dimensioning sheet metal drawings It’s a good practice to build your own manufacturing process specific checklists for your part designs and engineering drawings. Make sure to include the items covered in this article, plus any specifications or design patterns that are common to your designs. If you want a starting point for this checklist in pdf, Google sheets, or notion template. See more Used lathes for sale in USA. Haas, Hardinge, Clausing, JET, and Lansing. Find CNC, center and vertical turret lathes on Machinio.

0 · sheet metal layout drawings

1 · sheet metal drawing symbols

2 · sheet metal dimensioning standards

3 · sheet metal dimensioning guidelines

4 · sheet metal diagram fabrication

5 · sheet metal design basics

6 · sheet metal basic drawing

7 · sheet metal basic design guidelines

$395.00

sheet metal layout drawings

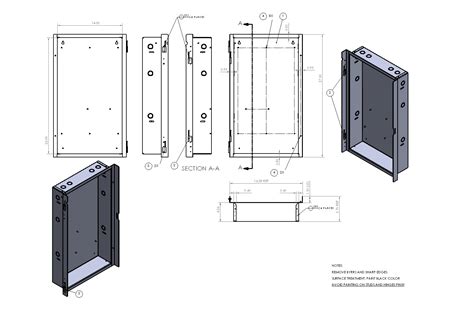

In this section we will be considering four foundational DFM considerations in order to create great sheet metal drawings. 1. Manufacturing process mapping 2. Flat pattern process considerations 3. Bending specific design considerations 4. Default tolerances See moreJust like any other part drawing, there are some standard items you will need to include on your sheet metal drawings in order to generate easy to interpret 2D drawings that . See more

sheet metal drawing symbols

Because sheet metal components require multiple manufacturing processes, proper file preparation can speed up both the quoting and production processes. The first step is to . See more

For the sake of completeness and clarity, we’ve included downloadable example files below that represent a typical set of complete manufacturing output files. PDF B - size drawing DXF file with boarders, dimensions, and all annotations removed STEP file of 3d geometry See more

It’s a good practice to build your own manufacturing process specific checklists for your part designs and engineering drawings. Make sure to include the items covered in this article, plus any specifications or design patterns that are common to your designs. If you want a starting point for this checklist in pdf, Google sheets, or notion template. See more

Generally, dimensioning should be done from a feature to an edge. Avoid feature-to-feature dimensions over two or more planes. Feature-to-bend dimensions may require special fixtures .

requirements for sheet metal part drawings Sheet metal parts are typically created from material less than .250 inches thick, and are formed by folding the material at specific . Sheet metal drawings provide detailed dimensions, tolerances, and material requirements, helping manufacturers accurately understand design intent and produce products that meet specifications.

Two-dimensional (2D) drawings are fundamental in the sheet metal fabrication sector. These drawings are graphical representations of the final product, carrying comprehensive details about dimensions, material specifics, .

sheet metal dimensioning standards

This video demonstrates how to properly dimension a sheet metal layout technical drawing. It reviews general dimension standards as well as requirements for.Form angle, offset dimension and overall shape of emboss are all factors that impact manufacturability. Process by which metal currency is minted. Surface material is pressed. .In CAD drafting for sheet metal fabrication, dimensioning involves precisely annotating the size and location of features on 2D drawings or 3D models, crucial for part fit and function. This . Dimensioning a part in a drawing makes metal fabricating that part much easier. Our experts explain dimensioning and its role in drafting. Learn more here.

Dimensional accuracy, tolerance specifications, material specifications, surface finish, and welding symbols are five key metrics in sheet metal fabrication drawings, important for high standard product quality. These .A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points and show included bend angles.Generally, dimensioning should be done from a feature to an edge. Avoid feature-to-feature dimensions over two or more planes. Feature-to-bend dimensions may require special fixtures or gauging. This also means that tolerances in the title block .

requirements for sheet metal part drawings Sheet metal parts are typically created from material less than .250 inches thick, and are formed by folding the material at specific locations with a controlled bend radius.

Sheet metal drawings provide detailed dimensions, tolerances, and material requirements, helping manufacturers accurately understand design intent and produce products that meet specifications.

Two-dimensional (2D) drawings are fundamental in the sheet metal fabrication sector. These drawings are graphical representations of the final product, carrying comprehensive details about dimensions, material specifics, finish types, and other attributes. This video demonstrates how to properly dimension a sheet metal layout technical drawing. It reviews general dimension standards as well as requirements for.Form angle, offset dimension and overall shape of emboss are all factors that impact manufacturability. Process by which metal currency is minted. Surface material is pressed. Requires moderately priced tooling. Coined features are stamped in the wire crimp area while the part is in a flat state.In CAD drafting for sheet metal fabrication, dimensioning involves precisely annotating the size and location of features on 2D drawings or 3D models, crucial for part fit and function. This includes

Dimensioning a part in a drawing makes metal fabricating that part much easier. Our experts explain dimensioning and its role in drafting. Learn more here. Dimensional accuracy, tolerance specifications, material specifications, surface finish, and welding symbols are five key metrics in sheet metal fabrication drawings, important for high standard product quality. These metrics reduce errors and improve production efficiency.

A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points and show included bend angles.Generally, dimensioning should be done from a feature to an edge. Avoid feature-to-feature dimensions over two or more planes. Feature-to-bend dimensions may require special fixtures or gauging. This also means that tolerances in the title block . requirements for sheet metal part drawings Sheet metal parts are typically created from material less than .250 inches thick, and are formed by folding the material at specific locations with a controlled bend radius. Sheet metal drawings provide detailed dimensions, tolerances, and material requirements, helping manufacturers accurately understand design intent and produce products that meet specifications.

commercial cnc machine

Two-dimensional (2D) drawings are fundamental in the sheet metal fabrication sector. These drawings are graphical representations of the final product, carrying comprehensive details about dimensions, material specifics, finish types, and other attributes.

This video demonstrates how to properly dimension a sheet metal layout technical drawing. It reviews general dimension standards as well as requirements for.Form angle, offset dimension and overall shape of emboss are all factors that impact manufacturability. Process by which metal currency is minted. Surface material is pressed. Requires moderately priced tooling. Coined features are stamped in the wire crimp area while the part is in a flat state.

In CAD drafting for sheet metal fabrication, dimensioning involves precisely annotating the size and location of features on 2D drawings or 3D models, crucial for part fit and function. This includes

sheet metal dimensioning guidelines

Dimensioning a part in a drawing makes metal fabricating that part much easier. Our experts explain dimensioning and its role in drafting. Learn more here.

sheet metal diagram fabrication

sheet metal design basics

New and used Corrugated Sheets for sale in West Columbia, South Carolina on Facebook Marketplace. Find great deals and sell your items for free.New and used Corrugated Sheets for sale near you on Facebook Marketplace. Find great deals or sell your items for free.

dimensioning sheet metal drawings|sheet metal drawing symbols