class 1 div 2 junction box requirements I can't find where the code lists acceptable juction boxes for a Class 1 Div 2 area. Per 501.10(B)(4) Boxes and Fittings "Boxes and fittings shall not be required to be . CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like .

0 · nema class 1 div 2

1 · hubbell explosion proof junction box

2 · explosion proof junction boxes catalog

3 · explosion proof junction box specification

4 · crouse hinds junction box catalogue

5 · class 1 div 2 enclosure

6 · 1x22 explosion proof j box

7 · 12x12 explosion proof junction box

There are seven main types of CNC machines: milling machines, lathes, routers, plasma cutters, laser cutting machines, drilling machines, and grinding machines. CNC technology combines computer control with traditional machining processes, resulting in high precision, efficiency, and automation.

nema class 1 div 2

customized distribution box

hubbell explosion proof junction box

Junction boxes listed can be furnished with drilled and tapped openings, subject to material required and the limitations of maximum size and number of openings as well as spacing, as . Junction boxes in a Class 1 Division 2 area that contain only splices and not equipment can be NEMA 1 or whatever you need for the environment that is in the area. There .Class 1 Div. II Enclosure System and its antennas are to be installed; it must be controlled in accordance with IEC 60079- 0, and must not exceed the following levels: IIC – 2W (+33dBm) .

I can't find where the code lists acceptable juction boxes for a Class 1 Div 2 area. Per 501.10(B)(4) Boxes and Fittings "Boxes and fittings shall not be required to be . For indoor use in Class II, Division 1, Groups E, F, and G hazardous locations according to NFPA 70, this is also referred to as dust-ignition proof. These enclosures are intended to meet the Mine Safety and Health .Crouse-Hinds series EJB explosionproof enclosures are designed for hazardous locations to be used as a junction or pull box, to provide enclosures for slices and taps, and for housing .

Junction boxes listed can be furnished with drilled and tapped conduit openings, subject to the limitations of maximum opening, number and spacing shown in Tables 1, 2 and 4. Select the .Fixed general-purpose equipment in Class I locations, other than lighting fixtures, which is acceptable for use in Class I, Division 2 locations need not be marked with the class, group, .

customized aluminum sheet metal box factories

CSA routinely marks material/equipment for Division 2 even where the CEC (oddly enough a CSA document) doesn't require it. In the US, unless the installation required an . Re: Class I Div 2 junction boxes Junction boxes in a Class 1 Division 2 area that contain only splices and not equipment can be NEMA 1 or whatever you need for the environment that is in the area. There is no requirement that the wiring in the box be IS or non-incendive type circuits. 120, 480 or even 5kV could be spliced on open terminals in a . Re: Junction box w/terminals blocks class 1 div 1 See 501.15 (A). If the box has arcing/sparking devices within it, or has conduits larger than 2" entering it, then seals are required. The box is required to be approved for Cl 1 Div 1 per 501.10 (A)(3). When it comes to installing a junction box on a piece of equipment within a CIID2 area, NEMA 4X rated. Which will be used to house only DIN mounted terminal blocks so that there are connection points from the devices on the machine, which would be intrinsically rated sensors and CIID2 rated AC.

My comment "I don't believe that you can use NEMA 4X enclosures in a Div 1 area." is wrt what I believe that a motor OEM will normally provide on a motor designated for Class-1 Div-1 rating. ie I have never seen a motor OEM supply anything other than cast explosion-proof boxes on such a motor. Excuse my Article 500 ignorance, but I need a sanity check. I can't find where the code lists acceptable juction boxes for a Class 1 Div 2 area. Per 501.10(B)(4) Boxes and Fittings "Boxes and fittings shall not be required to be explosionproof except as required by 501.105(B)(1), 501.115(B)(1) and 501.150(B)(1) My situation: I have a septage receiving building previously classified as class 1 div 2. Recently it went under construction, some new equipment was installed and re-classified as Class 1 Div 1. Some of the old equipment (lighting and heat trace are rated C1D2,) and a Stainless steel Nema 4x junction box are still in the room.

