mig welding body sheet metal The problem with welding sheet metal or thin gauge steel is that you can easily blow holes in the panel and create a big mess quickly. We decided to give you some tips when .

CNC milling is the same milling machining process that we know and love, with the addition of computer control. Milling is the cutting of a material like metal, plastic, or wood, using a rotating tool. Every aspect, like cutter .

0 · welding 20 gauge sheet metal

1 · welding 14 gauge sheet metal

2 · welder settings for sheet metal

3 · mig welding travel speed chart

4 · mig welding thin metal videos

5 · mig welding sheet metal basics

6 · mig welding automotive sheet metal

7 · best welding for thin metal

Alluminum Alloy Wire intake junction box for LTS CMHT17XX, CMHT27XX, CMIP11XX, CMIP30XX series turret cameras. This indoor/outdoor junction box allows most turret cameras to be mounted on wall or ceiling while hiding the cables at the same time.

Are you planning to weld auto body sheet metal or any thin metal with a MIG welder or tig welder? You should keep in mind some critical things to avoid creating any unwanted situations, and we have decided to incorporate them right here. See more Learn how to MIG weld automotive sheet metal in about 5 minutes or less! I keep it short and to the point in this welding instructional video and show how very easy it is to start . Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and TIG welding. In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and weld it in. I .

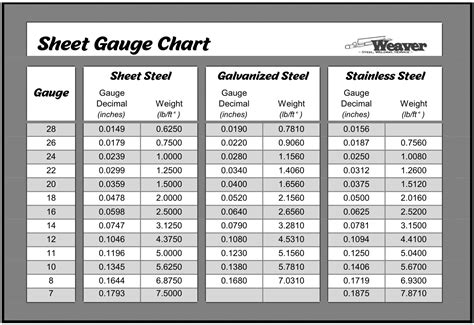

Find below the MIG Welding Sheet Metal Settings Chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. To ensure optimal results, select the appropriate gauge thickness .

The problem with welding sheet metal or thin gauge steel is that you can easily blow holes in the panel and create a big mess quickly. We decided to give you some tips when . Here's some tips if you're having trouble mig welding thin sheet metal. Check out my custom mini parts available:Urchfab Front Subframe Kit: https://www.ebay.

MIG welding machines are the most popular piece of equipment for repairing car parts, specifically car panels. However, getting the MIG welder’s settings just right is key to a successful weld. For filler metal selection, the . Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these common tips to help ensure success.

welding 20 gauge sheet metal

Mig welding, also known as Gas Metal Arc Welding (GMAW), is a popular method for welding sheet metal due to its speed and versatility. It uses a continuous solid wire electrode . I welded up some sheet metal with my new to me MM250 with the standard .035 wire. The tack, tack, tack method worked great for me and can be fast once you get into it. This was my second actual MIG weld I done going from the sheet metal to 1/4" box tube.Be aware that MIG welding is a much better method to be used on sheet metals and body panels, though . their usual choice while welding body panels and sheet metals would be MIG welding. . There are a lot of places on the .

FLUX CORE WELDING AUTO BODY PANELS. Next get your sheet metal setup. Make sure the sheet metal is the weldable kind and get it a clean with a wire wheel or sander. I’d also recommend practicing with a butt .

In this video I show you how to properly set up your welder settings for thin sheet metal welding on automotive car or trucks repairs for beginners.In this v.

Plug welding kits include pre-cut blanks in multiple sizes plus a step-style bit for drilling sheet metal. Sheet metal patch – If you lose control of the blow-through altogether, you may need to remove the damaged area entirely and start over. Grind out the damage and cut a patch panel from another piece of sheet metal just large enough to . Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several . Aluminum welding will also require 100% argon gas instead of the usual 75%/25% argon/CO2 mix. Speed – MIG welding is generally faster than TIG welding, especially for those who may not weld very often. For thin metal like body panels, MIG welding requires stitching together a series of spot welds to create a complete seam. Browse suggested weld parameter settings for Stick Welding, TIG Welding, MIG (Solid-Wire) Welding and MIG (Flux-Core) Welding. They show .030 for 22 gauge.I have been using .035 on my panels.but it's a bit of work trying not to burn through..but I have been doing it directing the heat towards the new steel and letting it flow over.

