types of sheet metal drawing process Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to . Metals Depot - America's Metal Superstore is your complete supplier for industrial metals worldwide. Stocking over 50,000 Shapes, Sizes, Types and Lengths of Steel, Aluminum, .

0 · simple sheet metal drawings

1 · sheet metal forming drawing

2 · sheet metal diagram fabrication

3 · sheet metal deep drawing calculations

4 · sheet metal basic drawing

5 · metal spinning vs deep drawing

6 · metal sheet mechanical drawings

7 · deep drawing in sheet metal

Apeks Electric Co.,Ltd is one of the most professional distribution box manufacturers and suppliers in China. If you're going to wholesale bulk high quality distribution box at competitive price, welcome to get more information from our factory.

simple sheet metal drawings

junction box 意味

sheet metal forming drawing

This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. We’ll delve into its foundational principles, the technical aspects, and myriad benefits.This article will delve into the basics of deep draw sheet metal processes, the . The sheet metal drawing process typically involves several steps: Design: The design of the final part is created using CAD (Computer-Aided Design) software. Material Selection: The appropriate type and thickness of .

This article will delve into the basics of deep draw sheet metal processes, the importance of accurate sheet metal drawings, factors affecting deep drawing sheet metal success, tips for optimizing your metal drawing . Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to . These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming .

Metal drawing is utilised to produce wires used in electrical industries made from materials like copper and aluminium. Products like paper clips and helical springs are manufactured using the Metal drawing process. . Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .

junction boxes suppliers

Deep Drawing: A Spotlight On The Metal Forming Process. Types Of Deep Drawn. The Basic Principles Of Deep Drawing. Your Complete Guide To The Deep Drawing Process. Material checklist: Everything You Need To .A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points . Drawing Process; In the drawing aluminum process, one end of the aluminum stock is placed in a grip that holds it in place while the other is put through a die. This is called drawing, and the process involves pulling the . Stainless Steel Type 201/201L: This is an austenitic, non-magnetic, low-nickel stainless steel. It is generally used in draw forming sheet metal and deep draw stamping.Its lower nickel content makes it a more cost-effective .

The actual deep drawing process involves pushing a sheet of ductile metal (the blank) into a die by a punch, which forms it into the desired shape. The deep draw forming process can be repeated in a series of operations (re-draws) to create .#shorts #Bending_Process#Drawing_Process#Metal_Forming#Sheet_metal_cutting_operations#Manufacturing_ProcessesSubject - Manufacturing ProcessesChapter - Bendi. There are different types of hydroforming methods, such as tube hydroforming, bladder hydroforming, and sheet hydroforming, each with its own unique advantages and applications. Conventional Tube Hydroforming. . The image below shows the deep drawing process on a circular sheet-metal blank. The stripper ring facilitates the removal of the .

Sheet metal Drawing Operation involves drawing sheet metal parts in a cup-like shape by utilizing a bending press. This process is very extensively used in the automobile industry to achieve a high production rate.

Download scientific diagram | Deep drawing process and common failure types from publication: Sheet Metal Forming Using Additively Manufactured Polymer Tools | Due to various trends, such as e .

Successful drawing depends on the flow and stretch of the material. Steels, copper alloys, and aluminium alloys are commonly drawn metals. [4]In sheet metal drawing, as a die forms a shape from a flat sheet of metal (the "blank"), the material is forced to move and conform to the die. The flow of material is controlled through pressure applied to the blank and lubrication applied to .

The deep-drawing process often requires more than one drawing process. When more than one drawing process is used, the preceding drawing operations often are referred to as redrawing or reduction. The draw reduction process often is used to produce very deep geometry. Like a single drawing process, redrawing uses both metal flow and tension to .

Hi Friends,In this video you will learn Types of Drawing operations in sheet metal | Common Defects in drawing operationRedrawingReverse redrawingDefects in . The sheet metal drawing process, a key aspect of metalworking, is an art of transformation that has been perfected over centuries. It breathes life into mundane metal sheets, sculpting them into a myriad of shapes and forms to meet a plethora of requirements. From intricate automotive parts to everyday household items, sheet metal drawing is a crucial cog in . Various types of dies are used in sheet metal drawing, each designed to perform specific functions. Some of the common types include: Single-Operation Dies: . Comparison Table: Different Die-Making Methods for the Sheet Metal Drawing Process. As previously mentioned, sheet metal drawing dies can be manufactured through a variety of methods. .It’s very rare that an entire metal stamping project makes use of only one technique because each process achieves a certain design on sheet metal. Some types of metal stamping include the following: piercing, coining, lancing, drawing, embossing, and blanking.

