bulk deformation processes and sheet metal processes There are three types of metal forming processes: bulk metal forming, sheet metal forming, and sheet-bulk metal forming. Some popular metal forming processes are forging, rolling, wire . $12.99

0 · metal deformation process

1 · material deformation process

2 · manufacturing deformation process

3 · load estimation for bulk forming

4 · bulk metal deformation

5 · bulk forming process

6 · bulk deformation vs metal forming

7 · bulk deformation process

Designed to meet American Electric Power standards for current transformer enclosures Many sizes~ styles~ back panel and customization options available Featured image is AEP484812DDCT3An Independent, Texas-based producer of electrical enclosure solutions. Our approach to listening to our customers’ concerns and understanding their challenges allows us to design .

Bulk deformation and sheet metal forming are two common manufacturing processes used to shape metals into desired forms. While both methods involve the deformation of metal, they differ in terms of the starting material, the types of products produced, and the specific techniques .Deformation processes can be conveniently classified into bulk-forming processes (e.g., rolling, extrusion, and forging) and sheet-forming processes (e.g., stretching, flanging, drawing, and .

This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal .Bulk forming processes Forging • It is a deformation process in which the work piece is compressed between two dies, using either impact load or hydraulic load (or gradual load) to .There are three types of metal forming processes: bulk metal forming, sheet metal forming, and sheet-bulk metal forming. Some popular metal forming processes are forging, rolling, wire .Sheet Metalworking: Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. The surface area-to-volume ratio of the starting metal is high; thus, this ratio is a useful means to .

metal deformation process

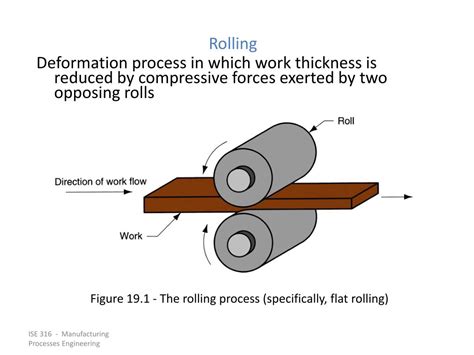

These interactions are demonstrated by selected examples of both bulk and sheet metal forming. In this connection special processes, such as superplastic forming, thermomechanical.Four Basic Bulk Deformation Processes 1. Rolling –slab or plate is squeezed between opposing rolls 2. Forging –work is squeezed and shaped between between opposing dies 3. Extrusion .–Primary processes reduce a cast material into slabs, plates, and billets –Secondary processes reduce shapes into finished or semifinished products •Bulk deformation processes are those .

Bulk deformation and sheet metal forming are two common manufacturing processes used to shape metals into desired forms. While both methods involve the deformation of metal, they differ in terms of the starting material, the types of products produced, and .Deformation processes can be conveniently classified into bulk-forming processes (e.g., rolling, extrusion, and forging) and sheet-forming processes (e.g., stretching, flanging, drawing, and contouring).Sheet Metalworking: Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. The surface-area-to-volume ratio of the starting metal is high; thus, this ratio is a useful means to distinguish bulk deformation from sheet metal processes.This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal forming, sheet-metal forming, and sheet-bulk-metal forming.

Bulk forming processes Forging • It is a deformation process in which the work piece is compressed between two dies, using either impact load or hydraulic load (or gradual load) to deform it. • It is used to make a variety of high-strength components for automotive, aerospace, and other applications.There are three types of metal forming processes: bulk metal forming, sheet metal forming, and sheet-bulk metal forming. Some popular metal forming processes are forging, rolling, wire drawing, extrusion, deep drawing, and bending.Sheet Metalworking: Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. The surface area-to-volume ratio of the starting metal is high; thus, this ratio is a useful means to distinguish bulk deformation from sheet metal processes.

These interactions are demonstrated by selected examples of both bulk and sheet metal forming. In this connection special processes, such as superplastic forming, thermomechanical.Four Basic Bulk Deformation Processes 1. Rolling –slab or plate is squeezed between opposing rolls 2. Forging –work is squeezed and shaped between between opposing dies 3. Extrusion –work is squeezed through a die opening, thereby taking the shape of the opening 4. Wire and bar drawing –diameter of wire or bar is

–Primary processes reduce a cast material into slabs, plates, and billets –Secondary processes reduce shapes into finished or semifinished products •Bulk deformation processes are those processes where the thickness or cross sections are reduced •Sheet-forming operations involve the deformation

Bulk deformation and sheet metal forming are two common manufacturing processes used to shape metals into desired forms. While both methods involve the deformation of metal, they differ in terms of the starting material, the types of products produced, and .Deformation processes can be conveniently classified into bulk-forming processes (e.g., rolling, extrusion, and forging) and sheet-forming processes (e.g., stretching, flanging, drawing, and contouring).Sheet Metalworking: Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. The surface-area-to-volume ratio of the starting metal is high; thus, this ratio is a useful means to distinguish bulk deformation from sheet metal processes.

This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal forming, sheet-metal forming, and sheet-bulk-metal forming.Bulk forming processes Forging • It is a deformation process in which the work piece is compressed between two dies, using either impact load or hydraulic load (or gradual load) to deform it. • It is used to make a variety of high-strength components for automotive, aerospace, and other applications.There are three types of metal forming processes: bulk metal forming, sheet metal forming, and sheet-bulk metal forming. Some popular metal forming processes are forging, rolling, wire drawing, extrusion, deep drawing, and bending.Sheet Metalworking: Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. The surface area-to-volume ratio of the starting metal is high; thus, this ratio is a useful means to distinguish bulk deformation from sheet metal processes.

These interactions are demonstrated by selected examples of both bulk and sheet metal forming. In this connection special processes, such as superplastic forming, thermomechanical.Four Basic Bulk Deformation Processes 1. Rolling –slab or plate is squeezed between opposing rolls 2. Forging –work is squeezed and shaped between between opposing dies 3. Extrusion –work is squeezed through a die opening, thereby taking the shape of the opening 4. Wire and bar drawing –diameter of wire or bar is

material deformation process

manufacturing deformation process

load estimation for bulk forming

electric swiss room box

Unturned Weapons and Ammo ID List; Unturned Weapon Attachments ID List; Unturned Food and Medical Suply ID List; Unturned Tools, Melee & Throwable ID List; . 67 = Metal Scrap; 68 = Metal Sheet; 69 = Tape; .

bulk deformation processes and sheet metal processes|material deformation process