box extension. Should be near the electric boxes. You can use plastic if you wish. Set your brace in the wall so your box sits flush or slightly behind the exterior sheathing. You will need to kill power to push the wires into the box as well as connect the fixture.Junction boxes merely need to be "accessible", whereas breaker panels have to be "readily accessible". A junction box in an unfinished attic would be "accessible" for NEC purposes since one can access it without altering the building structure or finish.

The LeMotech Waterproof Dustproof IP67 Junction Box DIY Case Enclosure in Gray offers robust protection and versatility for various electrical and outdoor applications. Here's a review: Durable Construction: Crafted from high .

I have a pair of junction boxes that's half buried in dirt. They have been there since I don't know when several owners ago perhaps installed in 1990s. . Electrical HVAC Building & Construction Plumbing General DIY Discussions. Top Contributors this Month View All. Nealtw 1064 Replies. chandler48 985 Replies. DoomsDave 396 Replies . Secure the Box: Place the junction box over the mounting holes and fasten it securely using appropriate screws or fasteners, ensuring the box is level and flush with the surface. Connecting Wires Once the junction box is securely mounted, the next step involves connecting the electrical wires. High quality IP66 ABS DIY Waterproof junction box, Multifunction electrical Splitter box, Waterproof, dustproof, safety, environmental protection, widely used for home improvement, outdoor, hotels, factories, school, List Model Qty. Junction Box 120*120*80mm(L*W*H) 1 Terminal UK2.5B(800V,32A) 10 35mm DIN Rail 1 Cable Gland M20(Wire rang:6-12mm) 3 Fastener 2 . LeMotech IP67 Waterproof Junction Box ABS Plastic Project Box Dustproof Electrical Box Outdoor Enclosure for Electronics DIY Case Gray 3.9X 3.9X 3 inch (100x 100x 75 mm) 4.6 out of 5 stars 939 1 offer from 9 $ 9 39

Junction Box. Jump to Latest . DIY Home Improvement Forum. 3.2M posts 334.4K members Since 2003 A forum community dedicated to Do it yourself-ers and home improvement enthusiasts. Come join the discussion about tools, projects, builds, styles, scales, reviews, accessories, classifieds, and more! Helping You to Do It Yourself!

diamond plate steel tool box

wiring a junction box diagram

The existing light will be removed and the existing metal junction box will have a white cover plate. I am using a 3/8 inch flexible metal conduit whip ( Southwire 3/8 in. x 6 ft. 14/3 Solid CU Lighting Flexible Whip-55082415 - The Home Depot ) to do this. When i took the light fixture off i noticed that the junction box did say that it was ok for ceiling fans and noticed that it was right on the beam. To attach the ceiling fan to the mount i have to screw it dirextly into the beam. My question is do you think a ceiling fan will hold up being screwed in directly into the beam instead of the .

Honestly you probably will not get into the junction boxes frequently you may want to use a type T conduit body instead of actual junction boxes. It should be noted that MC4 connectors are not rated to be put in an enclosed box, they require free flowing air to keep cool.Features and benefits. Comes with: 4xM20 cut-outs (1 each side), 1xM25 cut-out on rear with sealant ring; Fixings supplied: Fixings not supplied; Durability: Will not crack or fade in sunlight From that side, I pulled the wires from the old outlet box, pried the box off the stud, and then installed a metal junction box facing the garage. Fed the wires in through a strain relief, wirenutted the hots, the neutrals, and screwed the ground to the box. . DIY Home Improvement Forum. 3.2M posts 337.1K members

I'm just wondering if there is a preference for mounting the junction box in the cabinet for extending the wiring, whether an access hole in the back of the cabinet or an extension ring to make the blank plate of the junction box flush with the cabinet is preferred. . DIY Home Improvement Forum. 3.2M posts 337.1K members Since 2003 A forum .

Yes, it would be against code to have a cabinet cover the junction box. Anywhere you connect wires to wires, or wires to fixtures, the connection needs to be accessible. Since your cabinet would be permanently affixed to the wall and covering the junction box, it wouldn't be allowed. You'd have to run a new uninterrupted cable to the newer . Only if you can open the cabinet and see the junction box. Otherwise, it is illegal in the scope, due to you have to remove the microwave to get to the junction box. It would be the same as installing a cabinet, and not cutting an access hole where a . I need to move this junction box to the right about 30 inches to center it above a new vanity. The current location of the junction box would hide it behind a new linen tower. . DIY Home Improvement Forum. 3.2M posts 337K .

1.Waterproof/Dustproof junction boxes, perfect for use outdoors, 2.Junction box means these are well protected from rain and water splash back, making them perfect for joining wires inside. 3.Easy to install and easy to use. 4.100% brand new and high quality. Package Include: 1 x Electrical Junction Box 4 x Metal Screws(Not Rustproof) Code punishes you for having more than 12" of free wire length inside the box (it requires another "wire count" for box fill purposes). so my answer is 11.999 inches. You must also have >3" of free wire length beyond the surface of the wall. So if your wire is barely 6" long in a 3.5" depth box, you only have 2.5" beyond the wall surface, whoops!

The black box has a quarter-size hole in the side, letting in weather and wasps. A new box top lists for the same or more than the cost of a whole new assembly. I assume this Pentair 78310700 Junction Box with Cover, 3/4 inch and 1 inch Ports is .

The master electrician told me that instead of extending each electrical wire, a junction box is used. Its the professional way of doing it, he said. It makes sense. But the question is, if the panel was not allowed to be in the bathroom, is it different for a junction box? To me, the junction box simply extends existing electrical wiring. The cable for each light box goes through a conduit and up to a "deck Box" or junction box per code so water from pool can't run up to the box. In order to change the lights we need to locate the box and pull the wires out, then feed the wires through for the new light. The problem is that one of the boxes seems to be missing.

terminal junction box wiring guide

35 votes, 58 comments. 25M subscribers in the DIY community. DIY. Skip to main content. Open menu Open navigation Go to Reddit Home. r/DIY A chip A close button. Get . In offices, junction boxes are usually in the ceiling, above the t-bar. But they are accessible by moving the ceiling tile. Or in a drywall ceiling, an access panel has to be . New here, and without much electrical experience, but still alive. Bought a new combo wall oven/microwave (combo units are ridiculously expensive but had no alternatives) and need to move the wall junction box to accommodate clearance issues (the issue is the strain relief fitting at junction box outlet in the wall that forces the wall oven/mw out about half an inch from . 【Easy for DIY】- This sturdy junction box can be drilled and shaped easily without cracking, so it’s also suitable for your various DIY projects. 【Wild Application】Widely used for electronic projects, instrument enclosure, power supply units, temperature controller box, etc.****Package Content : 2 x Waterproof Junction Box**** .

This item: Jutagoss Blue Metal Electric Enclosure Junction Box DIY Project Box Preventive Case Electrical Box 6.69"x5.12"x3.15" 1PCS . .99 $ 20. 99. Get it Oct 29 - Nov 12. Usually ships within 9 to 10 days. Ships from and sold by Jutagoss US. + Some junction boxes were only made to support a standard light fixture when they were installed. Since a ceiling fan is much heavier, make sure the mounting screws are long enough (and there is more than one) to support the weight. . DIY Home Improvement Forum. 3.2M posts 337.1K members

di2 rs910 junction box

Types of Corner Brackets. There are several different types of corner brackets available: 1. L-shaped Bracket – The most common type used in woodworking projects which comes in variety of sizes depending on application. 2. T-shaped Bracket – Used when perpendicular intersection causes space issues. 3.

junction box diy|junction box wiring instructions