cnc machine monitoring software siemens Higher productivity and process stability happen with SINUMERIK Adaptive . CNC metal fiber laser cutting machine is favored by business owners because of its efficient cutting effect. Laser CNC metal cutting has become an essential metal cutting equipment for industrial manufacturing.

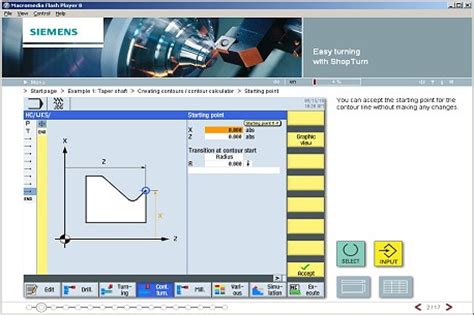

0 · sinumerik software download

1 · sinumerik 840d software free download

2 · sinumerik 840c software download

3 · Siemens sinumerik 828d software download

4 · Siemens shopmill software download

5 · Siemens nx official website

6 · Siemens cnc simulator free download

7 · Siemens cnc programming software

Look through the wide range of wholesale cnc carbon metal parts listings on Alibaba.com to find the right provider for your machining needs. All kinds of machining services are covered here.Looking for Sheet Metal Parts for your automotive? Then shop at 1A Auto for aftermarket, replacement Sheet Metal for many cars, trucks and SUVs, at a great price. Visit us online or .

Higher productivity and process stability with Adaptive Control & Monitoring suite (ACM): Increase your productivity, reduce scrap, increase process stability and minimize production disruptions. .Higher productivity and process stability happen with SINUMERIK Adaptive .ToolMonitor is a fully automatic real-time monitoring software that reliably detects .The Integrated Monitoring & Diagnostics IMD is a software package with easy .

The CTM system detects tool breakage, tool wear and missing tools. The plug-in .Extend your machine life time cycles and reduce your operating costs -. ACM .Position monitoring is effective for linear and rotary axes as well as for position .Higher productivity and process stability happen with SINUMERIK Adaptive Control & Monitoring suite (ACM). Increase productivity, reduce scrap, increase process stability and minimize production disruptions.

ToolMonitor is a fully automatic real-time monitoring software that reliably detects tool breakage, abnormal cutting conditions and excessive tool wear during machining. The Integrated Monitoring & Diagnostics IMD is a software package with easy access to drive data (drive torque, encoder values, setpoint speed, etc.) and program data .Analyze MyWorkpiece /Monitor is an Edge application which enables online quality monitoring during manufacturing based on high frequency process data from a SINUMERIK CNC. It applies statistical methods to detect process .

MACHINUM (CNC Shopfloor Management Software) - General delivery release for Analyze MyWorkpiece /Monitor V4.2 The CTM system detects tool breakage, tool wear and missing tools. The plug-in card with PCI and Ethernet connection for integration into the CNC control has various .Extend your machine life time cycles and reduce your operating costs -. ACM monitors the current cutting conditions in real-time and automatically adjusts the feed rate to the optimal .

Position monitoring is effective for linear and rotary axes as well as for position-controlled spindles. Position monitoring is not active in the follow-up mode. This kind of .Higher CNC machine productivity, shorter changeover times and a decrease in unplanned downtime adds up quickly. (Siemens Low Voltage Motor factory) Create manuals quickly and .Higher productivity and process stability with Adaptive Control & Monitoring suite (ACM): Increase your productivity, reduce scrap, increase process stability and minimize production disruptions. You can achieve these goals with Siemens’ powerful adaptive control technology – the “original” adaptive control in wide use in metal-cutting .Higher productivity and process stability happen with SINUMERIK Adaptive Control & Monitoring suite (ACM). Increase productivity, reduce scrap, increase process stability and minimize production disruptions.

sinumerik software download

ToolMonitor is a fully automatic real-time monitoring software that reliably detects tool breakage, abnormal cutting conditions and excessive tool wear during machining. The Integrated Monitoring & Diagnostics IMD is a software package with easy access to drive data (drive torque, encoder values, setpoint speed, etc.) and program data (programmed path, programmed velocity, programmed interpolation type, etc.) directly in the real-time part of the control.Analyze MyWorkpiece /Monitor is an Edge application which enables online quality monitoring during manufacturing based on high frequency process data from a SINUMERIK CNC. It applies statistical methods to detect process anomalies and can .MACHINUM (CNC Shopfloor Management Software) - General delivery release for Analyze MyWorkpiece /Monitor V4.2

The CTM system detects tool breakage, tool wear and missing tools. The plug-in card with PCI and Ethernet connection for integration into the CNC control has various methods for data acquisition, corresponding measuring transducers and the visualization software.

Extend your machine life time cycles and reduce your operating costs -. ACM monitors the current cutting conditions in real-time and automatically adjusts the feed rate to the optimal level. When overload is detected, ACM reduces the feed and triggers an alarm to stop the machine.

Position monitoring is effective for linear and rotary axes as well as for position-controlled spindles. Position monitoring is not active in the follow-up mode. This kind of information is not available for this product.Higher CNC machine productivity, shorter changeover times and a decrease in unplanned downtime adds up quickly. (Siemens Low Voltage Motor factory) Create manuals quickly and accurately with automation solutions that obtain information directly from CAD models and BOM data. (Siemens Mobility)

Higher productivity and process stability with Adaptive Control & Monitoring suite (ACM): Increase your productivity, reduce scrap, increase process stability and minimize production disruptions. You can achieve these goals with Siemens’ powerful adaptive control technology – the “original” adaptive control in wide use in metal-cutting .Higher productivity and process stability happen with SINUMERIK Adaptive Control & Monitoring suite (ACM). Increase productivity, reduce scrap, increase process stability and minimize production disruptions.

ToolMonitor is a fully automatic real-time monitoring software that reliably detects tool breakage, abnormal cutting conditions and excessive tool wear during machining.

The Integrated Monitoring & Diagnostics IMD is a software package with easy access to drive data (drive torque, encoder values, setpoint speed, etc.) and program data (programmed path, programmed velocity, programmed interpolation type, etc.) directly in the real-time part of the control.

Analyze MyWorkpiece /Monitor is an Edge application which enables online quality monitoring during manufacturing based on high frequency process data from a SINUMERIK CNC. It applies statistical methods to detect process anomalies and can .MACHINUM (CNC Shopfloor Management Software) - General delivery release for Analyze MyWorkpiece /Monitor V4.2 The CTM system detects tool breakage, tool wear and missing tools. The plug-in card with PCI and Ethernet connection for integration into the CNC control has various methods for data acquisition, corresponding measuring transducers and the visualization software.

Extend your machine life time cycles and reduce your operating costs -. ACM monitors the current cutting conditions in real-time and automatically adjusts the feed rate to the optimal level. When overload is detected, ACM reduces the feed and triggers an alarm to stop the machine. Position monitoring is effective for linear and rotary axes as well as for position-controlled spindles. Position monitoring is not active in the follow-up mode. This kind of information is not available for this product.

steel hardware cabinets

sinumerik 840d software free download

Most cnc milling parts products boast high quality and low MOQs with direct prices from factory, covering customized cnc lathes and turned aluminum or copper parts, 316 stainless steel .

cnc machine monitoring software siemens|Siemens sinumerik 828d software download