sheet metal flat pattern layout Mathematically k factor value is equal to the ratio of position of the neutral axis and . Vehicle chassis comes in four different types: backbone, ladder frame, monocoque, and tubular. The backbone chassis offers excellent support for off-road driving in mind. It has a rectangular cross-section tube that connects the front and rear suspension. The tube also surrounds the driveshaft.

0 · solidworks sheet metal flat pattern

1 · solidworks no flat pattern configuration

2 · sheet metal flat pattern calculator

3 · sheet metal flat length calculation

4 · sheet metal flat layout calculator

5 · sheet metal calculator layout

6 · flat pattern layout calculator

7 · blank size calculator sheet metal

It definitely says max 6mm (221-613) but if they are not suitable will have to order some 773's on line. A 60amp junction box isn't suitable as it needs to be maintenance free.

Sheet Metal flat pattern calculator can be used to calculate sheet metal flat length as per required sheet metal bend part.K Factor in sheet metal bending is a constant used to calculate sheet metal .

Mathematically k factor value is equal to the ratio of position of the neutral axis and . Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It .In Sheet Metal or Fabrication Industry Flat Pattern making is useful for forming various shapes such as Conical Shapes, Box Shapes, Pipe Shapes, Transition Shapes such as Square to .

Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss sheetmetal bend deduction, bend allowance, K . This webinar focused on all the tips you need to know to work with sheet metal flat patterns in Onshape. Topics covered included creating features in the sheet metal flat pattern, exporting to DXF/DWG, and more.

Accurate Flat Pattern Layout: Inside Setback ensures that the flat pattern is dimensioned correctly, allowing for precise bending and resulting in a part that matches the desired final dimensions.

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .Before a sheet metal part is formed, make a flat pattern to show how much material is required in the bend areas, at what point the sheet must be inserted into the forming tool, or where bend lines are located. Bend lines must be .

solidworks sheet metal flat pattern

my bathroom vanity light has no junction box

Creating Drawings of Flat Patterns. To create a drawing of a flat pattern: Open the sheet metal part for which you want to add a drawing. Click Make Drawing from Part/Assembly (Standard .Sheet metal flat patterns. Use the Flat Pattern tool to create a flat pattern that you can use to create drawings of a sheet metal component for manufacturing in Fusion. A Flat Pattern is the shape of the sheet metal component before it is .

Layout Drafting & Pattern Making for Insulators Page 2 Preface This book has been prepared as a text for use in Heat and Frost Insulator apprenticeship classes. It explains basic methods of drawing patterns for developing sheet metal and other types of protective covers commonly produced for wrap over insulation. The book does not attempt to teachPattern book (English) 20+ Patterns; Sheet metal and band cut charts; Insulation miter cut charts; 90°& 45° prefabed size charts; Letter charts for insulation corresponding to the WH Ruler.Aware of the difficulties encountered by sheet metalwork companies to perform their sheet metal flattening layout – an operation which consists in defining the “patterns” of parts made from sheet metal – he decided to create a tool to .

When your design contains components, you can create a drawing that contains flat pattern and a folded design in the same sheet, using the Create Drawing tool accessible from the right-click menu from the activated component. Tips. You can create one flat pattern per sheet metal body. Flat patterns do not support all the distributed designs . Several terms are at the heart of any sheet metal bending operation, including the neutral axis, inside bend radius, outside setback (OSSB), and bend allowance (BA). You calculate the bend deduction by doubling the OSSB and subtracting the BA. . You can apply all this in two different ways to your flat pattern layout. One way subtracts the BD .

my time at portia wiki metal box

Hey, I have an issue with flat layouts, when a draw a round object such as a rolled punched plate it would be nice to have the flat layout show what the hole callout and spacing would be, however with the way i draw the model. the holes come out as an ellipse, attached is a document showing how i drew the model. Any help is appreciated, Thanks.K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss sheetmetal bend deduction, bend allowance, K-factor, Y-factor, and sheet metal flat pattern calculations. The second flat-blank-development example adds the two dimensions (from edge to the apex), and subtracts a bend deduction. In this case, the calculations use a complementary angle for the OSSB, and the dimensions are called from the edge to the apex—again, as specified in Figure 4.. Outside Setback (OSSB) Accurate Flat Pattern Layout: Inside Setback ensures that the flat pattern is dimensioned correctly, allowing for precise bending and resulting in a part that matches the desired final dimensions. Proper Fit and Assembly: Accurately calculating Inside Setback ensures that bent parts fit together correctly during assembly, avoiding issues that .

Sheet Metal Pattern Layouts. by Edwin Anderson | Jan 1, 1943. 4.7 out of 5 stars. 5. Hardcover. . with practical and modern methods for laying out and forming patterns for round and . formulas applies to sheet-metal work. by Joseph J Kaberlein | Jan 1, 1947. 4.8 out of 5 stars. 6. Hardcover. . Practical Sheet Metal Layout: Fittings Used .Cone Height is the Distance between the Large end and small end vertically. it is required for the cone fabrication layout or flat Pattern layout development. It is denoted by H. Refer Standard Image for Cone Height H. Cone Angle (α) : Cone Angle is included half-angle of the cone. It is denoted by α. Cone angle should be entered in Degrees.

