width of laser beam used to cut sheet metal Sheet metal laser cutting is a fabrication process that uses a high-powered laser beam to precisely cut or engrave metal sheets. Controlled by a CNC system, the laser emits a focused beam of light that heats and melts the metal at targeted . You can make fabrics unique patterns by picking a weave design that combines the proportion of over and under threads. Therefore, it’s possible to create interesting patterns in fabric by utilizing strands of various colors and then selecting which threads display on top of each other similarly.

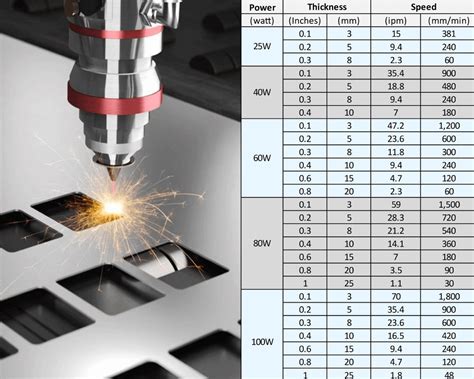

0 · laser cutting thickness

1 · laser cutting speed chart pdf

2 · laser cutting sheet metal

3 · laser cutting efficiency chart

4 · fiber laser cutting speed

Standards: Steel: EN 10130, GOST 16523, GOST 1050: Dimensions and .

The fiber laser cutting system is known for its speed and precision, and typically, fiber lasers are utilized via the following process. In a fiber laser cutting machine, banks of diodes are used to create a laser beam that is . It uses high-power laser beams to cut sheet metal into exact specifications. The cutting technique uses an adjusted focus light and an assist gas. The light and gas typically .

Sheet metal laser cutting is a fabrication process that uses a high-powered laser beam to precisely cut or engrave metal sheets. Controlled by a CNC system, the laser emits a focused beam of light that heats and melts the metal at targeted .In layman's terms, sheet metal laser cutting is a process where a high-powered laser beam is used to cut, engrave, or shape metal sheets. This method stands out for its precision, speed, and flexibility, making it a go-to choice for various .

It involves using high-power laser beams that are focused and adjusted to cut sheet metal into specific sizes and shapes. An assist gas is combined with the laser beam to burn the metal into the desired shape or size.Sheet metal laser cutting harnesses the power of concentrated light to cut through metal precisely and efficiently. Read on to discover how sheet metal laser cutting is indispensable to the automotive, aerospace, and electronic industries.

Understanding the technology and importance of laser cutting in precision sheet metal fabrication. Advantages of laser cutting, including reduced material contamination and enhanced stability. Types of lasers used, materials . Laser cutting works by focusing a laser beam onto a specific point on the sheet metal parts, which melts or vaporizes the material. This process is guided by a computer-controlled machine that follows a predetermined cutting .

11 Resources. What is Laser Cutting Sheet Metal? Laser cutting sheet metal is a subtractive manufacturing process used to precisely cut and shape sophisticated metal parts.

Cutting seam width: mm: 0.1: 0.1: 0.12: 0.12: 0.12: 0.12: 0.12: Lens focal length: inch: 5: 5: 5: 5: 5: 5: 7.5: Focal point position-0.5-1-2: 3 . Ever wondered why laser-cut sheet metal sometimes falls short of perfection? This . That’s the marching order for beam manipulation employed in the world of laser cutting and welding. For its part, Trumpf offers beam-shaping technology unique to the processes of 3D laser cutting, 3D laser welding and . The laser beam is directed onto the metal sheet or other material with intense heat to create the desired cut parts. . The laser cut width can typically be less than 0.001 inch. On the other hand, the laser cut dimensional . The material being cut; he power of the laser being used to make a cut will impact kerf width. Generally speaking, higher power levels result in wider kerf widths, and lower power levels result in narrower kerf widths. As well as this, the focal length and diameter of the laser beam is another important factor impacting kerf width.

Sheet Metal Laser Cutting Benefit #1: Precision. The precision of sheet metal laser cutting allows us to create intricate designs with few errors. The laser beam makes accurate cuts and creates high-quality finished products with infinitely repeatable dimensions. Sheet Metal Laser Cutting Benefit #2: Versatility. Sheet metal laser cutting is .

2002 ford taurus power distribution fuse box

laser cutting thickness

As a result, material thicknesses from 0.05 up to 0.5 mm for many metal materials used in industry can be remote cut by means of single mode fiber laser with final velocities between 50 and 1000 m/min. Fig. 8 shows the resulting cutting speed for different laser power and identical focus size for a single path speed of 1000 m/min as a function . The size of laser cutting tolerances determines whether the parts can meet design requirements and fit accurately with other parts. Laser Cutting Tolerance Standard. . and the quality of the laser beam. Here is a general guideline for laser cutting tolerances. . Sheet Metal: Up to 12 ga (2.5mm) +/- 0.005″ (0.13mm) Sheet Metal:

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece. . As the name suggests, sheet metal laser cutting machines are mainly used to process various types of metal sheets. This type of sheet metal cutting machine is mainly used in the sheet metal industry. The tube laser cutting . A: A powerful laser beam is directed towards the sheet metal when cutting sheet metal. The light beam melts or vaporizes the metal, and then a gas blast removes the molten material to create an accurate, clean cut. Baison High Power Sheet Metal Laser Cutting Machine: With its high-powered laser beam, High Power Sheet Metal Laser Cutting Machine stands out in terms of efficiency and productivity. It can handle thick titanium sheets effortlessly while maintaining excellent cut quality. Make you a leader in your industry with our high-power sheet metal laser .

