how torough in electrical outlet boxes When installing an electrical outlet outdoors, the box must be at least 6 1/2 inches above grade, and in garages, they should be 18 inches or more above the floor, as measured from the center of each box.

$312.25

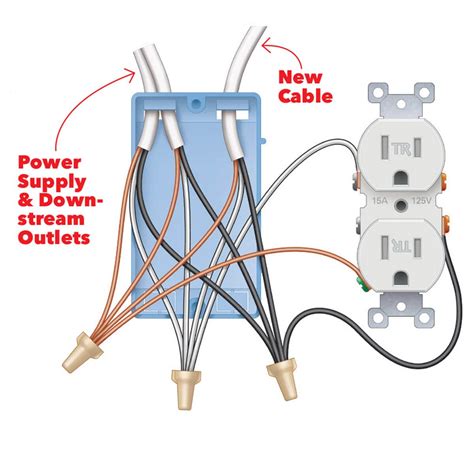

0 · wiring additional outlet

1 · properly wiring an outlet

2 · installing wall outlet box

3 · installing outlet in existing wall

4 · installing a new outlet box

5 · how to install residential outlet

6 · how to install outlet box

7 · 6 wires for new outlet

The PIK consists of a Varian- provided Main Disconnect Panel and Relay Junction Box (MDP and RJB ). These components are typically ordered and shipped to site by the Varian PM for the cust omer to install prior to the Halcyondelivery. The Varian supplied components must be installed in accordance with -

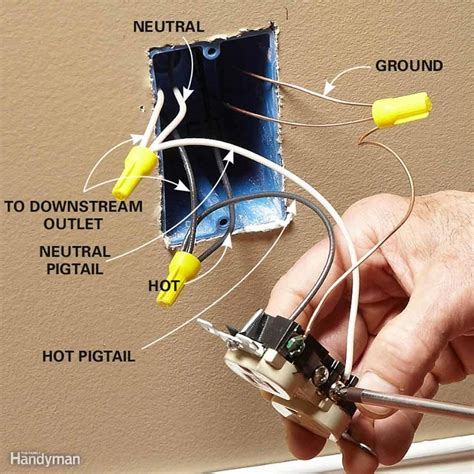

How To Rough In Electrical For Receptacle Outlets & Switches. Rough in wiring with 12/2 wire.🟡 Check out my Amazon store! 👉 https://www.amazon.com/shop/the. Here I explain the process of how you rough in a standard outlet in a daisy chain using pigtails. It is important to roll the wires in neatly and in the order of grounds, neutrals, and finally. This is a quick tutorial for all those electrical diy guys out there. This one will demonstrate how to properly rough in a receptacle box on wood studs. To clarify, roughing in as an electrician refers to pulling wring, drilling holes, mounting box heights for receptacles and light switches, or bending emt pipe, building pipe racks, building an electrical room, or even looking at .

Electrician Brian Walo shows an easy way to strip non-metallic cable plus a great way to keep track of which wires do what. Watch this video to learn wire-stripping tips for roughing an .

When installing an electrical outlet outdoors, the box must be at least 6 1/2 inches above grade, and in garages, they should be 18 inches or more above the floor, as measured from the center of each box.Cable connectors (also called clamps) solidly connect cable to the box to prevent strain on electrical connections inside the box D. Cable clamps also prevent sheathing from being scraped or punctured by sharp box edges. Plastic boxes .Walk the room with plans, marking outlet locations on walls and floor. Snap chalklines or shoot laser lines to pinpoint box elevations. Attach boxes to studs and ceiling joists. Drill holes for cable runs. Pull cable through holes and into .

Episode 3: Installing Boxes – The Right Box in the Right Place In this episode, Cliff starts the rough-in process by first discussing the major types of electrical boxes, always handy info to have when you’re trying to choose a box from the .

Wire Strippers https://amzn.to/3e6jq2UIn this video I will show you how to install rough in electricity in a new construction house. This is how to do wire a. Thanks for the advice everyone! Yes, I, just got boxes like these from my local electrical supply place. Actually I first got some tan Allied "Slider Boxes" from there, which I thought would work great because they are .Grasp the loose sheathing in one hand and snip the loose sheathing with the jaw of the cutters, about 1/2-in. from where the wire comes into the electrical box. This way you will keep the 1/4-in. minimum of sheathing protecting the wires where they contact the potentially sharp edges of the box. More on Electrical Old work boxes are designed for use when installing new electrical wiring in walls that already have a finish applied. Using old work boxes eliminates the need for access to the furring strips because they are held in place by mounting wings that swing out and draw up against the back of the wall finish.