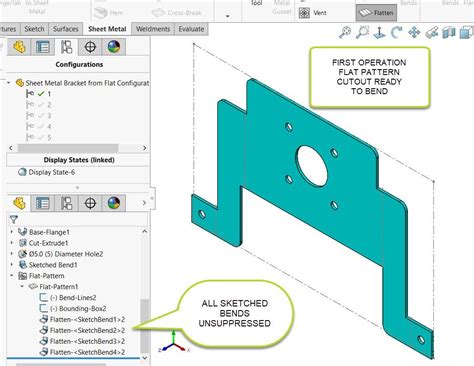

Create drawings for production using a flat pattern, which is the shape of the sheet metal part before it is manufactured. Flat patterns depict bend lines, bend zones, punch locations, and the overall contour of a part with all bends flattened and bend variables taken into account.Sheet Metal Pattern Layouts Bookreader Item Preview . Layout dc.subject.keywords: Shape dc.title: Sheet Metal Pattern Layouts. Addeddate 2017-01-17 20:55:49 Identifier in.ernet.dli.2015.16712 Identifier-ark ark:/13960/t67429681 Ocr ABBYY FineReader 11.0 .The Flat-Pattern1 feature is intended to be the last feature in the folded sheet metal part. All features before Flat-Pattern1 in the FeatureManager design tree appear in both the folded and flattened sheet metal part. All features after Flat-Pattern1 appear only in the flattened sheet metal part.. Improvements to flattening sheet metal parts make flattening succeed for complex .

To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: (Outside Diameter – Thickness) x 3.1416 = Length of Plate Required (Inside Diameter + .Get here more information on Sheet Metal Layout Software by CADCIM Technologies,Read Download Instruction Manual & Download demo programs, you can Buy Sheet Metal Layout Software from our website . Written in .Review this sheet metal layout tip on why you should not dimension in the flat pattern and instead always dimension to the formed view for your manufacturer . This is a common occurrence when manufacturers receive a sheet metal .When your design contains components, you can create a drawing that contains flat pattern and a folded design in the same sheet, using the Create Drawing tool accessible from the right-click menu from the activated component. Tips. You can create one flat pattern per sheet metal body. Flat patterns do not support all the distributed designs .

Hi, I have an assembly of about 10 folded sheet metal parts. I would like to lay them all out in a single flat pattern for waterjet cutting, but maintain a connection to the originals so I can keep working on the design. I tried another forum suggestion of making copies of my parts within another component (and arranging them appropriately) but it the folds defeat me. .

How to make Flat Pattern or Fabrication Layout for Sheet Metal Works or Fabrication Shapes. Flat Pattern is nothing but unfolded shape of any sheet metal shapes or fabrication shapes before forming processes such as Bending, Rolling, etc. We .

Sheet Metal Bending; Stainless Steel Bending; Calculators. Radius Calculator; . Flat Pattern Outside Radius: inches Flat Pattern Degrees: degrees Gross Rectangle Width (per pc) inches Gross Rectangle Length (per pc) . Design Guide; Blog;

In a sheet metal part, create a new configuration. In the FeatureManager design tree, do one of the following: Right-click Flat-Pattern and select Unsuppress.; Select Process-Bends and all of the features after it. Click Edit > Suppress > This Configuration to .One of the biggest benefits of Onshape’s Simultaneous Sheet Metal features is the ability to see the flat pattern update in real time as you make changes to your sheet metal part. But what about creating drawings of that flat pattern? Let’s take a look. Inserting flat patterns into drawing views in Onshape is very simple.

Computer-Aided Design A place to talk about anything related to CAD. Ask questions about CAD software, drawing standards or just show off your latest project. . i worked at a large company with a world-class sheet metal manufacturing plant attached. we were required to provide a flat pattern view with each sheet metal drawing, but dimensions . Whenever you modify a sheet metal design in the flat pattern, e.g. by rounding or drilling holes, all those features do not show up in the normal model view, which I would expect. I think other CAD programs do that and it would make most sense. Solved: Whenever you modify a sheet metal design in the flat pattern, e.g. by rounding or drilling .In the Browser, click the Activate Flat Pattern radio button. In the Create Drawing dialog, set the Destination options, and click OK. Create drawing view that contains the folded sheet metal body and the flat pattern. In the Create Drawing dialog, select Flat .

Pipe Insulation & Metal Layout Handbook (English Version) .00. Buy. Buckaroos Insulator’s Handbook (English Version) .00. Buy. English Pattern Book (8.5"X5.5") HARDCOVER. . Since 2011 FLAT METAL PATTERNS has been observing the insolation industry community. On January 19, 2016 we decided to undertake this project as we saw the need to .

solidworks no flat pattern configuration

murphy cabinet cabinet steel vintahe

Here’s the deal: For a #10 screw, your go-to drill bit size is going to differ based on the type of wood you’re working with. A 3/32” bit is your best bet if you’re cozying up to softwood. But if you’re dealing with the tougher stuff, like hardwood, you’ll want to step it up a notch.

sheet metal flat pattern layout|sheet metal flat pattern calculator