cnc lathe machining loss from chuckk holding A standard three draw chuck should hold a component concentric to about 0.003" after it's been turned around. Using a four jaw chuck and setting up correctly should enable .

Wendling Sheet Metal has vast experience in building and innovating custom sheet metal products to meet the unique needs of a wide variety of industrial customers.

0 · cnc machining chucking pressure

1 · cnc lathe working thumb rules

2 · cnc lathe working thumb

3 · cnc lathe work holding rules

4 · cnc lathe work holding instructions

5 · cnc lathe holding

6 · cnc lathe chucking pressure

7 · cnc chuck clamping force

Product is Ready to Operate out of the Box, Including Four Rear Mounting Holes, Mounting Feet, Wall Anchors, Hardware, and Wire Ties to Simplify Installation. Count on Zoeller® Pumps to deliver the very best solutions as the leading brand for pumps and pump accessories.

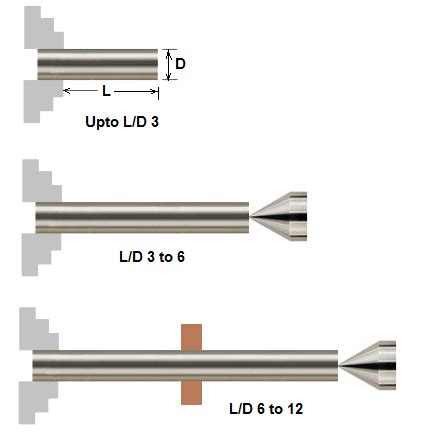

Here’s a CNC lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a steady, .

Im new to CNC (had used machine for three months now) and yesterday for the first time I noticed my workpiece was moving backwards into the chuck while roughing from time to . Put 1/3 or more of the workpiece into the chuck; If the workpiece has more than a 3-to-1 length-to-diameter ratio: Support the workpiece with a tailstock or steadyrest if you have . Workholding is a critical aspect of the CNC machining process as it directly impacts the quality, accuracy, and efficiency of the finished product. Proper workholding ensures that the workpiece does not move or deform .

There are many reasons, including less than stellar repeatability and runout along with an inability to clamp delicate parts. But the biggest reason is setup time: Even the fastest machinist needs about 10 minutes to change and rebore a . A standard three draw chuck should hold a component concentric to about 0.003" after it's been turned around. Using a four jaw chuck and setting up correctly should enable .We'll explore some key aspects of a chuck used on CNC machines, including its definition, working principle, parts, types as well as the difference between CNC and manual chuck. Here’s a CNC lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a steady, based on the L/D (Length to Diameter) ratio of the part. Chuck only: Use if L/D is less than 3.

Im new to CNC (had used machine for three months now) and yesterday for the first time I noticed my workpiece was moving backwards into the chuck while roughing from time to time.. The material was 35mm diameter 304 stainless, the chuck is a manual 3 jaw and Im tightening it with about a 12" long handle from the key axis. You must keep your chuck well lubricated, ideally with proper chuck grease, to have consistent grip and accuracy. The lower the chucking pressure the more care and attention you have to give to ensure safe chucking and operation. The chuck is an HWR Inoflex VK026. Right on the chuck it says 50KN max draw force and 130KN max clamp force. The pressure gages say 3.2MPa and the area of the hydraulic actuator is 103cm^2.

There are times when chucks and fixtures on CNC machines cannot adequately hold the machined piece. In this case, vibrations and shifting can occur which can spell big trouble for the production process. Our solutions are rudimentary, and usually involve an elevated approach to the problem. Put 1/3 or more of the workpiece into the chuck; If the workpiece has more than a 3-to-1 length-to-diameter ratio: Support the workpiece with a tailstock or steadyrest if you have this condition; Turning speed and holding force are related: as the speed increases, the holding force decreases. Workholding is a critical aspect of the CNC machining process as it directly impacts the quality, accuracy, and efficiency of the finished product. Proper workholding ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts.There are many reasons, including less than stellar repeatability and runout along with an inability to clamp delicate parts. But the biggest reason is setup time: Even the fastest machinist needs about 10 minutes to change and rebore a set of top jaws.

A standard three draw chuck should hold a component concentric to about 0.003" after it's been turned around. Using a four jaw chuck and setting up correctly should enable you to get within about 0.001" for the same procedure. “Do not worry about your problems with mathematics, I assure you mine are far greater.” Albert Einstein

We'll explore some key aspects of a chuck used on CNC machines, including its definition, working principle, parts, types as well as the difference between CNC and manual chuck. Here’s a CNC lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a steady, based on the L/D (Length to Diameter) ratio of the part. Chuck only: Use if L/D is less than 3. Im new to CNC (had used machine for three months now) and yesterday for the first time I noticed my workpiece was moving backwards into the chuck while roughing from time to time.. The material was 35mm diameter 304 stainless, the chuck is a manual 3 jaw and Im tightening it with about a 12" long handle from the key axis.

cnc machining chucking pressure

You must keep your chuck well lubricated, ideally with proper chuck grease, to have consistent grip and accuracy. The lower the chucking pressure the more care and attention you have to give to ensure safe chucking and operation. The chuck is an HWR Inoflex VK026. Right on the chuck it says 50KN max draw force and 130KN max clamp force. The pressure gages say 3.2MPa and the area of the hydraulic actuator is 103cm^2.

There are times when chucks and fixtures on CNC machines cannot adequately hold the machined piece. In this case, vibrations and shifting can occur which can spell big trouble for the production process. Our solutions are rudimentary, and usually involve an elevated approach to the problem.

Put 1/3 or more of the workpiece into the chuck; If the workpiece has more than a 3-to-1 length-to-diameter ratio: Support the workpiece with a tailstock or steadyrest if you have this condition; Turning speed and holding force are related: as the speed increases, the holding force decreases. Workholding is a critical aspect of the CNC machining process as it directly impacts the quality, accuracy, and efficiency of the finished product. Proper workholding ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts.There are many reasons, including less than stellar repeatability and runout along with an inability to clamp delicate parts. But the biggest reason is setup time: Even the fastest machinist needs about 10 minutes to change and rebore a set of top jaws.

A standard three draw chuck should hold a component concentric to about 0.003" after it's been turned around. Using a four jaw chuck and setting up correctly should enable you to get within about 0.001" for the same procedure. “Do not worry about your problems with mathematics, I assure you mine are far greater.” Albert Einstein

cnc lathe working thumb rules

metal j shelf bracket

metal housing iphone 5

cnc lathe working thumb

To weld thin metal, choose an appropriate process (TIG or MIG with low amperage), use a smaller diameter wire or filler rod, and adjust travel speed to prevent burn-through. Employ a pulsing technique, stitch welding, or .

cnc lathe machining loss from chuckk holding|cnc lathe working thumb