cnc 6040 machining aluminium Using the engraver/mill to cut an aluminum part. No coolant. Spindle speed of 11K RPM. Taking a cut 0.25mm deep by 1mm wide using a 6.36mm (1/4")solid carbid. Normally 18-gauge sheet metal is used for body panels. Mild steel gets priority here and some racers choose 20-gauge sheet metal over 18 gauge. Then they start working to lighten mechanisms up.

0 · vevor 6040 cnc router review

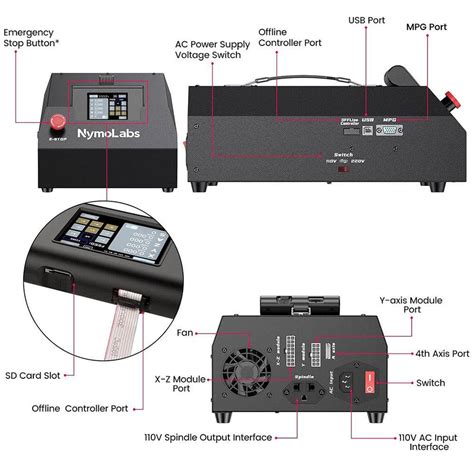

1 · nymolabs nbs 6040

2 · cncest 6040 manual pdf

3 · cncest 6040 manual

4 · cnc 6040 router user manual

5 · cnc 6040 router

6 · 6040 cnc router set up

7 · 6040 cnc router manual

Sheet metal paint is available in both spray paint and brush-on options. Both types of paint work well for home decorating purposes. Choose a brush or roller size appropriate for your sheet metal project.

Using the engraver/mill to cut an aluminum part. No coolant. Spindle speed of 11K RPM. Taking a cut 0.25mm deep by 1mm wide using a 6.36mm (1/4")solid carbid. A Roger C b CNC build Router tutorial The Australian Inventors Workshop™ 2022 Video 732 6040 CNC Router milling and cutting ½ inch Aluminium plateThank y.In this video I’ll take you through my first experience with milling Aluminium on my CNC 6040 Router. I’ve broke some tools, burned some aluminium and finally got things working pretty. Using the engraver/mill to cut an aluminum part. No coolant. Spindle speed of 11K RPM. Taking a cut 0.25mm deep by 1mm wide using a 6.36mm (1/4")solid carbid.

vevor 6040 cnc router review

nymolabs nbs 6040

A Roger C b CNC build Router tutorial The Australian Inventors Workshop™ 2022 Video 732 6040 CNC Router milling and cutting ½ inch Aluminium plateThank y.CNC 6040 is a popular milling machine used for aluminum milling, offering precision and efficiency. In this blog post, we will provide you with a comprehensive guide on CNC 6040 milling aluminum, covering its benefits, applications, techniques, and essential tips. Learn the best tips and secrets for cutting aluminum with a CNC router, including feeds and speeds for a successful project. Master aluminum cutting with this ultimate guide.

I have a 6040 CNC machine with an 800W watercooled brushless motor. Using Artcam Express 2013, Mach3 and a UC100 motion controller. With this setup, I can quite happily design and mill 2D shapes, usually in MDF.

I'm using a 3/8" carbide profile boring bar and kinda breaking chips at 4000rpm and 0.005"/rev using a 0.008"NR insert specific for aluminum. I want to goto a higher SFM but the bar chatters due to the stick out. The Carving-CNC 6040 machine with 1.5kW spindle that I have will certainly mill aluminium, but not very quickly. I'm waiting on some more end mills to do more testing, but so far I was getting a 0.5mm DOC at 600mm/min with a 3mm dual spiral-flute end mill.NBS-6040 CNC Router Machine with Custom-Made 710W 7000-30000 RPM Trim Router Spindle & ER-11 Collet, Linear Rails & Ball Screws on 3-axis, Engraving for Wood Acrylic Aluminum

3 types of cnc machine

cncest 6040 manual pdf

3.5 inch junction box

This is our 6040 CNC mill cutting aluminum on the first "big" job. This video shows milling from the second (top) side.Part 1/2 here: https://www.youtube.com.In this video I’ll take you through my first experience with milling Aluminium on my CNC 6040 Router. I’ve broke some tools, burned some aluminium and finally got things working pretty. Using the engraver/mill to cut an aluminum part. No coolant. Spindle speed of 11K RPM. Taking a cut 0.25mm deep by 1mm wide using a 6.36mm (1/4")solid carbid. A Roger C b CNC build Router tutorial The Australian Inventors Workshop™ 2022 Video 732 6040 CNC Router milling and cutting ½ inch Aluminium plateThank y.

CNC 6040 is a popular milling machine used for aluminum milling, offering precision and efficiency. In this blog post, we will provide you with a comprehensive guide on CNC 6040 milling aluminum, covering its benefits, applications, techniques, and essential tips.

Learn the best tips and secrets for cutting aluminum with a CNC router, including feeds and speeds for a successful project. Master aluminum cutting with this ultimate guide. I have a 6040 CNC machine with an 800W watercooled brushless motor. Using Artcam Express 2013, Mach3 and a UC100 motion controller. With this setup, I can quite happily design and mill 2D shapes, usually in MDF. I'm using a 3/8" carbide profile boring bar and kinda breaking chips at 4000rpm and 0.005"/rev using a 0.008"NR insert specific for aluminum. I want to goto a higher SFM but the bar chatters due to the stick out.

The Carving-CNC 6040 machine with 1.5kW spindle that I have will certainly mill aluminium, but not very quickly. I'm waiting on some more end mills to do more testing, but so far I was getting a 0.5mm DOC at 600mm/min with a 3mm dual spiral-flute end mill.NBS-6040 CNC Router Machine with Custom-Made 710W 7000-30000 RPM Trim Router Spindle & ER-11 Collet, Linear Rails & Ball Screws on 3-axis, Engraving for Wood Acrylic Aluminum

cncest 6040 manual

3 pole junction box

Long lasting colognes exist for all of those reasons. Some are fresh, some are deep and woody, and all of them negate the need to reapply. It’s not just about sillage, the fancy fragrance-speak.

cnc 6040 machining aluminium|cncest 6040 manual pdf