junction box siding Electrical code requires that all junctions be accessible in a box, so you definitely need one here. You have two choices (that I know of at least): cut a large hole . Starting with the basics, a CNC router machine is an automated machine with specialized tools that utilize a CNC system for automatic carving, cutting, engraving, drilling, and decorative grooving across an array of materials.

0 · what is a junction box

1 · vinyl siding junction box installation

2 · plastic junction box installation

3 · metal junction box

4 · junction box installation

5 · electrical junction boxes

6 · drywall junction box installation

7 · drywall junction box

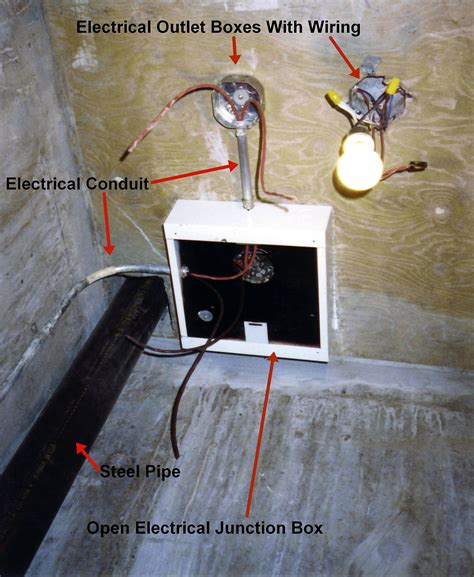

A junction box – also known as an ‘ electrical box ’, ‘ jbox ’, ‘or ‘ terminal box ’ – is a protective box where wires are interconnected. Junction boxes are often built into the plaster of a wall, in the ceiling, or within concrete. They are standard within most homes, buildings, and factories. Junction boxes are found both indoors and outdoors.

Installation of a junction box for an outdoor light outlet in the siding mounting block.How to properly install the junction box for the floodlight in the PV.

You can probably get away with a weather proof box on top of the siding, but here's the full procedure to make it look nice. Vinyl siding can be pulled off and later reattached. To remove it, you need a siding removal tool that has . A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings.Electrical code requires that all junctions be accessible in a box, so you definitely need one here. You have two choices (that I know of at least): cut a large hole .

This video focuses on adding the electrical box also known as J block to the vinyl siding. This job might seem intimidating at first glance, because it involves cutting the nice looking vinyl.Screws and Calk.. Pre-drill the back of the box, pre-drill the screws into building, take screws back out pull box off, put a medium bead around the back of the box about 1/2 3/4 of an inch from outside edge. put box into place. and re-screw. take a clean rag and wipe off extra that comes out around edges. Boom done, won't leak never will move.The old lights had no junction box, there was just a hole cut into the siding and plywood for the electrical, and the lights were mounted directly to the siding. . The existing hole in the siding box is around 1-1/8”, so if you have a 1-1/8” hole .What are some of the most reviewed products in Mounting Blocks? Some of the most reviewed products in Mounting Blocks are the Builders Edge 7 in. x 8 in. #123 White Scalloped Mounting Block with 11 reviews, and the ClipStone 6 in. .

The junction box is protruding ~1/4 inch from the siding. I'm wondering about two things: they cut the siding around the junction box, is that the correct way to do this? what if water gets behind the siding into the junction box? If i install a fixture on this, it .Would just like to point out that with different types of siding, a “siding box” won’t always work, ie: cedar shakes, shiplap. So the box in the first picture is actually an appropriate box for the application, commonly called a RAB box (RAB being the brand). Water gets behind vinyl siding and can run in the wall at that box. The assemblies used for vinyl siding should come with their own junction box. The idea is that the junction box gets mounted and sealed to the sheathing. Then the box protrudes thru the siding for .

This should complement the existing angle and give you a vertical surface. This should be possible as long as your siding has a vertical plane on the back and a consistent angle on the front (i.e. a triangular or trapezoidal profile). If you do install a mounting block or cut the siding, make sure to waterproof any siding penetrations . When discussing how to size junction boxes, it is best to consider some situational examples. For our first example, let's say we need to attach two 1½" conduits to the left side of our junction box, where we'll pull wires horizontally to the right side of the box with one 2½" conduit.. According to the 2020 NEC®, our box should have a size of at least eight times the largest .I've considered junction box extenders (like this one) to move the outlet box out to the edge of the trim, but this would require re-cutting the holes and the extender actually goes TOO far (past the face of the blocking). I called an electrician as well, and they said that the correct way to do it would have been to remove the old outlet boxes . A simple guide to setting up an electrical junction box Junction boxes protect electrical wires from damage, prevent shocks, and stop sparks from igniting flammable material nearby. To install one, you'll need to strip the ends off all the.

