cnc machine lockout procedure Put simply, a lockout/tagout procedure is an instructional document designed to instruct authorized employees on how to lockout a specific machine. Lockout can be defined as isolating energy sources with a lock providing . It also includes an optional rain collar for weatherproof fans. STURDY SUPPORT: You get a solid mount for fans up to 70 lbs or heavy luminaires up to 150 lbs. Our outdoor junction box is made of heavy-duty PVC and an integrated galvanized steel support bracket.

0 · twist drill lockout procedure

1 · osha minimum lockout procedure

2 · osha lockout requirements pdf

3 · osha lockout regulations

4 · osha lockout procedures pdf

5 · minimum lockout requirements

6 · minimum lockout procedures

Shop 120 gal Steel Waterproof Deck Box Gray at Target. Choose from Same Day Delivery, Drive Up or Order Pickup. Free standard shipping with $35 orders.

twist drill lockout procedure

how to test a braker in electrical box

osha minimum lockout procedure

Lockout/tagout requirements for servicing manually-controlled vertical/horizontal milling machine and drill press tool changes. OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to .This procedure establishes the minimum requirements for the lockout of energy isolating devices whenever maintenance or servicing is done on the specified machine/equipment.This procedure establishes the minimum requirements for the lockout of energy isolating devices whenever maintenance or servicing is done on machines or equipment.

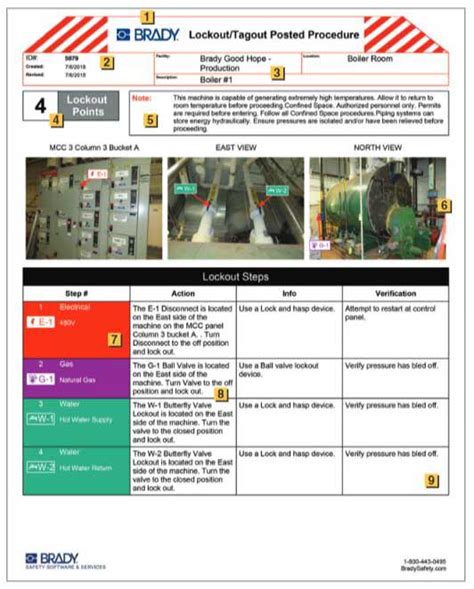

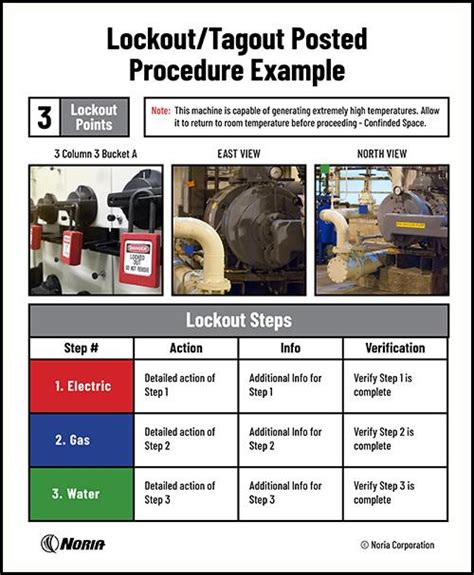

The purpose of machine-specific lockout/tagout procedures is to guide an authorized employee through a sequential process that renders a piece of equipment safe in what is referred to as a . Put simply, a lockout/tagout procedure is an instructional document designed to instruct authorized employees on how to lockout a specific machine. Lockout can be defined as isolating energy sources with a lock providing .Description: Procedure for locking out Mazak QTV250 CNC Lathe #1501 in the West Machine Shop. Notify the affected employees and identify the energy sources. Press the E-Stop button .

