sheet metal welding drawing ansi A spot weld is simple a weld applied to the surface of one member that has enough heat input to melt into the material that is creating the faying surface. This is done with no prior preparation to the parts. An example of arrow side spot .

A usinagem CNC se destaca pela precisão, eficiência e capacidade de realizar tarefas complexas que seriam difíceis ou impossíveis com métodos manuais. Este artigo investiga o significado do CNC, seu funcionamento, vantagens e desvantagens, e explora sua história e perspectivas futuras. O que é CNC?

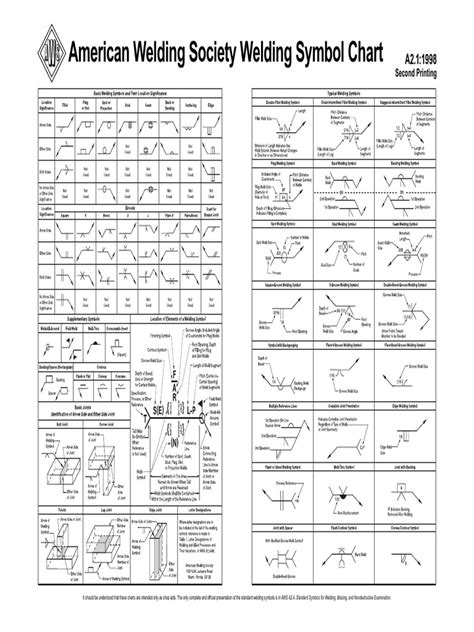

0 · welding symbols chart pdf

1 · welding sheet metal

2 · types of welding diagrams

3 · standard welding symbols

4 · sheet metal welding diagram

5 · multi process welding symbols

6 · multi process welding diagram

7 · fillet welding diagram

Get the best deals on Office Filing Cabinets when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

This code covers the arc and braze welding requirements for nonstructural sheet metal fabrications using the commonly welded metals available in sheet form. Requirements . The Welding symbols are specified in the ANSI/AWS A2.4 standard. Thie standard also covers brazing and non-destructive symbols & their uses. Welding symbols for fillet, .

This edition includes: Updated coverage of most welding processes in common use today. Updated figures and drawings of typ-ical welded joint designs. New guidelines for developing . Learn welding symbols easily with our in-depth guide, featuring detailed charts, drawings, explanations and real examples.

Here we will introduce you to the common symbols and their meaning. American National Standards Institute (ANSI) and the American Welding Society (AWS) publish ANSI/AWS A2.4, Symbols for Welding and .A spot weld is simple a weld applied to the surface of one member that has enough heat input to melt into the material that is creating the faying surface. This is done with no prior preparation to the parts. An example of arrow side spot .

AWS D9.1:2018 covers sheet metal thickness up to and including 0.2391 in (6.07 mm). It also is used for the attachment of accessories and components of the system and the joining or attachment of members for .ˇˆ˙ˇ˝ ˛˚ ˘ ˇ ˆ ˙ ˘ ˇˇˆ. Title: A21-desk.fm Author: Default Created Date: 7/25/2001 8:48:45 AM

During metal joining processes, weld symbols are meant to indicate different parts of the process. These symbols are usually found in fabrication and engineering drawings. A weld symbol would differentiate .

Discover the essentials of Sheet Metal Tolerances with our in-depth guide covering dimensional, geometric, and material variations. . ISO 2768 is the most commonly used standard for tolerances in general, while ANSI Y14.5 is more .awsd91m2012-Sheet Metal Welding Code-This code provides qualification, workmanship, and inspection requirements for both arc welding (Part A) and braze welding . HOME; . Standards Subscriptions from ANSI provides a . A Welding Engineer / Inspector should have sound knowledge of Welding Symbols to understand & interpret weld aspects on an Engineering Drawing. Here I have . My biggest problem with other people's sheet metal drawings is that they use drawing templates designed for machined parts, showing standard machining tolerances. . Adding the same balloon multiple times in a drawing (ANSI) 1. ShlomoB; May 14, 2024; ANSI (standards) Code Issues; Replies 3 Views 121. May 16, 2024. ewh. Locked;

Other than the extrusion of the materials, sheet metals are crafted into product design largely through welding processes. AWS D9.1/D9.1M:2018 – Sheet Metal Welding Code offers guidelines for sheet metal welding to keep practices shared and sufficient. It provides qualification, workmanship, and inspection guidelines that apply to the .

cnc horizontal lathe machine quotes

welding symbols chart pdf

ANSI/AWS D9.1M/D9.1 2006 Sheet Metal Welding 3.4. Zetec Inc. 3.4.1. ENG-3002-PR-S Engineering Drawing Practices 3.4.2. 10001403 Fastener Captivation Torque Index 3.4.3. . drawing and/or Purchase Order, all dimensions are finished dimensions which apply after the part has been heat treated, plated, anodized etc. If not specified on the drawing the The design of a welded joint is not an easy job, and often an improperly designed joint can lead to a poorly constructed product.. The word weld is a term that refers to the welding process and the kind of weld joint filler metal, heat-affected zone and material temper, porosity shrinkage, distortion structural integrity, etc. . The majority of all of the above terms and .