Siding installers will just screw light fixture into that mounting block instead of into junction box behind it. Correct fix will be removing mounting block, install junction box, then put mounting block over the junction box. Cut mounting block to match size of junction box. In order to remove mounting block, you will have to remove siding .

8141DBL Siding Mounting Kit, Vinyl siding mounting Blocks,Outdoor Light Mounting Block with Built-in Electrical Box,Siding Mounting Plate for 1/2 inch Lap Double and 4 inch Siding-White. . I connected the inside junction box to the mount with conduit. Worked like a charm:) Images in this review Helpful. Report. Mike. Most fixtures come with a gasket that goes between the fixture and the mounting surface. A flat surface is necessary for the gasket to do its job of keeping moisture and debris out of the junction box. The house in this demo has classic double 4-inch vinyl siding. This is the most common type of siding that you’ll see on any modern home. Install a cable connector in the junction box where you’ll be connecting. Install another cable connector in the device box where the new cable will terminate. Cut the cable to a length extending at each box’s front. Tighten the clamping screws on the cable connections to secure the cable in the boxes. Use Cable Staples To Secure The Walls

what is a junction box

Make sure the junction box is large enough to hold an added set of wires. An overstuffed box is a fire hazard. If the box is plastic, shine a flashlight inside and look for a volume listing, such as 21 cu. in. (cubic inches). Pro tip: If .LEONLITE 12 Pack Old Work Electrical Outlet Box One Gang, Ultra-deep 20 Cubic Inch Device Box, PVC Electrical Junction Box for Switch, GFCI, Outlet Box for Home Improvement, ETL Listed, Gray 4.3 out of 5 stars

Plenty of screw holes in that junction box to secure the mounting bracket that comes with the Floodlight. The only issue I see is the uneven siding. The mount bracket has a relatively thin foam gasket around it, intended to provide weather sealing to whatever you're mounting it to, assuming it's a flat surface which yours is not.

Welcome to Reddit's own amateur (ham) radio club. If you are wondering what Amateur Radio is about, it's basically a two way radio service where licensed operators throughout the world experiment and communicate with each other on frequencies reserved for license holders. This vinyl siding mounting kit by Arlington, makes installing an exterior box super easy. You don't even need to add an electrical box since the unit is desi. 314.19 Boxes Enclosing Flush Devices. Boxes used to enclose flush devices shall be of such design that the devices will be completely enclosed on back and sides and substantial support for the devices will be provided. Screws for supporting the box shall not be used in attachment of the device contained therein.

The boxes have adjustable rings to get to the thickness you want. I bring it to about the thickness of the block mounted over it. They are *not* recessed into the sheathing. > I never thought of junction boxes as something you'd want to see protruding way out past your siding. What am I missing? I agree with not wanting them to protrude.6-3/4" Non-Metallic Flange and Fixture Box For Flat and Stucco Surfaces Would that create an adequate installation, or do I need to get more involved with cutting the siding and installing the electrical box in a siding j-block? I would of course use screws long enough to secure the electrical box and siding block to the rim joist and use a weatherproof box, receptacle, and in-use weatherproof cover.

I am working on putting new vinyl siding on my home, and im wanting to put two lights on the sides of my french door. This will be new construction since I recently rebuilt the wall to accept the french door. . That would effectively make up a majority of the gap between the junction box and the light base. Top. Shannon Posts: 21872 Joined .Problem I'm seeing is that the junction box is just mounted to the siding instead of being recessed in the wall. The light attaches to the junction box but there's obviously a gap in the area between the junction box and light housing because they're not the same size. Would appreciate any advice/help on the best way to mount a Ring Floodlight circular mounting bracket to a rectangular junction box (please see pic)? Mounting a Ring Floodlight to a rectangular junction box (lights, siding, best) - House -remodeling, decorating, construction, energy use, kitchen, bathroom, bedroom, building, rooms - City-Data Forum Metal boxes are usually made of aluminum, steel or cast iron. The boxes made without metal are PVC or plastic. Metal Boxes: Many local building codes require metal junction boxes because they are durable and ensure long-lasting performance. Choose from many junction box sizes to find the one that best suits your project.

vinyl siding junction box installation

cnc grinding plastic part

cnc horizontal lathe machine quotes

plastic junction box installation

Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final shape.

junction box siding|drywall junction box