MIG welding is the preferred method for most automotive bodywork, and since sheet metal is the thinnest of metals, a large, expensive MIG unit is usually not required.. The majority of sheet metal repair that I've done was with a 90-amp, 110-volt welder. There's nothing wrong with using a larger machine, it's just not necessary when welding thin metal. Lap welding auto body sheet metal with a MIG welder is made easy in the short video. Concentrates on tips that can help make your welding more robotic, neat.You'll never warp another panel again after watching this video. This is a realtime, step by step demonstration that shows how to mig weld sheet metal withou. For thinner gauge sheet metal like 18 or 20 gauge we suggest .023 (6mm) wire in your MIG welder. Keep the Stick Out Short-Stickout of your MIG wire is important when welding any type of metal, but especially sheet metal. Holding the tip too far from the surface will cause the wire to have to come out too far to touch the metal.

For a machine that you can use for both MIG and TIG weld auto-body work, we highly recommend this small multi-process welder. It’s low-priced, and while it doesn’t have the same TIG settings as the PRIMEWELD TIG225X 225 Amp TIG Welder, it’s excellent for beginners and experienced welders alike.. It’s particularly easy to learn on or develop new .MIG Yes. MIG welding stands for "Metal- Inert Gas." By definition MIG requires a bottle of inert shielding gas, often 25% CO2 and 75% Argon. This is ideal for things like auto body tnin sheet metal. Although a seperate shield gas is often used industrially for flux core welding. Some wire types don't need an external shield. Sheet metal MIG Welding 101Episode 85 Manic MechanicRobert McCartney from McCartney Paint and Custom came in to give welding tips for those using a MIG welde. You don't need TIG for sheet metal; you just need the right settings and a lesson—like all of us do. Most auto body shops don't use TIG for panels; they use MIG, and that says a lot. Your machine can work fine, with a few operator tricks. The biggest mistakes with sheet metal welding are gap and heat. Flux core is way harder to do on thin metal.

All the information that you can find on this Forum about MIG welding thin sheet metal refers to the need for low current settings, typically 20 to 30 Amps. . @eddie49 yes I also read that 20-30A were needed for thin materials such as auto body panels but was puzzled to see this guy achieving good results with this LIDL welder starting at 50A .

Try to use a two-stage regulator that employs a volume indicator in its second stage. About 10 to 20 CFM (at atmospheric pressure) is a good range in which to work when you are welding body metal with .023- to .025-inch wire. Practice and experimentation are your best guides in this matter. Amperage settings are critical when MIG welding .

In this video I show how to set up your mig welder to be able to weld on super thin metal with out warping it. I go through step by step comparing how to pre. |Starting from scratch and setting up two different mig welders to weld sheet metal I assume the MIG is probably good for body work. . To add to this, I have a Lincoln stick welder for anything really big and was thinking of picking up this for sheet metal welding. Browser Level Verification My thought was that having a 110v welder might be a little more versatile than a 220v input, and I am only looking to weld lighter .

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt. Here's a quick video on how to plug weld sheet metal using mig without blowing yourself a bigger hole than you started with. My names Matt Urch and I own an.

Overview of Welding Techniques for Auto Body Repair A. MIG Welding. Metal Inert Gas (MIG) welding is a versatile technique favored for its speed and efficiency. It’s particularly suitable for steel and aluminum, making it a go-to option for many auto body repairs. . Spot welding is efficient for joining sheet metal, replicating factory . To weld sheet metal with solid wires, use electrode positive (EP, or reverse polarity). Don’t attempt to weld thin materials like sheet metal with flux-cored wires, which put more heat into the base metal. TIG welding sheet metal. Forget the larger 1/8-inch tungsten electrode and use a smaller one.An easy explanation of how to plug weld auto body sheet metal and prevent the newly formed pinch weld from rusting between the layers of metal.https://www.yo.

petsmart electric litter box

pharmacy large bath cabinet burnished steel

The average electric lunch box has two compartments, just like a regular lunch box, and a socket that connects it to electricity source to heat up your food when needed. These two compartments of the lunch box are removable, .

mig welding body sheet metal|welding 20 gauge sheet metal