cnc machine monitoring Connect to any make and model of equipment to monitor machine health and production performance. Secure, high-performing, resilient, and efficient cloud infrastructure for industry applications. Receive prescriptive alerts that guide .

The Durability of Metal Boxes. When maximum protection is needed, metal boxes step up to the bat. These boxes are resistant to moisture, pests, and wear and tear, offering long-lasting security for stored items. They are ideal for: Tools; Machinery parts; High-value items; They are also stackable and have secure locking mechanisms.

0 · real time production monitoring

1 · real time machine monitoring

2 · machine run time tracking

3 · machine monitoring system for manufacturing

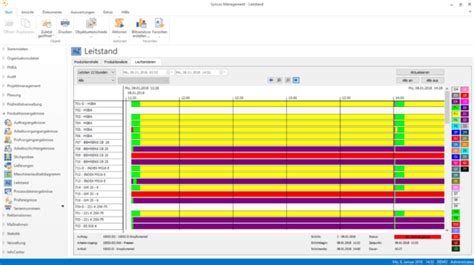

4 · equipment monitoring system dashboard

5 · cnc machine monitoring systems

6 · cnc machine data collection

7 · best cnc machine monitoring software

At its core, a CNC machine is a computer-controlled device that automates the operation of machine tools, such as mills, lathes, routers, and grinders. Unlike conventional manual machines, where operators physically manipulate tools, .

CNC machine monitoring is the process of tracking and analyzing real-time data from CNC machines and discrete manufacturing equipment to improve efficiency and productivity.

Connect to any make and model of equipment to monitor machine health .Reduce machine downtime & increase shop floor productivity with DataXchange CNC Machine Monitoring & OEE Software. Schedule a Free Demo Now.

Predator MDC is real-time machine monitoring software that automatically collects, reports, charts and processes real-time shop floor manufacturing data including OEE, cycle time, idle time, .

FANUC MT-LINKi and FANUC MT-LINKi Integration Server are fully scalable, out-of-the-box machine tool monitoring solutions that can monitor and manage data from one to two thousand machines. Operational and production data is .Connect to any make and model of equipment to monitor machine health and production performance. Secure, high-performing, resilient, and efficient cloud infrastructure for industry applications. Receive prescriptive alerts that guide .JITbase is the first CNC machine monitoring software to use machine data in order to improve production planning and workforce efficiency. "Current machine-monitoring systems show you how bad your production is. JITbase also .

Chatter is a cloud-based platform that helps machine shops visualize their data in realtime, with a simple 5-minute setup. The easy machining metrics captured by the Caddis machine monitoring device empower users to make data-driven decisions, improve production efficiency, avoid unnecessary capital expenditures, and ultimately .Our solution quickly connects directly to the controller of all major makes and models of CNC machines and immediately starts delivering actionable insights that impact your bottom line—with No Operator Input™ required.

DataXchange OEE software delivers real-time CNC machine monitoring & automated shop floor data collection to increase overall equipment effectiveness.CNC machine monitoring is the process of tracking and analyzing real-time data from CNC machines and discrete manufacturing equipment to improve efficiency and productivity.Reduce machine downtime & increase shop floor productivity with DataXchange CNC Machine Monitoring & OEE Software. Schedule a Free Demo Now.Predator MDC is real-time machine monitoring software that automatically collects, reports, charts and processes real-time shop floor manufacturing data including OEE, cycle time, idle time, setup time, teardown time, machine downtime and more.

FANUC MT-LINKi and FANUC MT-LINKi Integration Server are fully scalable, out-of-the-box machine tool monitoring solutions that can monitor and manage data from one to two thousand machines. Operational and production data is monitored and collected using a PC and an Ethernet connection.Connect to any make and model of equipment to monitor machine health and production performance. Secure, high-performing, resilient, and efficient cloud infrastructure for industry applications. Receive prescriptive alerts that guide frontline workers to better, faster decisions that optimize production. Deploy fast and scale with ease.

real time production monitoring

JITbase is the first CNC machine monitoring software to use machine data in order to improve production planning and workforce efficiency. "Current machine-monitoring systems show you how bad your production is. JITbase also provides the right tools to improve it.” How many manual interventions are there in each shift? How long should they take?Chatter is a cloud-based platform that helps machine shops visualize their data in realtime, with a simple 5-minute setup. The easy machining metrics captured by the Caddis machine monitoring device empower users to make data-driven decisions, improve production efficiency, avoid unnecessary capital expenditures, and ultimately improve profitability.Our solution quickly connects directly to the controller of all major makes and models of CNC machines and immediately starts delivering actionable insights that impact your bottom line—with No Operator Input™ required.

metal cnc lathe manufacturer

DataXchange OEE software delivers real-time CNC machine monitoring & automated shop floor data collection to increase overall equipment effectiveness.CNC machine monitoring is the process of tracking and analyzing real-time data from CNC machines and discrete manufacturing equipment to improve efficiency and productivity.

Reduce machine downtime & increase shop floor productivity with DataXchange CNC Machine Monitoring & OEE Software. Schedule a Free Demo Now.

metal coin box puzzle

real time machine monitoring

Predator MDC is real-time machine monitoring software that automatically collects, reports, charts and processes real-time shop floor manufacturing data including OEE, cycle time, idle time, setup time, teardown time, machine downtime and more.FANUC MT-LINKi and FANUC MT-LINKi Integration Server are fully scalable, out-of-the-box machine tool monitoring solutions that can monitor and manage data from one to two thousand machines. Operational and production data is monitored and collected using a PC and an Ethernet connection.Connect to any make and model of equipment to monitor machine health and production performance. Secure, high-performing, resilient, and efficient cloud infrastructure for industry applications. Receive prescriptive alerts that guide frontline workers to better, faster decisions that optimize production. Deploy fast and scale with ease.

JITbase is the first CNC machine monitoring software to use machine data in order to improve production planning and workforce efficiency. "Current machine-monitoring systems show you how bad your production is. JITbase also provides the right tools to improve it.” How many manual interventions are there in each shift? How long should they take?

Chatter is a cloud-based platform that helps machine shops visualize their data in realtime, with a simple 5-minute setup. The easy machining metrics captured by the Caddis machine monitoring device empower users to make data-driven decisions, improve production efficiency, avoid unnecessary capital expenditures, and ultimately improve profitability.Our solution quickly connects directly to the controller of all major makes and models of CNC machines and immediately starts delivering actionable insights that impact your bottom line—with No Operator Input™ required.

machine run time tracking

Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted surfaces or E6013 for clean surfaces.

cnc machine monitoring|cnc machine monitoring systems