sheet metal selection guide RAW MATERIALS SELECTION

[email protected] | 607.227.7070 | www.incodema.com HEAT TREATABLE ALLOYS When stiffness and spring characteristics are required, the design engineer should consider the following: For parts with small radius forms, high carbon spring steel or another heat treatable metal with good ductility may need to be used.

To avoid this, cancel and sign in to YouTube on your computer. These videos from Kenney will help you install your curtain rods.

0 · sheet metal design pdf

1 · sheet metal design handbook pdf

2 · sheet metal design guidelines pdf

3 · sheet metal design guidelines

4 · sheet metal design guide pdf

5 · sheet metal design calculations pdf

6 · sheet metal design calculations

7 · sheet metal bending chart

Get the best deals for Yugioh Metal Raiders 1st Edition Booster Box at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies. The Sheet metal material selection during product design impact the sheet metal part design, manufacturing process, cost, and part performance. In this article, we will discuss .

This comprehensive guide will delve into the key factors to consider when selecting sheet metal materials, provide an overview of common alloys and grades, discuss the .Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.Xometry offers a wide selection of metal and plastic materials with various color, infill, and hardness options. These high-performance materials are matched to an extensive list of manufacturing capabilities from CNC machining, to sheet .

RAW MATERIALS SELECTION [email protected] | 607.227.7070 | www.incodema.com HEAT TREATABLE ALLOYS When stiffness and spring characteristics are required, the design engineer should consider the following: For parts with small radius forms, high carbon spring steel or another heat treatable metal with good ductility may need to be used.Discover the ultimate sheet metal selection guide! Learn the secrets of choosing the perfect metal sheet metal fabrication for your project, whether it's deep drawing material selection, stamping material selection, or more. Click now for .filler metal suggestions “match” the base metal properties; that is, the yield and tensile strength . Suggested filler metals in this Selection Guide do not always consider notch toughness (example Charpy V-Notch properties) requirements. Not all . sheet steel. (34) 761, 780, 860/L-70. .Guide and the Instructor’s Guide. The following ISBN and pricing information is for ordering individual modules only. Introduction to the Sheet Metal Trade (5 Hours) Trainee ISBN 978-0-13-604832-9 Instructor ISBN 978-0-13-604878-7 (Module ID 04101-08) Summarizes the history and development of the sheet metal trade. Explains the benefits

Sheet metal parts with a minimum of 0.9mm to 20mm in thickness can be manufactured. Hole Diameter. When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Bends. Bends in sheet metal are manufactured using sheet metal brakes. A +/- 1 degree tolerance on all bend angles.What are the best practices for sheet metal designs? The best practices for sheet metal design include material selection, bend radius, relief cuts, tolerances, and tolerancing. By designing bends, folds, and joints to meet the constraints of mandrels, we can assure manufacturability. What is the best material to use for a Sheet Metal Design

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost. . Sheet metal material selection is a critical part of product design. It has an impact on the sheet metal part design as well. . Buyer Guide (8) CAD (11) Career Advice (1) Exercise (Quiz) (6) Finish .Our guides include: Product Guide – Provides an inspiring overview of the different color solutions that Steelscape offers.; Color Design Guide – A comprehensive overview of modern color trends and finish options for metal roofs and walls.; Metal Wall Design Guide – Designed to enlighten building designers as to the shape and color possibilities available with single skin metal wall . Choosing the appropriate metal for CNC machining is crucial, as it influences both the cost-effectiveness and performance of your project. By adhering to the principles discussed in this article, you can steer clear of common mistakes and make well-informed choices, ensuring you select the optimal material for your CNC-machined metal components.

• Expanded metal sheet and perforated sheet. How Thick is Sheet Metal? To help determine the thickness of the steel sheet, please refer to this steel sheet thickness tolerance guide: Quality and Standards. To ensure quality, buy from a trusted supplier and make sure your steel sheets meet specific standards. When purchasing steel, it's . Designing and fabricating metal enclosures involves careful sheet metal material selection, precise measurements, mastering bending and forming techniques, and implementing effective quality control. However, staying updated with the latest trends and advancements is crucial as this field evolves, allowing for improved designs, enhanced product .

