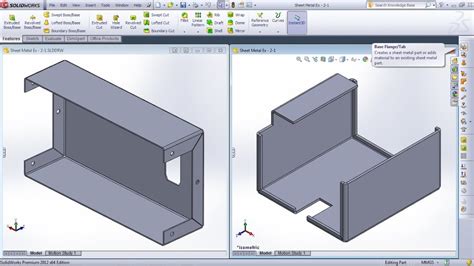

flatten complex sheet metal parts solidworks To create a flat pattern configuration: In a sheet metal part, create a new . U-shaped brackets are support fittings for piping and the general term for U-bolts and U-bands. They are also known as anti-vibration brackets. They are used when fastening a pipe or square bar to a wall, floor or the ground.

0 · SolidPractices: Sheet Metal

1 · SOLIDWORKS Lofted Bends for Complex Sheet

2 · Rolled Sheet Metal Part: How to Prepare It in

3 · How to Flatten a “dumb” solid in SOLIDWORKS

4 · How To Model Complex Sheet Metal Parts in

5 · Flattening Sheet Metal Bodies

6 · Flattening Sheet Metal Bends

7 · Flat Pattern

8 · Creating Sheet Metal Flat Pattern Configurations

Explore various types of electrical connectors for diverse wiring needs. Learn about compression, MC, liquid tight, split bolt connectors and more.

SolidPractices: Sheet Metal

To flatten a body, do one: In the FeatureManager design tree, select the part and click Flatten (Sheet Metal toolbar). In the cut list, right-click the body and click Flatten . In either the .The Flat-Pattern1 feature is intended to be the last feature in the folded sheet metal .To create a flat pattern configuration: In a sheet metal part, create a new .The bend lines are shown by default when you unsuppress Flat-Pattern1. To hide .

The following example demonstrates the steps necessary to calculate the flatten .The Flat-Pattern1 feature is intended to be the last feature in the folded sheet metal part. All features before Flat-Pattern1 in the FeatureManager design tree appear in both the folded and .To create a flat pattern configuration: In a sheet metal part, create a new configuration. In the FeatureManager design tree, do one of the following: Right-click Flat-Pattern and select .

The article has a detailed example of how we can build a model and then use the edges of that part to create the profiles needed to create a Lofted Bend in sheet metal and ultimately be able to flatten the part for .You can individually flatten any body in a multibody sheet metal part. To increase performance when flattening sheet metal bodies with a large number of patterns, click Tools > Options > . In this tech tip learn how to flatten a dumb solid in SOLIDWORKS to obtain a flat pattern from an imported .STEP or .IGES sheet metal part file.The bend lines are shown by default when you unsuppress Flat-Pattern1. To hide the bend lines, expand Flat-Pattern1, right-click Bend-Lines, and select Hide. When you flatten the entire part .

The following example demonstrates the steps necessary to calculate the flatten length by using a bend deduction. Figure 19c. The image on the left side of Figure 19c shows a simple sheet . How To Model Complex Sheet Metal Parts in SOLIDWORKS. A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat . One of the best ways to leverage the power of a 3D CAD software like Solidworks for laser cut parts is to utilize a feature known as “flatten.” This trick works for bends, jogs, and rolled parts and allows you to design the .

Most sheet metal features can only be added to a single body at a time. You can cut holes through multiple bodies with a single feature; How to flatten multibody parts. The default Flatten icon is not sufficient for getting an .Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .

SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create complex sheet metal designs. Multibody sheet metal parts can consist of multiple sheet metal bodies or a combination of sheet metal and other bodies such as weldment bodies. Each body has its own sheet metal and material definition, flat pattern, and .

If you use a feature to create additional bodies in a sheet metal part, each new body gets a sheet metal and flat pattern feature. This option applies to parts created prior to SOLIDWORKS 2013. Otherwise, each body in a multibody sheet metal part has its own flat pattern.

If you use a feature to create additional bodies in a sheet metal part, each new body gets a sheet metal and flat pattern feature. This option applies to parts created prior to SOLIDWORKS 2013. Otherwise, each body in a multibody sheet metal part has its own flat pattern.

8) Designing Sheet Metal From the Flat When designing sheet metal parts from the flat, it is important that every feature you create have the proper reliefs, and that these reliefs belong to the feature you create. You must either create the bend reliefs before the bend operation (that is, create the feature), or create the reliefs with the .SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create complex sheet metal designs. Multibody sheet metal parts can consist of multiple sheet metal bodies or a combination of sheet metal and other bodies such as weldment bodies. Each body has its own sheet metal and material definition, flat pattern, and .When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing.The Flat-Pattern1 feature is intended to be the last feature in the folded sheet metal part. All features before Flat-Pattern1 in the FeatureManager design tree appear in both the folded and flattened sheet metal part. All features after Flat-Pattern1 appear only in the flattened sheet metal part.. Improvements to flattening sheet metal parts make flattening succeed for complex .