Laser cutting is a technology that uses a focused laser beam to cut through materials. The laser beam is generated by a laser source and directed through a series of mirrors or fiber optics to the laser head. The laser head contains a lens that focuses the laser beam to a small spot size, increasing its intensity.

Sheet Metal Laser Cutting Processes All of the above laser cutting machines use the power of laser beams to cut metal sheets into metal parts. Therefore, the laser cutting process essentially has two interworking components occurring at once. In one method, the sheet metal material absorbs the focused laser beam, which causes the cut.What is Sheet Metal Laser Cutting? Sheet metal laser cutting is a fabrication process that uses a high-powered laser beam to precisely cut or engrave metal sheets. Controlled by a CNC system, the laser emits a focused beam of light that heats and melts the metal at targeted locations, allowing for clean and intricate cuts or shapes.Metal laser cutting is the process whereby a focussed laser beam melts metal to cut it into the desired shape — using CNC (computer numerical control) and a high-powered laser. Enquire Now The high-powered laser beam used for laser cutting uses a motion control system that follows a pattern to cut out a predetermined pattern.

What is laser cutting? A laser beam is a concentrated beam of light, often focusing up to 15 kw of power onto an area a few millimeters in diameter. . Size: Knowing the maximum sheet size, as well as the bed size . Also, when a set of laser beam power, the velocity of the cutting, the pressure of the assist gas, and the focal point are used as an input parameters to machine a set of different steel alloys to investigate their effect on the roughness of the cut surface, it has been found that the high quality of cutting happens at 0.7–0.8 mm of sheet .

Explore our guide on how to cut steel sheet metal precisely with laser cutting technology. Learn from experts and achieve perfect results. (877) 553-2610 . Once the laser cutting machine is ready to cut sheet metal, the process begins. The laser beam is highly focused and concentrates on the area of the sheet metal that needs to be cut or .

In this article, we will delve into the various aspects through which fiber laser sheet cutting machines enhance precision and speed. Focused Laser Beam for Unparalleled Precision. Fiber lasers emit a highly concentrated and focused beam, resulting in a smaller kerf width (the width of the cut).At MetalsCut4U we use a laser cutter to cut the sheet metal parts you configure online. To cut sheet metal using a laser, a focused laser beam is directed at the material, which is then either melted, burned, vaporized, or blown away by a jet of gas. This cutting method leaves a sleek edge with a high quality and smooth finish.

laser cutting speed chart pdf

2. Benefits of Sheet Metal Laser Cutting. Sheet metal laser cutting is a popular method in manufacturing due to its precision and efficiency. It offers numerous advantages that make it a preferred choice for many projects. Here are some key benefits: Increased Efficiency. Sheet metal laser cutting speeds up the production process significantly. Harder materials, such as stainless steel, require higher laser power and slower cutting speeds to achieve clean cuts. Factors Influencing Accuracy. Laser Power Stability: Fluctuations in laser power can affect the accuracy of the cuts. Consistent and stable laser power ensures uniform cutting depth and width throughout the process.In layman's terms, sheet metal laser cutting is a process where a high-powered laser beam is used to cut, engrave, or shape metal sheets. This method stands out for its precision, speed, and flexibility, making it a go-to choice for various industries, including automotive, aerospace, and electronics. . The art of sheet metal laser cutting is .

Sheet metal laser cutting involves using a high-powered laser beam to cut sheet metal. Firstly, the laser cutter for metal or plastic is programmed with the desired cut pattern and positions the sheet metal into the cutting area. Subsequently, the laser emits a beam of light that heats the sheet metal to its melting point and vaporizes it. Then . It uses high-power laser beams to cut sheet metal into exact specifications. The cutting technique uses an adjusted focus light and an assist gas. The light and gas typically burn any metal into the desired shape or size. A laser cutter with a power rating of a few kilowatts (1-12kW) is recommended for industrial sheet-metal cutting applications. However, a 500W laser can be used for cutting thin metal workpieces for low-volume projects. Laser cutting is a quick and effective way of producing clean cuts in thin metal sheets. The precise movement of the laser beam is controlled by computer-aided design (CAD) software, allowing for intricate cuts and complex shapes to be effortlessly achieved. Types of Sheet Metal Laser Cutting Machines. . Sheet metal laser cutting machines can process a wide variety of metals, including steel, stainless steel, and aluminum.

The work concerns the numerical analysis of the laser cutting process of sheet made of steel. The influence of selected parameters on the . For all cases, the same laser beam power is used in the cutting process. The other parameters are chosen to obtain a good quality of cut [3, 9]. . where the comparative criterion is the width of the cut .

2001 maxima sheet metal

s, (kg/m), where ρ is the flatness of steel 7850 kg/m³; s - metal thickness; in mm; a - .

width of laser beam used to cut sheet metal|laser cutting sheet metal