aviation cnc machine The world of aerospace CNC machining revolves around Computer Numerical Control (CNC), a technology that turns digital blueprints into physical parts with incredible accuracy. This process relies heavily on computer-aided design . Metal roofs offer numerous advantages over traditional roofing materials like asphalt shingles. Understanding the pros and cons of metal roofs can help you make an informed decision about whether a metal roof is right for your home. Read .

0 · what is aerospace cnc machining

1 · cnc aircraft type

2 · cnc aerospace parts

3 · aircraft cnc machining

4 · aerospace manufacturing cnc machining

5 · aerospace connector manufacturing machine

6 · aerospace cnc machining services

7 · aerospace cnc machine shop

In this extensive guide, we have covered the fundamentals of CNC turning inserts, explored the different types, materials, and coatings available, and provided valuable tips for selecting and using the right insert for optimal efficiency.

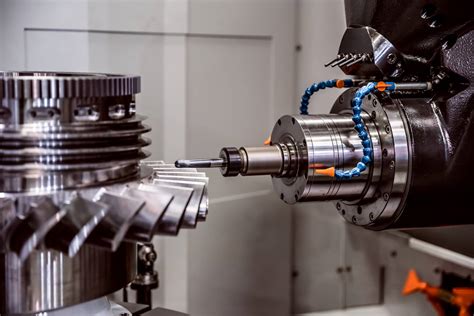

Aerospace CNC machining is the process of using computer-controlled machines to produce precise parts for the aviation and space industries. It’s designed to handle complex designs, .The world of aerospace CNC machining revolves around Computer Numerical Control (CNC), a technology that turns digital blueprints into physical parts with incredible accuracy. This process relies heavily on computer-aided design . What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, .

What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and spacecraft.Aerospace CNC machining is the process of using computer-controlled machines to produce precise parts for the aviation and space industries. It’s designed to handle complex designs, meet tight tolerances, and work with materials like titanium and aluminum.. This method ensures components are lightweight, durable, and reliable, making it essential for critical applications .The world of aerospace CNC machining revolves around Computer Numerical Control (CNC), a technology that turns digital blueprints into physical parts with incredible accuracy. This process relies heavily on computer-aided design (CAD) and computer-aided manufacturing (CAM) tools.

What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry.Aerospace CNC machining plays a pivotal role in the aviation industry by enabling the precise crafting of aerodynamic airfoils. These critical components are responsible for generating lift and managing drag during flight, making their accuracy crucial for optimal aircraft performance.

CNC Machining aerospace parts creates lightweight, durable materials and supports rapid prototyping, low-volume, and high-volume production, meeting strict safety standards while reducing lead times and minimizing human error. The aerospace CNC machining process involves using computer-controlled machine tools to shape raw materials, such as metals or composites, into finished aerospace components. The process starts with a digital 3D model .Ardel Engineering & Manufacturing works with some of the world's leading aircraft and aerospace companies. Aerospace manufacturers use CNC machining to assemble and maintain essential aircraft and space shuttle components.

what is aerospace cnc machining

Aerospace CNC machining refers to the process of using computer numerical control (CNC) machines to manufacture precision components for the aerospace industry. This involves the use of advanced machinery and software to produce complex parts with tight tolerances required for aircraft and spacecraft.CNC machining delivers unrivaled precision and accuracy, ensuring that aerospace parts meet exact specifications. This is especially important for critical aerospace systems, such as turbine engines, landing gear and structural elements, where even a slight deviation can significantly impact performance, safety and durability. What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and spacecraft.Aerospace CNC machining is the process of using computer-controlled machines to produce precise parts for the aviation and space industries. It’s designed to handle complex designs, meet tight tolerances, and work with materials like titanium and aluminum.. This method ensures components are lightweight, durable, and reliable, making it essential for critical applications .

The world of aerospace CNC machining revolves around Computer Numerical Control (CNC), a technology that turns digital blueprints into physical parts with incredible accuracy. This process relies heavily on computer-aided design (CAD) and computer-aided manufacturing (CAM) tools. What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry.

Aerospace CNC machining plays a pivotal role in the aviation industry by enabling the precise crafting of aerodynamic airfoils. These critical components are responsible for generating lift and managing drag during flight, making their accuracy crucial for optimal aircraft performance.

CNC Machining aerospace parts creates lightweight, durable materials and supports rapid prototyping, low-volume, and high-volume production, meeting strict safety standards while reducing lead times and minimizing human error. The aerospace CNC machining process involves using computer-controlled machine tools to shape raw materials, such as metals or composites, into finished aerospace components. The process starts with a digital 3D model .Ardel Engineering & Manufacturing works with some of the world's leading aircraft and aerospace companies. Aerospace manufacturers use CNC machining to assemble and maintain essential aircraft and space shuttle components.

Aerospace CNC machining refers to the process of using computer numerical control (CNC) machines to manufacture precision components for the aerospace industry. This involves the use of advanced machinery and software to produce complex parts with tight tolerances required for aircraft and spacecraft.

cnc aircraft type

metal is used to fabricate aircraft

metal junction box cover

One important type of stainless steel contains 18% chromium and 8% nickel. It is widely used in building stream lined trains, food handling equipments, kitchenwares and in many other applications which require great strength and resistant to corrosion.

aviation cnc machine|cnc aerospace parts