cnc lathe machine wikipedia The first CNC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the tool or part to follow points fed into the system on See more Buy No Stud TV Wall Mount, Drywall Studless TV Hanger No Damage, No Drill, Non Screws, Flat Screen Easy Install Bar Bracket fits VESA 12-55 inch TVs .

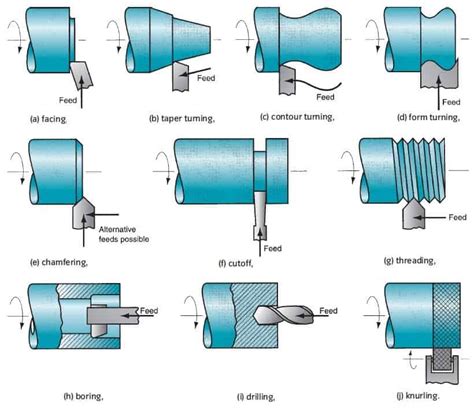

0 · types of lathe machine operations

1 · specification of lathe machine

2 · lathe machine with parts name

3 · lathe machine used for

4 · lathe machine simple diagram

5 · lathe machine parts and functions

6 · lathe machine meaning

7 · lathe machine explanation

$34.99

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. CNC transforms a piece of material (metal, plastic, wood, ceramic, stone, or composite) . See moreMotion is controlling multiple axes, normally at least two (X and Y), and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motors or servo motors to provide highly accurate . See more

The first CNC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the tool or part to follow points fed into the system on See moreMany other tools have CNC variants, including:• 3D printing• See moreWithin the numerical systems of CNC programming, the code generator can assume that the controlled mechanism is always perfectly . See moreNow the CNC in the processing manufacturing field has been very extensive, not only the traditional milling and turning, other machines and equipment are also installed with the corresponding CNC, which makes the manufacturing . See more

In CNC, a "crash" occurs when the machine moves in such a way that is harmful to the machine, tools, or parts being machined, . See more

In numerical control systems, the position of the tool is defined by a set of instructions called the part program. Positioning control is handled using either an open-loop or a closed-loop system. In an open-loop system, communication takes place in one . See more

A lathe may or may not have legs, which sit on the floor and elevate the lathe bed to a working height. A lathe may be small and sit on a workbench or table, not requiring a stand. Almost all lathes have a bed, which is almost always a horizontal beam, although CNC lathes commonly have an inclined or vertical beam for a bed t.The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the .CNC lathe machines are marvels of modern engineering, designed to perform CNC turning with incredible precision. But how do they work? At the heart of a CNC lathe machine is the .

A CNC lathe is a sophisticated machine tool designed for precision CNC turning and manufacturing through Computer Numerical Control (CNC). It’s an embodiment of technological evolution, marrying the age-old principles of a . A CNC lathe, or turning center, is a versatile tool used in various manufacturing processes. It consists of a spindle that rotates a workpiece and a tool block or turret to hold a cutting tool or stick-tool with a cutting insert.

What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far .

CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or .In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] . It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers.

Fully automatic mechanical lathes, employing cams and gear trains for controlled movement, are called screw machines. Lathes that are controlled by a computer are CNC lathes. Lathes with the spindle mounted in a vertical configuration, instead of horizontal configuration, are called vertical lathes or vertical boring machines.The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology.

CNC lathe machines are marvels of modern engineering, designed to perform CNC turning with incredible precision. But how do they work? At the heart of a CNC lathe machine is the concept of computer numerical control. This means the machine’s movements are directed by coded instructions, usually written in G-code. A CNC lathe is a sophisticated machine tool designed for precision CNC turning and manufacturing through Computer Numerical Control (CNC). It’s an embodiment of technological evolution, marrying the age-old principles of a lathe machine with advanced computer programming to achieve unprecedented accuracy and efficiency in machining.

types of lathe machine operations

A CNC lathe, or turning center, is a versatile tool used in various manufacturing processes. It consists of a spindle that rotates a workpiece and a tool block or turret to hold a cutting tool or stick-tool with a cutting insert. What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far more functionality than just this though.CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like . CNC lathes: CNC lathes are used to make cylindrical parts, such as gears, shafts, and pistons. They rotate the workpiece while the cutting tools remain stationary. They can have two or more axes and use different types of tools, such as drill bits, taps, and grinding wheels.

Computer numerical controlled (CNC) lathes are rapidly replacing the older production lathes (multispindle, etc.) due to their ease of set up, operation, repeatability and accuracy. A CNC Turning Lathe is a Computer Controlled piece of machinery.In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] . It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers.Fully automatic mechanical lathes, employing cams and gear trains for controlled movement, are called screw machines. Lathes that are controlled by a computer are CNC lathes. Lathes with the spindle mounted in a vertical configuration, instead of horizontal configuration, are called vertical lathes or vertical boring machines.The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology.

CNC lathe machines are marvels of modern engineering, designed to perform CNC turning with incredible precision. But how do they work? At the heart of a CNC lathe machine is the concept of computer numerical control. This means the machine’s movements are directed by coded instructions, usually written in G-code. A CNC lathe is a sophisticated machine tool designed for precision CNC turning and manufacturing through Computer Numerical Control (CNC). It’s an embodiment of technological evolution, marrying the age-old principles of a lathe machine with advanced computer programming to achieve unprecedented accuracy and efficiency in machining. A CNC lathe, or turning center, is a versatile tool used in various manufacturing processes. It consists of a spindle that rotates a workpiece and a tool block or turret to hold a cutting tool or stick-tool with a cutting insert.

metal brackets wood beams

What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far more functionality than just this though.CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like . CNC lathes: CNC lathes are used to make cylindrical parts, such as gears, shafts, and pistons. They rotate the workpiece while the cutting tools remain stationary. They can have two or more axes and use different types of tools, such as drill bits, taps, and grinding wheels.

metal buildings converted into houses

The Tulip® Dimensional Fabric Paint Metallic Starter Kit features 6 nontoxic glittery paints in popular colors that make clothes, backpacks, school projects and more shine with dimension. Create your own doodles, designs and more in METALLIC 3D effects.

cnc lathe machine wikipedia|specification of lathe machine