fusion 360 curved sheet metal 1. Set sheet metal rules (thickness, material) 2. Draw curve in sketch. 3. Use flange tool to extrude. 4. Use extrude tool to create short flat extrusion on end. 5. Unfold? How? Thanks! Report.

Retractable Awnings Mounting Bracket - Heavy Duty Awning Brackets, Replacement Parts Awning Holder Brackets, Awning Mounting Bracket Patio Hardware Mounting Brackets for Retractable Awnings Shades

0 · fusion 360 unfold sheet metal

1 · fusion 360 sheet metal thickness

2 · fusion 360 sheet metal rules

3 · fusion 360 sheet metal hem

4 · fusion 360 sheet metal drawing

5 · fusion 360 sheet metal design

6 · fusion 360 sheet metal basics

7 · autodesk fusion 360 sheet metal tutorial

Allen Company Classic Steel Ammo Box - Large, Lockable, And Waterproof Ammo Storage For .30 Cal. - Shooting Accessories - Army Green Metal Container 10 4.4 out of 5 Stars. 10 reviews Save with

fusion 360 unfold sheet metal

This angle ring is very easy to model using the revolve command and then add some flange holes. You can call the material out as sheet metal if you desire. It can also be created as a sheet metal component in Fusion 360 . This video walks through the process of taking a standard solid part that has curves to it that needs to be laser cut and flattens it using the convert to Sh.

I'm trying to create a curved sheet metal part. I will be rolled manually, but I need to know the unfolded shape to have it cut. I'm starting with the sketches, one above the other.

add metal gang box on top of existing box

Autodesk 360 Sheet Metal - Flat Pattern on Curved Surfaces. John Hackney. 2.75K subscribers. Subscribed. Wrap Text To Curve with Sheet Metal - Fusion 360. thehardwareguy. 61.1K subscribers. Subscribed. 72. 1.9K views 4 years ago #sheetmetal #fusion360 #autodesk. My Fusion 360 Course:. 1. Set sheet metal rules (thickness, material) 2. Draw curve in sketch. 3. Use flange tool to extrude. 4. Use extrude tool to create short flat extrusion on end. 5. Unfold? How? Thanks! Report.The Fusion Sheet Metal skill path gives you the fundamentals for working with sheet metal. Learn to create flat patterns from 3D models, work with all sorts of bends, customize your materials, .

Solution: Only sheet metal components can be flattened (unfolded) in Fusion. Check the following: Convert to Sheet Metal. Unfold sheet metal features. Autodesk Inventor .On the Sheet Metal toolbar, Create group, click New Component. In the New Component dialog, the Type defaults to Sheet Metal. Decide if the component will be an External or Internal .

In this Fusion 360 Tutorial I cover how to use the Bend feature. It is a really simple tool that can make modeling sheet metal vary simple. *These Fusion 360 tutorials are meant to. Thanks for posting on the Fusion forum. here is the link for How to create a flat pattern in Fusion 360 for a sheet metal part imported from another software. Please take a look into it and accept the solution if it works.-----

Something like this, I've downloaded a trial for Rhino3d and couldn't do the same with fusion. Imagine two curved lines joined with a loft. This is a fully developed surface, meaning it was able to flatten out without any stretching / . Solved: I'm trying to create a curved sheet metal part. I will be rolled manually, but I need to know the unfolded shape to have it cut. I'm starting. Fusion. For teams; By role. Machinist; . Fusion 360 Product Support. . Support us- https://www.paypal.me/supportsparkplug Hello there,does anyone know how I could achieve this result in Fusion 360? I have to add flanges to a curved sheet metal as in the photo. My goal is to have a proper flat pattern output at the end of my modeling. In real life you need to have those multiple cuts along the curved profile to allow flanges to bend.But since Fusion doesn't allow to add flanges to a .

Learn how to create different types of sheet metal flanges in the Design workspace in Fusion.. Create a base flange. On the Sheet Metal tab, select Create > Flange.. The Flange dialog displays.. In the dialog, select the Edge Flange type.. In . Have a tricky question about a Fusion (formerly Fusion 360) feature? Share your project, tips and tricks, ask questions, and get advice from the community. Learn & Support . so I would like to try making the same part using the sheet metal tools. However I cannot figure out how to change the angle of the next flange? Tags (2) Tags: curve .

In a previous video linked below, I showed a process to create a paper template to make tubing notches. Since that video, Autodesk has added some functionali.

*** skip the countdown 3:15 ***In this LiveStream, come see how to manually create bent HVAC-type parts in Fusion 360 Sheet Metal, such as going from a recta.