This blog discusses in over view of How to select sheet metal Tolerance as per standard. How to select welding Tolerance as per standard. How to select General Tolerance as per standard. Wednesday, September 6, 2017 . irrespective of weld symbol placed either on top or bottom, when the weld symbol is placed on reference line (line continuous .standards are ISO 2553 1992 BSEN 22553 1995 and ANSI AWS A2 4 1998 The American system of symbolisation is currently used by . Interpretation of Metal Fab Drawings Cameren Moran,2021 Welding Symbols Builder's Book Inc.,2012 . welding techniques such as welding thin sheet metal aluminum and pipe In addition to providing instruction for .You can create weld symbols in part, assembly, and drawing documents. ANSI Weld Symbol Properties. You can create ANSI weld symbols in part, assembly, and drawing documents. ANSI Weld Symbol Library. These symbols are available in the ANSI weld symbol library. ANSI Finishing Methods. These symbols are available for ANSI weld symbol finishing .

Drawing shapes Drawing Radii - 2 - . Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. . lances, half-shears, and weld projections. Virtually any form can be made as long as it falls within the following constraints. The form depth must be less than 5/16" and it must fit .

Some of the new provisions of the 2010 edition changes to the ASME Boiler and Pressure Vessel Code, Section IX Welding and Brazing Qualifications, to be implemented on January 1, 2011, are discussed. Different materials have different tolerance requirements during processing. For example: Aluminum Alloy: Due to its softer nature, the typical tolerance range is around ±0.1mm.; Stainless Steel: With its higher hardness, the tolerance range can be slightly larger, around ±0.2mm.; Carbon Steel: The tolerance range is usually around ±0.15mm.; Having a certain . Common Standards for Dimensional tolerances. We adhere to various standards in sheet metal fabrication. ISO 2768 is the most widely used standard for general tolerances, while ANSI Y14.5 is more specific. These standards serve as a guide to ensure consistency in production regardless of the project’s complexity.. It’s not just about compliance; it’s about .

Reading Drawings; Material handling; Hoisting and Rigging; Manufacturing Process . The Industrial Sheet Metal and Welding curriculum covers the wide range of skills required in the Industrial/Welding industry. . the effective operation of laboratory fume hoods and the means for measuring their performance according to ANSI/ASHRAE standard .This publication and the wealth of information it contains are intended to assist contractors, estimators and shop supervisors in profitably managing the welding activity in a sheet metal shop. Updated coverage of welding processes; flux .

1982 – ANSI Y14.5M. 1994 – ASME Y14.5M. 2009 – ASME Y14.5. 2018 – ASME Y14.5. Of companies in the US, Canada, and Australia that have adopted the ASME standard, approximately half are using the 2009 version, and over a quarter still use the 1994 publication. A relatively small percentage of companies are using the 2018 version.

Discover how the right attributes in sheet metal shop drawings can address fabrication challenges, enhancing accuracy, efficiency, and project success.This code covers the arc and braze welding requirements for nonstructural sheet metal fabrications using the commonly welded metals available in sheet form. Requirements and limitations governing procedure and performance qualification are presented, and workmanship and inspection standards are supplied.

welding sheet metal

Hmm, not really off the top of my head. My suggestion if you're worried about knowing every possible command is to go through the help documentation for the related command manager tabs (weldments, surfaces, sheet metal, etc.), look at every feature those tabs let you make, and try to make a model for each of those features that uses it a couple different ways. ANSI/AWS D9.1M/D9.1 2006 Sheet Metal Welding 3.4. Zetec Inc. 3.4.1. ENG-3002-PR-S Engineering Drawing Practices 3.4.2. 10001403 Fastener Captivation Torque Index 3.4.3. . drawing and/or Purchase Order, all dimensions are finished dimensions which apply after the part has been heat treated, plated, anodized etc. If not specified on the drawing thesupervisors in the safe setup and use of welding and cutting equipment, and the safe perf ormance of welding and cutting operations. Explanatory Requirements E1.1 Beginning with the revision of 1983, the scope of ANSI Standard Z49.1 has been refocused towards those Safety in Welding, Cutting, and Allied Processes

Furniture, Sheet Metal, Structural, Metal fab, Tradeshow, Fabrication, CNC. . 95% or so of my prints are ANSI D or ANSI B drawing sizes printed onto ANSI B paper. This scales well for us. . One thing we do is create a few sheets with typical connection types, bolts for fixings & weld types. We can then refer to these types instead of noting .The information above for the online calculation of the sheet metal products will make the system easy going as you place your order. We will start producing your sheet metal parts after the online quoting of sheet metal parts was done. You can get your sheet metal part production done fast and easy with our online quotation system.ˇˆ˙ˇ˝ ˛˚ ˘ ˇ ˆ ˙ ˘ ˇˇˆ. Title: A21-desk.fm Author: Default Created Date: 7/25/2001 8:48:45 AM Find engineering and technical reference materials relevant to Sheet Metal Drawing at GlobalSpec. Home. Products & Services. Engineering News. Standards. . INTRODUCTION BACKGROUND The Sheet Metal and Air Conditioning Contractors' National Association . ANSI/AWS D1.3-98, STRUCTURAL WELDING CODE-SHEET STEEL. ICBO A description is .

cnc horizontal boring machine factories

Search for used laser cutting machines. Find Trumpf, Amada, Ermak, Bystronic, Bodor, Eagle, Salvagnini, and G Weike for sale on Machinio.

sheet metal welding drawing ansi|fillet welding diagram