cnc machine coolant price $239.99 With butt welding, the panel has the same stiffness as the original. You can work the weld joint with a hammer and dolly and get some of the inevitable warpage out of the joint. Taken to extreme, it's possible to metalwork and metal finish the panel to the point where the weld seam is "invisible".

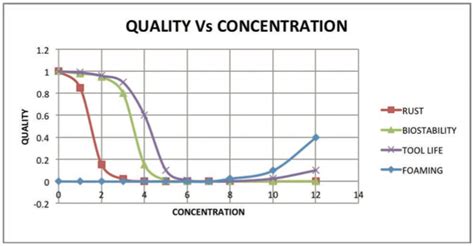

0 · machine coolant concentration chart

1 · coolant tank for cnc machine

2 · coolant system for milling machine

3 · coolant mixers for cnc equipment

4 · coolant concentration for cnc machines

5 · cnc machine coolant suppliers

6 · best semi synthetic machine coolant

7 · best coolant for cnc machine

Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application.

Advanced General Purpose Coolant for Cutting and Grinding Machine Shop Operations | Ultimate Human/Enviro Friendly | Fusion Hybrid Cool (1 Gallon)CLIsyntec Premium Synthetic Coolant is the latest generation of a true oil-free .9.99.99

.889.95Keep Tools Cool and Happy with Fusion Cool 2240 Flood Coolant for the MR-1 CNC Gantry Mill. Includes: Fusion is crafted as a biodegradable, semi-synthetic cutting fluid, offering seamless disposal without compromising its effectiveness.

CLIsyntec Premium Synthetic Coolant is the latest generation of a true oil-free synthetic solution designed for use in multi-metal machining and . Top CNC coolant brands include Benz, ICC, Master Chemical, Blaser Swisslube, and Milacron. Selecting the right CNC coolant is crucial for top machining performance. Coolants impact tool life, efficiency, and fluid .High-performance metalworking fluids, CNC process optimization, and support services. Blaser Swisslube has been helping customers succeed for over 80 years.

Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid .Advanced General Purpose Coolant for Cutting and Grinding Machine Shop Operations | Ultimate Human/Enviro Friendly | Fusion Hybrid Cool (1 Gallon)

Keep Tools Cool and Happy with Fusion Cool 2240 Flood Coolant for the MR-1 CNC Gantry Mill. Includes: Fusion is crafted as a biodegradable, semi-synthetic cutting fluid, offering seamless disposal without compromising its effectiveness.

CLIsyntec Premium Synthetic Coolant is the latest generation of a true oil-free synthetic solution designed for use in multi-metal machining and grinding applications. This formula has been tested and proven to provide optimum, long-lasting performance in a variety of CNC machining and grinding applications. Top CNC coolant brands include Benz, ICC, Master Chemical, Blaser Swisslube, and Milacron. Selecting the right CNC coolant is crucial for top machining performance. Coolants impact tool life, efficiency, and fluid consumption by reducing heat, friction, and debris. What is the Right Coolant for Your CNC Machine? Using water alone as a coolant is never a good idea since it’s the additives in the fluid that prevent damaging rust and corrosion. Typically, most CNC machine tools use one of the following .

machine coolant concentration chart

High-performance metalworking fluids, CNC process optimization, and support services. Blaser Swisslube has been helping customers succeed for over 80 years.

Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid chip removal. I've also been looking at switching to this stuff. What prices are you guys paying? The only distributor for me wants 250 dollars for a 5 gallon bucket, I would need 2 of those for my machine. The coolant I'm using now is half the price.The new standard coolant for bio-stable, high-pressure delivery machining systems.

Discover the best CNC coolant for your needs with our buyer's guide. Compare top products, learn proper usage, and optimize your machining process!

Advanced General Purpose Coolant for Cutting and Grinding Machine Shop Operations | Ultimate Human/Enviro Friendly | Fusion Hybrid Cool (1 Gallon)Keep Tools Cool and Happy with Fusion Cool 2240 Flood Coolant for the MR-1 CNC Gantry Mill. Includes: Fusion is crafted as a biodegradable, semi-synthetic cutting fluid, offering seamless disposal without compromising its effectiveness. CLIsyntec Premium Synthetic Coolant is the latest generation of a true oil-free synthetic solution designed for use in multi-metal machining and grinding applications. This formula has been tested and proven to provide optimum, long-lasting performance in a variety of CNC machining and grinding applications. Top CNC coolant brands include Benz, ICC, Master Chemical, Blaser Swisslube, and Milacron. Selecting the right CNC coolant is crucial for top machining performance. Coolants impact tool life, efficiency, and fluid consumption by reducing heat, friction, and debris.

What is the Right Coolant for Your CNC Machine? Using water alone as a coolant is never a good idea since it’s the additives in the fluid that prevent damaging rust and corrosion. Typically, most CNC machine tools use one of the following .High-performance metalworking fluids, CNC process optimization, and support services. Blaser Swisslube has been helping customers succeed for over 80 years.

Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid chip removal.

I've also been looking at switching to this stuff. What prices are you guys paying? The only distributor for me wants 250 dollars for a 5 gallon bucket, I would need 2 of those for my machine. The coolant I'm using now is half the price.The new standard coolant for bio-stable, high-pressure delivery machining systems.

coolant tank for cnc machine

Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application.

cnc machine coolant price|machine coolant concentration chart