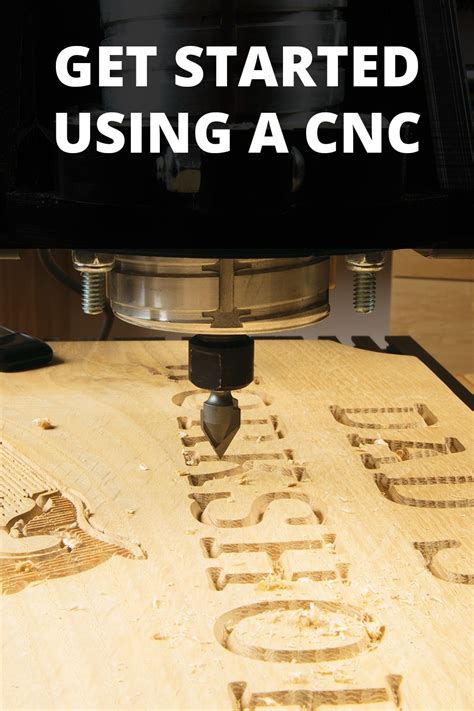

design cnc machine CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, . There are various uses of metal. But when it comes to recognizing metal arts, there are a few distinct centers in India that are known for their regional metal crafts. 1. Bidri Ware. The most popular is the Bidri ware of Andhra Pradesh.

0 · small cnc machine wood projects

1 · free cnc projects for beginners

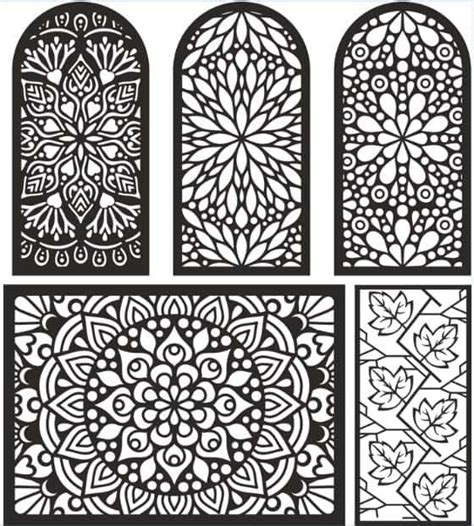

2 · free cnc patterns for wood

3 · cnc machine design pdf

4 · cnc machine design ideas

5 · cnc machine basic knowledge

6 · cnc design website

7 · best cnc projects for beginners

Ammo boxes are typically made of metal, plastic, or a combination of both. Metal ammo boxes are commonly used for military and outdoor applications due to their durability and weather-resistant properties, while plastic ammo boxes are lighter and more affordable.

In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your .

It’s an art form, requiring a keen eye for design and a deep understanding of the process. In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different .Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface . CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, . Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best .

Making a design for CNC machining requires expertise. Here is everything you need to know about CNC machining design and guidelines. Product teams that focus on DFM throughout the design phase can drastically reduce production times and costs associated with CNC machined parts. In this downloadable guide, we’ve compiled eight common DFM .

In this video, you’ll learn how to design parts for CNC machining. After watching this video you'll have in-depth knowledge of the most important design aspe.In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining.

It’s an art form, requiring a keen eye for design and a deep understanding of the process. In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different CNC operations, we’re diving into how to sculpt your designs for peak CNC performance.

Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations. CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, cutter type, and depth of cut, are taken care of at the machine shop, but there are some things you can do while designing your product to not only make sure it can be made . Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best practices for different CNC operations. Read on to .

Making a design for CNC machining requires expertise. Here is everything you need to know about CNC machining design and guidelines. Product teams that focus on DFM throughout the design phase can drastically reduce production times and costs associated with CNC machined parts. In this downloadable guide, we’ve compiled eight common DFM considerations that should remain top-of-mind when designing parts for CNC machining.In this video, you’ll learn how to design parts for CNC machining. After watching this video you'll have in-depth knowledge of the most important design aspe.CNC machines may be used for milling, turning or drilling. They can create complex 2D and 3D forms from a variety of materials, from custom car parts to heavy-duty tooling applications, or even designing your own toys, games, signs and even custom furniture!

What exactly is computer-numerical-controlled (CNC) machining? It’s a means to make parts by removing material via high-speed, precision robotic machines that use an array of cutting.In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining. It’s an art form, requiring a keen eye for design and a deep understanding of the process. In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different CNC operations, we’re diving into how to sculpt your designs for peak CNC performance.Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations.

CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, cutter type, and depth of cut, are taken care of at the machine shop, but there are some things you can do while designing your product to not only make sure it can be made . Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best practices for different CNC operations. Read on to .

Making a design for CNC machining requires expertise. Here is everything you need to know about CNC machining design and guidelines. Product teams that focus on DFM throughout the design phase can drastically reduce production times and costs associated with CNC machined parts. In this downloadable guide, we’ve compiled eight common DFM considerations that should remain top-of-mind when designing parts for CNC machining.In this video, you’ll learn how to design parts for CNC machining. After watching this video you'll have in-depth knowledge of the most important design aspe.CNC machines may be used for milling, turning or drilling. They can create complex 2D and 3D forms from a variety of materials, from custom car parts to heavy-duty tooling applications, or even designing your own toys, games, signs and even custom furniture!

small cnc machine wood projects

through box electrical

The most common screw size for metal electrical boxes is #6-32, which is suitable for standard outlets and switches. However, for heavier applications like ceiling lighting and fans, an #8-32 screw provides a better hold. Ground screws in electrical boxes typically require a larger size, #10-32, and must be visibly painted green.

design cnc machine|small cnc machine wood projects