capability of cnc machine CNC machines follow a predefined process to remove material from a blank or workpiece, resulting in the production of intricate and complex parts. They enable manufacturers to achieve high levels of precision, . Home > Body Parts > Sheet Metal Parts > Wagon & Delivery > Right Quarter Panel .

0 · how many axis are there

1 · how does cnc machine work

2 · high end cnc machines

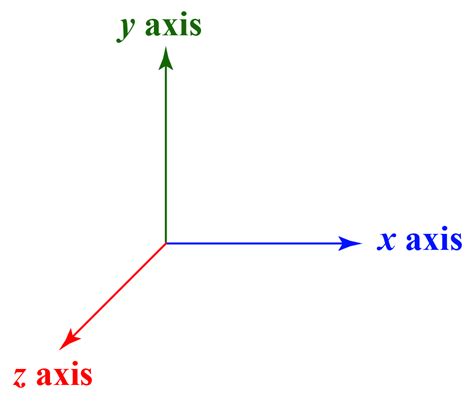

3 · cnc mill axis diagram

4 · cnc machining guide

5 · cnc machine how it works

6 · cnc machine advantages and disadvantages

7 · 5 axis vs 6 cnc

$169.99

Explore cutting-edge CNC machine capabilities and their wide range of applications. Achieve exceptional quality and efficiency with precise engineering. Delve into the types and capabilities of CNC machines, empowering engineers with a comprehensive understanding of their diverse applications. This guide equips engineers to leverage CNC technology for .In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the . Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC .

CNC machines follow a predefined process to remove material from a blank or workpiece, resulting in the production of intricate and complex parts. They enable manufacturers to achieve high levels of precision, .In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the .

Key features include multi-axis capabilities, enabling intricate 3D cuts and shapes; tool changers for seamless switching between operations; and advanced control systems that interpret CAD/CAM designs into precise machine movements. CNC machines also boast high-speed machining capabilities, reducing production time while maintaining accuracy. There are 15 different types of CNC machines, each with their own unique capabilities. The most common types include milling machines, lathes, routers, and grinders. These are the 15 types of CNC I’ll cover in this article: 1. CNC Routers. CNC routers have a large bed for laying sheet material.

sheet metal minimum hole to edge distance

Explore cutting-edge CNC machine capabilities and their wide range of applications. Achieve exceptional quality and efficiency with precise engineering. Delve into the types and capabilities of CNC machines, empowering engineers with a comprehensive understanding of their diverse applications. This guide equips engineers to leverage CNC technology for innovative solutions across industries.In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc. CNC machining services use a subtractive fabrication method. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .

CNC machines follow a predefined process to remove material from a blank or workpiece, resulting in the production of intricate and complex parts. They enable manufacturers to achieve high levels of precision, consistency, and efficiency.In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes. Standing for Computer Numerical Control, CNC milling leverages computerized systems to control the movement and operation of the cutting tools with extreme precision.CNC mills are computerized manufacturing machines that travel cutting tools on a variety of axes of travel, to shape and cut materials such as metal, wood, plastics, and composites into precision parts that faithfully reproduce a CAD design file.

Key features include multi-axis capabilities, enabling intricate 3D cuts and shapes; tool changers for seamless switching between operations; and advanced control systems that interpret CAD/CAM designs into precise machine movements. CNC machines also boast high-speed machining capabilities, reducing production time while maintaining accuracy.

There are 15 different types of CNC machines, each with their own unique capabilities. The most common types include milling machines, lathes, routers, and grinders. These are the 15 types of CNC I’ll cover in this article: 1. CNC Routers. CNC routers have a large bed for laying sheet material.

Explore cutting-edge CNC machine capabilities and their wide range of applications. Achieve exceptional quality and efficiency with precise engineering. Delve into the types and capabilities of CNC machines, empowering engineers with a comprehensive understanding of their diverse applications. This guide equips engineers to leverage CNC technology for innovative solutions across industries.In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc. CNC machining services use a subtractive fabrication method. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .

CNC machines follow a predefined process to remove material from a blank or workpiece, resulting in the production of intricate and complex parts. They enable manufacturers to achieve high levels of precision, consistency, and efficiency.

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes. Standing for Computer Numerical Control, CNC milling leverages computerized systems to control the movement and operation of the cutting tools with extreme precision.

how many axis are there

Winco Sfac-12 Stainless Steel First Aid Cabinet, 12 In.x12 In.x4-3/4 In. US $450. Brooklyn, New York, United States; Jun 12th; Contact Seller Complain

capability of cnc machine|cnc machine how it works