cnc machine 101 CNC, or Computer Numerical Control, machining refers to the process of using computers to control machine tools. This technology allows for greater precision, complexity, and efficiency . Discover three stylish ways to hang multiple pendant lights in your space, from junction boxes to track lighting and multi-pendant canopies. Elevate your interior design with impactful lighting solutions.

0 · cnc what you need toknow

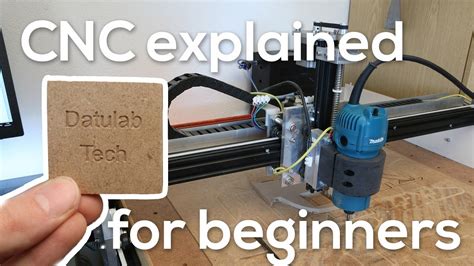

1 · cnc tutorials for beginners

2 · cnc machine for dummies

3 · cnc machine a beginner's guide

4 · cnc for beginners video

5 · basics of the cnc mill

6 · basic knowledge of cnc machine

7 · basic cnc for beginners

Sandblasting takes a lot of air and it's based on the nozzle size. Whatever size nozzle you're using will erode out to the next size up, so use that as your number. A 5/16 nozzle at 100psi will use about 140cfm. I'd look at that .

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed .

In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and . Here we’ll talk about the CNC basics for beginners covering FAQs like what machine you need to buy, what bits should you get, the definition .CNC machines perform incredible tasks that efficiently produce intricate components, surpassing traditional machining methods in both precision and cost-effectiveness. In this article, we’ll take a high-level look at CNC machine .CNC, or Computer Numerical Control, machining refers to the process of using computers to control machine tools. This technology allows for greater precision, complexity, and efficiency .

Computer numerical control machining, most often referred to simply as CNC machining, is the result of a long evolutionary process in manufacturing technology. Replacing most human interaction with automated, . CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material.

cnc what you need toknow

To get started in CNC, you must understand the CNC Basics. This guide will help you find top CNC tutorials suitable for beginners. We’ll guide you on the critical concepts you need to learn and the sequence to follow.CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding. In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and setting up the machine.

Here we’ll talk about the CNC basics for beginners covering FAQs like what machine you need to buy, what bits should you get, the definition and working of CNC system, and more.CNC machines perform incredible tasks that efficiently produce intricate components, surpassing traditional machining methods in both precision and cost-effectiveness. In this article, we’ll take a high-level look at CNC machine parts and functions.CNC, or Computer Numerical Control, machining refers to the process of using computers to control machine tools. This technology allows for greater precision, complexity, and efficiency in manufacturing compared to traditional methods. Computer numerical control machining, most often referred to simply as CNC machining, is the result of a long evolutionary process in manufacturing technology. Replacing most human interaction with automated, software-driven equipment, CNC techniques facilitate the operation of complex tools and machinery on the factory floor.

What Are CNC Machines? CNC machining is a manufacturing process that uses computerized controls and machine tools to remove stock material from the workpiece and produce custom shapes and designs.

CNC machining is a process in which computer-controlled tools remove material from a workpiece to create the desired shape or finish. CNC machining is often used for creating prototypes or small batches of parts, as it is more precise and faster than traditional methods such as manual machining or casting. CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material. To get started in CNC, you must understand the CNC Basics. This guide will help you find top CNC tutorials suitable for beginners. We’ll guide you on the critical concepts you need to learn and the sequence to follow.CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding.

In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and setting up the machine. Here we’ll talk about the CNC basics for beginners covering FAQs like what machine you need to buy, what bits should you get, the definition and working of CNC system, and more.

CNC machines perform incredible tasks that efficiently produce intricate components, surpassing traditional machining methods in both precision and cost-effectiveness. In this article, we’ll take a high-level look at CNC machine parts and functions.CNC, or Computer Numerical Control, machining refers to the process of using computers to control machine tools. This technology allows for greater precision, complexity, and efficiency in manufacturing compared to traditional methods. Computer numerical control machining, most often referred to simply as CNC machining, is the result of a long evolutionary process in manufacturing technology. Replacing most human interaction with automated, software-driven equipment, CNC techniques facilitate the operation of complex tools and machinery on the factory floor.What Are CNC Machines? CNC machining is a manufacturing process that uses computerized controls and machine tools to remove stock material from the workpiece and produce custom shapes and designs.

cnc tutorials for beginners

Metal boxes need a proper depth plaster ring and make it harder when a DIY cuts the drywall due to the rounded edges. Plastic boxes and NM are about twice as fast to install over metal. Plastic have the built-in nail vs needing screws to secure a metal box or stapling the box to a .

cnc machine 101|cnc tutorials for beginners