When it comes to sheet metal parts, you want to avoid a flat sheet metal part and adding bends is usually the go-to method for sheet metal designers as they begin their design. A lot of the time damage is sustained on the outer edges of a sheet metal part so having bends or folds on the outer edges adds more rigidity to the part, so it doesn .

SOLIDWORKS Lofted Bends for Complex Sheet

You may need to use ‘surface flatten’ which is in professional or premium, (which ever one costs more) and is not in standard. I’ve used a demo of it but don’t have it. Sheet metal as far as I can tell works well if you’re going to bend a straight edge, but .Multibody Sheet Metal Parts: Using Sheet Metal Bend Parameters: Simulation: SimulationXpress: Sketching: . When you flatten a sheet metal part by unsuppressing the Flat-Pattern feature, corner treatments are automatically applied to create a clean, flattened sheet metal part. The corner treatments are applied so the flat pattern is correct .

The Flat-Pattern1 feature is intended to be the last feature in the folded sheet metal part. All features before Flat-Pattern1 in the FeatureManager design tree appear in both the folded and flattened sheet metal part. All features after Flat-Pattern1 appear only in the flattened sheet metal part.. Improvements to flattening sheet metal parts make flattening succeed for complex .If you have SOLIDWORKS Premium you can use the Surface Fatten tool (GoEngineer - SOLIDWORKS - Surface Flatten). However, this tool will not account for material stretching of sheet metal so it will only make a "close but .It is too complex for solidworks "sheetmetal" analysis, and fairly difficult to figure out on paper. . Does anyone know an add on or separate program i can use to flatten this out and see the exact shape? Thank you! Reply reply . i've had . In the mirrored part I converted to sheet metal so that I can derive a flat pattern. . But it does when you expand the feature tree in the drawing. This is not a particularly complex piece of sheet metal. It is, however, complex in its derivation. None of the bends are at 90° and it is created with references to several other parts of the .

I am currently a student working on developing my skills in sheet metal design and generating accurate flat patterns. I am having an issue creating a Sheet Metal Loft between two sketches and can't figure out why. (I have been able to model the piece as a solid body using splines however SW does not allow the use of splines in sheet metal parts.)To open this dialog box: With a part, assembly, or drawing open, click Tools > Options > Document Properties > Sheet Metal.. To show bend lines in flat patterns, do one of the following: Click View > Hide/Show > Sketches.; In the FeatureManager design tree, expand Flat-Pattern and Flat-Pattern(n).Right-click Bend-Lines and click Show.To open this dialog box: With a part, assembly, or drawing open, click Tools > Options > Document Properties > Sheet Metal.. To show bend lines in flat patterns, do one of the following: Click View > Hide/Show > Sketches.; In the FeatureManager design tree, expand Flat-Pattern and Flat-Pattern(n).Right-click Bend-Lines and click Show.

The Flat-Pattern1 feature is intended to be the last feature in the folded sheet metal part. All features before Flat-Pattern1 in the FeatureManager design tree appear in both the folded and flattened sheet metal part. All features after Flat-Pattern1 appear only in the flattened sheet metal part.. Improvements to flattening sheet metal parts make flattening succeed for complex . : Check override default parameters if you wish to adjust the thickness of your sheet metal part: Click the green tick. Now you have your basic profile in sheet metal form. Step 3: Unfold Your part: Select the unfold function in the command manager also in the the sheet metal tab: Select a flat surface for the part to begin to unfold fromThe Flat-Pattern1 feature is intended to be the last feature in the folded sheet metal part. All features before Flat-Pattern1 in the FeatureManager design tree appear in both the folded and flattened sheet metal part. All features after Flat-Pattern1 appear only in the flattened sheet metal part.. Improvements to flattening sheet metal parts make flattening succeed for complex .

Sheet Metal Part 1: This is a sheet metal part symmetric vertically with respect to the Right Plane. Sheet metal features are used so that the part can be flattened out to create a flat pattern. Sheet metal features determines the thickness, bend radius, and k factor. 14 Gauge Steel is used for this model.

SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create complex sheet metal designs. Multibody sheet metal parts can consist of multiple sheet metal bodies or a combination of sheet metal and other bodies such as weldment bodies. Each body has its own sheet metal and material definition, flat pattern, and .This is useful when working with developable surfaces such as sheet metal parts with non-standard bends. The SOLIDWORKS software can flatten developable and non-developable surfaces and faces. A developable surface is a surface that can be flattened onto a plane without distortion. Non-developable surfaces and faces deform when flattened.When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing.

china lunch box steel stainless

There are 5 main types: Austenitic Stainless Steel, Ferritic Stainless Steel, Martensitic Stainless Steel, Duplex Stainless Steel, and Precipitation-Hardening (PH) Stainless Steel. Each type has different compositions and properties suitable .

flatten complex sheet metal parts solidworks|Flattening Sheet Metal Bends