In the deep drawing process, a flat sheet metal blank is placed over a die cavity, and a punch is used to press the blank into the die. . While hydraulic presses are ideal for deep drawing, other types of presses, such as mechanical presses and servo presses, may be more suitable for certain applications. Key differences include: .

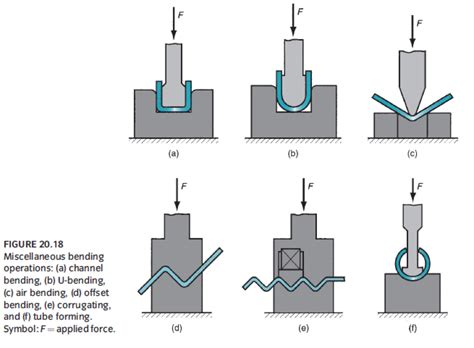

Unit 4-SHEET METAL PROCESSES - Download as a PDF or view online for free. . and shearing. 3. Bending involves curving sheet metal between a punch and die. Drawing uses a punch to force sheet metal into a die cavity. .A clean surface ensures better adhesion and fewer defects during the drawing process. Annealing: Metals often need to be softened to enhance their ductility, which is critical for the drawing process. According to TWI Global, annealing involves heating the metal to a temperature of 300 – 410°C depending on the metal type and then slowly . 1. SHEET METAL PROCESSES Sheet metal characteristics - Typical shearing operations, bending and drawing operations – Stretch forming operations –– Formability of sheet metal – Test methods – Working principle .

DeepDrawing; Instead of the rollers, if the forming of the sheet metal happens through a series of die and punch then the process is called drawing. and when the depth of the drawing is more than the diameter of the component then the process is called as deep drawing. Applications and characteristics: Conventional Deep Drawing: Also known as simple deep drawing, this process involves the placement of a flat metal sheet over a die that has a cavity. The die will already be shaped like the desired final part shape, and a punch will be used to push the sheet into it, causing a seamless metal flow that eventually causes it to take the shape of .

Drawing: Drawing is a more complicated operation and is how vessels or deep depressions are formed. Tension is used to carefully draw the material into a cavity to change its shape. . piercing, or blanking process in sheet metal for your project, production will involve metal dies. Mounted on presses, dies are the fundamental tools that metal .

Sheet Metal Basics. Sheet metal is a common type of material that can be used for various applications. It is a flat and thin piece of metal that can be cut, stamped, and shaped into different forms and shapes. . Deep drawing is a process that forms sheet metal into cylindrical or box-shaped parts by pulling the metal into a die cavity with a .

PDF | In this paper, the drawing process of multi-layer sheet metal through wedge shaped die has been analyzed using stream function and upper bound. | Find, read and cite all the research you .

It is well known that deep drawing is a sheet metal forming process, which allows obtaining large lots of hollow thin-walled metal products within a sho rt period. Though the method itself is highlyToday we will learn about drawing process Working and its types like wire drawing, rod drawing and tube drawing. Drawing is a metal forming process used to reduce cross section and increase length of work piece. This process associated with tensile force which distinguishes it from other metal forming processes like extrusion, forging etc. In this process a large cross section work . What are the Different Types of Sheet Metal Forming? Sheet metal forming encompasses a variety of techniques, each tailored to specific manufacturing needs, enabling the creation of detailed, complex shapes from flat metal sheets. . Drawing refers to the process where sheet metal is stretched into a die by a mechanical action. This technique .

Sheet Metal Stamping Process. Next, let’s dive into the sheet metal stamping process. There are different types of sheet metal stamping processes, including progressive stamping, transfer stamping, and compound stamping. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. 2.1 Deep drawing: Deep drawing is a sheet metal process in which sheet metal is forced into a cup of hollow shape using tensile and compressive forces without changing its thickness. In this process, the sheet is placed over the die opening and pushed into it with a punch. A blank holder is used to hold the sheet flat on the die surface.

We provide metal stamped parts and additional stamping solutions for all complex applications in a timeframe that promises client success. We’re able to provide short-run metal parts and medium run metal parts faster than the competitor because of our in-house tooling system.

types of sheet metal drawing process|metal sheet mechanical drawings