Lockout/tagout (LOTO) is a safety procedure that prevents the accidental start-up or release of hazardous energy from machines or equipment during maintenance or servicing. It involves isolating. Proper procedures and training protect employees from hazardous energy releases. All of these groups must understand the purpose and function of your LOTO or energy control .

how to terminate a junction box

Six Steps of LOTO Safety & Lockout/Tagout Procedures. A lockout/tagout procedure should include the following six steps: Preparation; Shutdown; Isolation; Lockout/tagout; Stored energy check; Isolation . Lockout/tagout requirements for servicing manually-controlled vertical/horizontal milling machine and drill press tool changes. OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations.This procedure establishes the minimum requirements for the lockout of energy isolating devices whenever maintenance or servicing is done on the specified machine/equipment.Steps to shut down, isolate, block and secure machines; Steps to place and remove lockout tagout devices; How to identify responsibility for lockout tagout devices; A process for testing machines to verify lockout devices and other energy-control measures are effective

This procedure establishes the minimum requirements for the lockout of energy isolating devices whenever maintenance or servicing is done on machines or equipment.The purpose of machine-specific lockout/tagout procedures is to guide an authorized employee through a sequential process that renders a piece of equipment safe in what is referred to as a zero-energy-state. In other words, all energy forms have been removed, including electrical, pneumatic, hydraulic, and any potential energy or kinetic energy. Put simply, a lockout/tagout procedure is an instructional document designed to instruct authorized employees on how to lockout a specific machine. Lockout can be defined as isolating energy sources with a lock providing physical protection, and with every lock accompanied by an information tag.

Description: Procedure for locking out Mazak QTV250 CNC Lathe #1501 in the West Machine Shop. Notify the affected employees and identify the energy sources. Press the E-Stop button on the control panel. Press the Control Power OFF (0) button on the control panel. Turn the Main Disconnect Switch OFF. Apply lock and tag.

Lockout/tagout (LOTO) is a safety procedure that prevents the accidental start-up or release of hazardous energy from machines or equipment during maintenance or servicing. It involves isolating.

Proper procedures and training protect employees from hazardous energy releases. All of these groups must understand the purpose and function of your LOTO or energy control program. Authorized employees service, maintain, and/or repair machinery; follow LOTO procedures; and apply locks and tags. Affected employees operate or use machines. When .

Six Steps of LOTO Safety & Lockout/Tagout Procedures. A lockout/tagout procedure should include the following six steps: Preparation; Shutdown; Isolation; Lockout/tagout; Stored energy check; Isolation verification; Let’s look at each of these steps of LOTO safety more closely in the sections below. Lockout/Tagout Step 1: Preparation

Lockout/tagout requirements for servicing manually-controlled vertical/horizontal milling machine and drill press tool changes. OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations.This procedure establishes the minimum requirements for the lockout of energy isolating devices whenever maintenance or servicing is done on the specified machine/equipment.Steps to shut down, isolate, block and secure machines; Steps to place and remove lockout tagout devices; How to identify responsibility for lockout tagout devices; A process for testing machines to verify lockout devices and other energy-control measures are effectiveThis procedure establishes the minimum requirements for the lockout of energy isolating devices whenever maintenance or servicing is done on machines or equipment.

The purpose of machine-specific lockout/tagout procedures is to guide an authorized employee through a sequential process that renders a piece of equipment safe in what is referred to as a zero-energy-state. In other words, all energy forms have been removed, including electrical, pneumatic, hydraulic, and any potential energy or kinetic energy.

Put simply, a lockout/tagout procedure is an instructional document designed to instruct authorized employees on how to lockout a specific machine. Lockout can be defined as isolating energy sources with a lock providing physical protection, and with every lock accompanied by an information tag.Description: Procedure for locking out Mazak QTV250 CNC Lathe #1501 in the West Machine Shop. Notify the affected employees and identify the energy sources. Press the E-Stop button on the control panel. Press the Control Power OFF (0) button on the control panel. Turn the Main Disconnect Switch OFF. Apply lock and tag.Lockout/tagout (LOTO) is a safety procedure that prevents the accidental start-up or release of hazardous energy from machines or equipment during maintenance or servicing. It involves isolating.

Proper procedures and training protect employees from hazardous energy releases. All of these groups must understand the purpose and function of your LOTO or energy control program. Authorized employees service, maintain, and/or repair machinery; follow LOTO procedures; and apply locks and tags. Affected employees operate or use machines. When .

$36.98

cnc machine lockout procedure|osha minimum lockout procedure