The standard height for wall outlet boxes is about 12 inches from the top of the floor covering to the bottom of the receptacle box (or 16 inches to the top of the box). If you are setting box heights prior to the installation of the subfloor , floor covering, or any underlayment , be sure to account for this expected height difference. I wanted to do the project the correct way so I pulled the permits to add electrical outlets by tapping off the existing outlets. Also I am adding one new home run to the circuit breaker panel for a dedicated microwave above the stove. . Your inspector will be looking at box fills, cable runs for stapling and clearance through framing, or . Electrical Boxes: These house switches, outlets, and other electrical devices. Cable Clamps: To secure wires to boxes. Wire Nuts: For securely joining wire ends together. With the rectangular device boxes you will have to use separate fixture straps to match the screw holes on the box to the differently spaced holes on the Luminaire's base. The long slots go on the screws of the rectangular device box and the cross strap has both several threaded holes and the slots to support the luminaire.

happy memorial Day to you all. For those veterans out there, thank you for your service to our country ️ This 1400 square foot home wired on 2017 N.E.C. code.

wiring additional outlet

properly wiring an outlet

Electrical box inside the air control layer on an exterior wall An airtight box installed on the exterior of the air control layer. As noted, we were using airtight electrical boxes back in the late 1990s, but I still see errors in these requirements today. Below is a photo from a recent code-compliant blower-door test. The home passed, but I .

Punch out the holes you need for electrical cables, if the box is metal. Insert the box into the hole and tap it in until the front edge is flush with the wall. Go inside the house and cut a rectangular hole into the drywall directly behind the box, using a drywall saw. This ensures you can fasten the outlet box to a stud.

However, leaving 6-8 inches of wire length is the most flexible option if you use an outlet box with a higher depth. Leave 8 inches for an outlet box that has 4 inches of depth. Be mindful of: When using metal outlet boxes, remember to ground the outlet box. Use an insulated green wire or a bare copper wire for this.

The installation of vapour barrier around electrical outlet boxes is not an electrical code requirement; it is a requirement of the Ontario Building Code that is enforced by your municipal building inspection department. Reference is .

I've used the "old work" boxes with drywall clips and ears to put in a switch or outlet (so you can mount them vertical or horizontal as needed), but when my house was roughed in all of the 1 gang outlets are horizontal. What . My house plan calls for installing the electrical outlets horizontally in the 7 1/4" baseboard. Looks like it would be a nice effect. How would you accompish this from both the gang box perspective (to meet code) and from the trim installation perspective. . Long screws with recessed boxes = loose outlets and a failed inspection. The last . It takes some extra time, but I carefully measure and locate trim blocks on the sidewall for outlets, lights and hose bibs. The blocks fall in one course of siding or two depending on the exposure. . If the inspector requires the boxes to be mounted to pass rough electrical, OK. Tell the Sparkie you want enough cable slack to move the box .I have 2 question on electrical rough-in. 1) For the outlet boxes, do I strip and wire nut the wires or just roll them up and tuck them in for the inspection? 2) For my recessed canless LED lights (see picture below). Can I mount and wire the the j-boxes (driver boxes) for the rough in inspection?

Rugg, Edward H. Outlet box arrangement for electrical wiring systems [PDF] U.S. Patent 2,374,622, issued April 24, 1945. Excerpt: The outlet box' arrangement shown in the drawing comprises a box l made of non-metallic material such as a ceramic or plastic material having front and rear walls ll and side walls It. 48 or 46 to center to top screw hole for switches and counter outlets with a laser going around to check for level Outlets are 17 3/4 to top or MY HAMMER no one else's under the box height. Bath sconces on either side of mirror are usually 5 ft center but depends if there's an elevation drawing.

The definition of an electrical home run is: “.a wiring run that is not branched from another circuit or wiring run, but that connects directly to the building’s main electrical panel.” In essence, this is the starting point for understanding what it will take to rough in your basement electrical.Many boxes will actually have a pre-formed 1/2" reference line for quick installation.-Receptacles are commonly mounted 16" high from floor to center of electrical box. Some folks prefer 12" heights rather than 16".-Mounting heights for light switches are typically 42" to 48" from floor to center of electrical box. Welcome to my guide on how to rough in for electrician’s. To clarify, roughing in as an electrician refers to pulling wring, drilling holes, mounting box heights for receptacles and light switches, or bending emt pipe, building pipe racks, building an electrical room, or even looking at electrical prints and understanding panel and equipment schedules.

Rough in electrical - outlet courtesy loop. . that when the drywaller comes along and uses his roto-zip with the blade all the way out and cuts our wires inside the box, we still have wire to rectify this. Depending on the item being wired, sometimes we will leave more than 12", but this gets complicated quickly because the cable needs to be . If they actually work 2 x8 hour days then I would say that is realistic.If these are code minimum homes then the process is much easier.Two good men should be able to rough in approx. 130 outlets in a day.That includes making up the boxes as well..The 130 outlets is . Wire Stripper Tool I Use: https://amzn.to/2yQMWV9When pulling wire into an electrical box it is important to leave yourself plenty of wire but not too much e.

Re: Electrical Boxes in block walls Steve typing mistake 1.5" is the correct choice 1/8 and 1/4 plaster rings are incorrect per Article 314.20 which states In wall or ceilings with surface of concrete, tile, gypsum, plaster or other noncombustable material, boxes shall be installed so that the front edge will not be set back of the finished surface more than 6 mm (1/4)

installing wall outlet box

installing outlet in existing wall

To calculate tool rotations n we need to know the cutting speed Vc, in other words the number of rotations of the cutting blade, given in meters per minute. Too slow cutting speeds lead to edge build-up and blunting, while too fast results in quicker insert wear, deformation and poor finish.

how torough in electrical outlet boxes|6 wires for new outlet