Common Tolerancing Problems in Metal Fabrication. We frequently receive RFQs for parts with tolerances that exceed what is achievable in standard fabrication. Most of these issues are related to sheet metal forming, such as achieving ±0.005 tolerance across multiple bends, which surpasses our recommended default sheet metal tolerances.Additionally, we .Knockout Punch Selection Guide. Not to be confused with a K.O. in boxing, a knockout tool is used to cut holes in sheet metal. All punch tools operate in a similar manner, and consist of three main parts: the draw stud, punch, and die. General Operation. 1. Drill a properly sized pilot hole. The diameter of the draw stud will determine the size .Hubei ZhongRongDa is an enterprise that integrates design, research, and the professional production of plastic shell products with full craftsmanship. It has a significant production advantage in the

sheet metal design pdf

A practical guide to the best design practices for accommodating hardware into your sheet metal parts easily and effectively. Hardware is an integral part of product design and proper specs and installation are critical. .Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication .

australian cnc machines

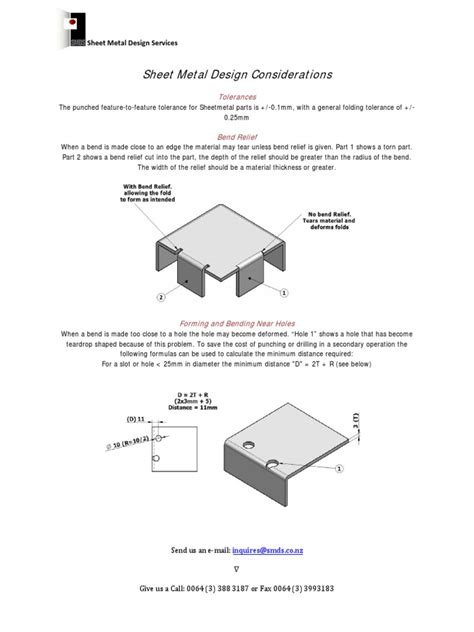

With good plasticity, toughness and weldability, it has a lower yield strength of 235MPa and ease of sheet processing. This material can be formed into many products such as I beams, channels, plates, angle bars etc. its excellent weldability makes it to be widely used in bridges, transmission towers etc.- 4 - Forming Near Holes – When a bend is made too close to a hole, the hole may become deformed. Figure "A" shows a hole that has become teardrop shaped because of this problem. To save the cost of punching or drilling in a secondary operation the following formulas can be

This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts. Search Now. Popular search terms. . Sheet metal is available in a selection of sizes, which are commonly referred to as gauges. These range from gauge 50 (or 0.03mm), to gauge 1 (7.62mm).Selection Guide (Lysaght Malaysia) - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Bluescope Lysaght is one of asia's largest rollformers with a legacy of more than 135 years worldwide and 40 years in asia. The company offers an extensive range of building solutions for roofing and walling, structural decking, rainwater goods, preengineered building . Fig. 1: Sheet Metal Parts at Komacut. In this guide, we'll look at the most common sheet metal materials used and go over the factors that need to be considered when choosing the right material. . Good corrosion resistance (Metals - Corrosion Resistance to Aggressive Fluids) is a crucial factor in sheet metal selection because corrosion can .Alloy 5005 is a non-heat-treatable 0.8% magnesium alloy that is available in flat rolled coil, plate, and sheet from an array of producing mills. The 5000-series alloys have high strengths because of the addition of magnesium, with 5005 having a very small amount, making it .

We specialize in the design and production of customized shells and casings for medium to large medical equipment as well as sheet metal processing. Our company is a leading Chinese manufacturer of CNSheet metal screws have a very sharp thread for easy installment of metal to wood or fiberglass. Shoulder screws: Image credit: Digi-Key. Visit GlobalSpec's Shoulder Screw Selection Guide and Specification Filter for tutorial information. Thumb screws: Image credit: Unicorp Inc. Thumb screws have large diameter, knurled head which allows the . The wide variety of materials Xometry provides for sheet metal are listed below to facilitate the ease of selection. The most used sheet metal materials are aluminium alloys, stainless steel and other steels containing low, moderate and high carbon content as well as non-alloy steels. Aluminium Alloys Aluminium 5052 / 3.3523 / AlMg2,5A Comprehensive Guide to Sheet Metal Selection for Your Tractor Supply Needs. As a tractor owner, you understand the importance of maintaining your machine, and when it comes to finding the perfect sheet metal for your tractor supply needs, the possibilities may seem endless. With a vast array of metals available, selecting the right one is .

sheet metal design handbook pdf

sheet metal design guidelines pdf

Corrosion-resistant stainless steel cleans easily, is nearly indestructible, and is highly animal-resistant ; Once un-stacked, each container makes its own elegant metal bowl - great for serving ; Use For: Travel, camping, picnicking, work & campus. Prevents food from being crushed during transport. Lightweight 18/8 Stainless Steel SUS304. BPA .

sheet metal selection guide|sheet metal design pdf