Only posts directly related to Fusion are welcome, unless you're comparing features with other similar products, or are looking for advice on which product to buy. Please assume that all posts are [serious] by default, and try to respond with serious comments if at all possible. For someone who may be taking that first step into having a sheet metal design created, here are the ESSENTIAL things that your drawing needs before sending . I am facing issue of of 2 flange corner and edge overlapping or edge seam in fusion 360 sheet metal. I am currently using Creo 2.0 where we have edge treatment option to control the overlap of the edges and also have option to make corner relief as zero. Will you please tell me how to make such parts in sheet metal of fusion 360 Note that I set my sheet metal thickness to 1/8", and then matched the overlap spacing with an extra thousandth to prevent self-intersecting geometry. Note how I messed with the exact length of the overlap by controlling an angle, such that the corner of the underlapping end wouldn't intersect the inside radius of the overlapping end's bend.

Hi - I'm making sheet metal flower petals that will be laser cut. -Can Fusion work with curved metal? -I would like some advice on workflow. Screencast here -What is the difference between unfold and flat pattern? The petals are curved - here is one This is my workflow (screencast) 1. Set sheet metal rules (thickness, material) 2. In this quick tip, we will cover some best practices with sheet metal in Fusion 360. Rule 1, flat patterns, and flange options are just a few of the tips cov. Share Fusion (formerly Fusion 360) issues here and get support from the community as well as the Fusion team. cancel. Turn on suggestions. Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type. . Convert Curved Surface to Sheet Metal then generate a Flat Pattern

Creating sheet metal rules in Fusion 360. 1. Navigate to the Sheet Metal tab, click MODIFY, and then click Sheet Metal Rules. This will open the Sheet Metal Rules window. 2. Hover over any existing rule to reveal the New Rule icon. Click the . Fusion 360 Sheet Metal - Flat Pattern is limited to Planar geometry with Cylindrical or Conical bends. No warped/twisted faces, even if they are developable. Part of the reason is the function calculates Bend Allowance. A sheet of metal compresses on the inside of a bend and stretches on the outside of the bend.

Learn how to design basic sheet metal goods in Autodesk Fusion. We'll discuss using the Flange tool, creating and updating Flat Patterns, sheet metal compone.I am pretty new to Fusion 360 so apologies if the way that I describe my problem isn't completely accurate. . doesn't-handle-double-curved-surfaces limitation, I extruded the profile of the body instead of revolving, to it's just curved in one plane. . Refold the sheet metal, and you've got an emboss on a body curved twice over. Note that I .

Multiple sheet metal bodies exist, but it is desired to have a single flat pattern for all the bodies. To combine sheet metal body and unfold, do the following: Create a bend using SHEET METAL > CREATE > FLANGE. Combine the Bodies using SOLID > MODIFY > COMBINE. Unfold the sheet metal using SHEET > MODIFY > UNFOLD. If sheet metal bodies . I can understand that you're disappointed that Fusion 360 can't bend bodies. But that was part of the answer. I don't think that showing an alternativ solution is a bad thing. Your part isn't that complex and it's easy to recreate. Unless you haven't stated that you know the trick with the sheet metal workspace, I did find it relevant to mention.

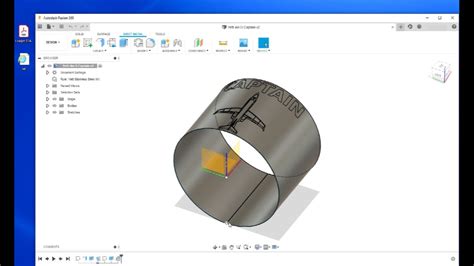

Fusion 360 Using Sheet metal FLANGE to create the cylinder, MODIFY-UNFOLD it so I can place designs on it and then Refold it So I can Send it to Sprutcam for.

Ok a lot of people have been asking how to do this so I will post all steps needed to make sheet metal wraps. . Have a tricky question about a Fusion (formerly Fusion 360) feature? Share your project, tips and tricks, ask questions, and get advice from the community. . Adding rivets to a curved surface: Phil Procario Jr. Owner, Laser & CNC .Learn Fusion 360 Sheet Metal in 20 minutes, with this crash-course for beginners. Thanks to our wonderful friends at SendCutSend.com for providing FAST and a.Learn how to convert a body or component to sheet metal body in Fusion. Design > Sheet Metal > Create > Convert to Sheet Metal. Convert a body to Sheet Metal created in Fusion. Make sure the body is in parametric modeling environment (the Timeline is displayed). Click on the Sheet Metal tab to activate the Sheet Metal environment. Creating a cone in sheet metal, which can be flattened for a pattern, is something you'll need to know a trick or two to do. Why? Well - Fusion 360's math as.

acra amc 1600p cnc mill machine

The oven conduit will come down through a hole in the cabinet's oven floor and enter the junction box from the top, as the box is oriented in this picture. I think the simplest way to get the 6-3 source cable into the junction box is to bring it in through the back of the box as it will be oriented, which is actually the bottom of the junction .

fusion 360 curved sheet metal|fusion 360 sheet metal thickness