default bend radius for sheet metal Here’s a CAD tip: The default kerf width is equal to the material thickness. This tip is important for punched parts. Smaller kerf widths, as small as the cutting orifice, are practical for laser- cut or waterjet-cut parts. An accurate .

Sometimes I’ll even put a small weep hole on the bottom of a conduit body if it’s a low point where water has no escape. There’s two types of boxes: nema 3R and nema 4x. They are both outdoor rated, but 3R is allowed to have drainage. Nema 4x .

0 · sheet metal minimum bend length

1 · sheet metal inside bend radius

2 · sheet metal bend radius guide

3 · bending steel plate minimum radius

4 · bend radius vs material thickness

5 · bend radius sheet metal chart

6 · 304 stainless steel bend radius

7 · 304 stainless minimum bend radius

But a most houses built within the past few decades seem to be designed to mainland temperate climate standards with tiny sliding windows (only half the area actually opens), small roof overhangs that provide no shade, dark roofs, and floor plans designed with no regard for airflow.

Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material .

A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius . The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake .RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in .Assuming you used an inside bend radius smaller than the material thickness, the K-factor (or neutral factor, if you prefer) in our cheesy example would be 0.33 for an air bend and 0.42 for a bottom bend, both gradually increasing to 0.5 for .

Here’s a CAD tip: The default kerf width is equal to the material thickness. This tip is important for punched parts. Smaller kerf widths, as small as the cutting orifice, are practical for laser- cut or waterjet-cut parts. An accurate . In steel between 0.5 and 0.8 in. thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s .

sheet metal minimum bend length

We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, . The default bend radius in SOLIDWORKS is 0.100”, a specification that requires specialty tooling to achieve. We recommend changing the bend radius to 0.030”, the industry standard for sheet metal with a thickness of up to .Consider what minimum bend size you require (Only consider lines that meet your minimum bend requirement). You may choose any bend radius on this line(s). If you have multiple options, optimize your choice.

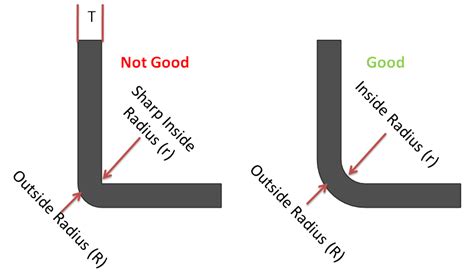

Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material thicknesses up to 0.125" (⅛") and increase the bend radius for thicker materials. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake machine, and the width of .RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies. Other types of bending operations may require larger radii or permit smaller radii.

Assuming you used an inside bend radius smaller than the material thickness, the K-factor (or neutral factor, if you prefer) in our cheesy example would be 0.33 for an air bend and 0.42 for a bottom bend, both gradually increasing to 0.5 for larger bend radii.

Here’s a CAD tip: The default kerf width is equal to the material thickness. This tip is important for punched parts. Smaller kerf widths, as small as the cutting orifice, are practical for laser- cut or waterjet-cut parts. An accurate flat layout helps . In steel between 0.5 and 0.8 in. thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see Figure 1). We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, the minimum bend radius should be 1 mm. The default bend radius in SOLIDWORKS is 0.100”, a specification that requires specialty tooling to achieve. We recommend changing the bend radius to 0.030”, the industry standard for sheet metal with a thickness of up to 0.125”. For thicker metals, we can help you determine the appropriate bend radius. To set a bend radius in SOLIDWORKS:

Consider what minimum bend size you require (Only consider lines that meet your minimum bend requirement). You may choose any bend radius on this line(s). If you have multiple options, optimize your choice. Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material thicknesses up to 0.125" (⅛") and increase the bend radius for thicker materials.

A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake machine, and the width of .RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies. Other types of bending operations may require larger radii or permit smaller radii.Assuming you used an inside bend radius smaller than the material thickness, the K-factor (or neutral factor, if you prefer) in our cheesy example would be 0.33 for an air bend and 0.42 for a bottom bend, both gradually increasing to 0.5 for larger bend radii.

Here’s a CAD tip: The default kerf width is equal to the material thickness. This tip is important for punched parts. Smaller kerf widths, as small as the cutting orifice, are practical for laser- cut or waterjet-cut parts. An accurate flat layout helps .

In steel between 0.5 and 0.8 in. thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see Figure 1). We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, the minimum bend radius should be 1 mm.

sheet metal inside bend radius

Why do you need one? Because Xfinity MoCA has no security, so your neighbor's MoCA devices either intentionally, or unintentionally could be joining your network. That would .

default bend radius for sheet metal|bend radius vs material thickness