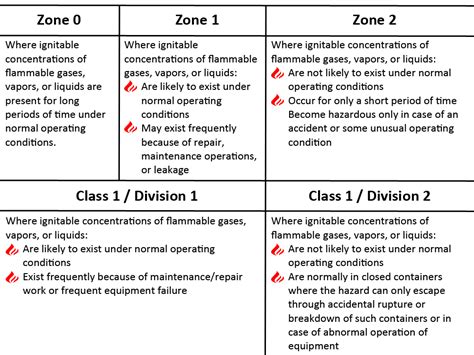

A Div. 2 exists in a Class I location only under the following three conditions [500.5(B)(2)]: The liquids, vapors, or gases are confined within closed containers or systems. Positive mechanical ventilation prevents “critical mass” accumulation. Positive mechanical ventilation prevents spillover from an adjacent Class I, Div. 1 location.

For Div 1 Boundary (501.15(A)(4) contains the same language for Div 2 with a couple of additional exceptions which do not apply in this case. So Augie47 if you are saying that you can indeed install a j-box between the boundary and the seal we would be in disagreement.

You responded "not in Div 2" to my question about seal off's for j-boxes that are just for makeup. If this is in fact a div. 1 location would the seal off's be required at that point? In section 501.5 (A)(1)(1) it doesn't mention taps or splices in a division 1 location either. Am I reading this correctly? Thanks for the earlier prompt response.

In the NFPA 70 handbook (2014) it has a note under 501.10 (B) (4) that says 'In Class 1, Division 2 locations, boxes, fittings, and joints are not required to be explosionproof if they contain no arcing devices; or for lighting outlets or enclosures containing non-arcing devices, if the maximum operating temperature of any exposed surface does .

Re: Class I Div 2 junction boxes Junction boxes in a Class 1 Division 2 area that contain only splices and not equipment can be NEMA 1 or whatever you need for the environment that is in the area. There is no requirement that the wiring in the box be IS or non-incendive type circuits. 120, 480 or even 5kV could be spliced on open terminals in a . Re: Junction box w/terminals blocks class 1 div 1 See 501.15 (A). If the box has arcing/sparking devices within it, or has conduits larger than 2" entering it, then seals are required. The box is required to be approved for Cl 1 Div 1 per 501.10 (A)(3). When it comes to installing a junction box on a piece of equipment within a CIID2 area, NEMA 4X rated. Which will be used to house only DIN mounted terminal blocks so that there are connection points from the devices on the machine, which would be intrinsically rated sensors and CIID2 rated AC. My comment "I don't believe that you can use NEMA 4X enclosures in a Div 1 area." is wrt what I believe that a motor OEM will normally provide on a motor designated for Class-1 Div-1 rating. ie I have never seen a motor OEM supply anything other than cast explosion-proof boxes on such a motor.

Excuse my Article 500 ignorance, but I need a sanity check. I can't find where the code lists acceptable juction boxes for a Class 1 Div 2 area. Per 501.10(B)(4) Boxes and Fittings "Boxes and fittings shall not be required to be explosionproof except as required by 501.105(B)(1), 501.115(B)(1) and 501.150(B)(1)

My situation: I have a septage receiving building previously classified as class 1 div 2. Recently it went under construction, some new equipment was installed and re-classified as Class 1 Div 1. Some of the old equipment (lighting and heat trace are rated C1D2,) and a Stainless steel Nema 4x junction box are still in the room. A Div. 2 exists in a Class I location only under the following three conditions [500.5(B)(2)]: The liquids, vapors, or gases are confined within closed containers or systems. Positive mechanical ventilation prevents “critical mass” accumulation. Positive mechanical ventilation prevents spillover from an adjacent Class I, Div. 1 location. For Div 1 Boundary (501.15(A)(4) contains the same language for Div 2 with a couple of additional exceptions which do not apply in this case. So Augie47 if you are saying that you can indeed install a j-box between the boundary and the seal we would be in disagreement.

You responded "not in Div 2" to my question about seal off's for j-boxes that are just for makeup. If this is in fact a div. 1 location would the seal off's be required at that point? In section 501.5 (A)(1)(1) it doesn't mention taps or splices in a division 1 location either. Am I reading this correctly? Thanks for the earlier prompt response.

What is CNC programming? Discover how it shapes modern manufacturing, and why it's crucial for creating precise components in this guide by JetCrafted.

class 1 div 2 junction box requirements|1x22 explosion proof j box