waviness in sheet metal drawing process Low volume batches Hydro-forming – cheap tooling, no net thinning, slow(ish), high formability Low volume batches See more $29.99

0 · sheet metal wrinkling

1 · sheet metal shearing process pdf

2 · sheet metal operations

3 · sheet metal forming processes

4 · sheet metal die forming

5 · sheet metal cutting operations pdf

6 · sheet metal characteristics pdf

7 · sheet metal bending process pdf

Walter Mork Sheetmetal. PHONE: (510) 845-0992 FAX: (510) 845-2358. 2418 – 6th Street, Berkeley, CA, 94710 Hours: 7:30-4:00 M-F. MAP & DIRECTIONS. General inquiries: .

By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and . See more

Low volume batches Hydro-forming – cheap tooling, no net thinning, slow(ish), high formability Low volume batches See more* source: http://www.cyrilbath.com/sheet_process.html See more

At Y, material defoms (‘flows’) in compression and fails in tension Interested in elastic and plastic effects: See moren eff assuming perfectly plastic, yielding at: σ = Y eff See more

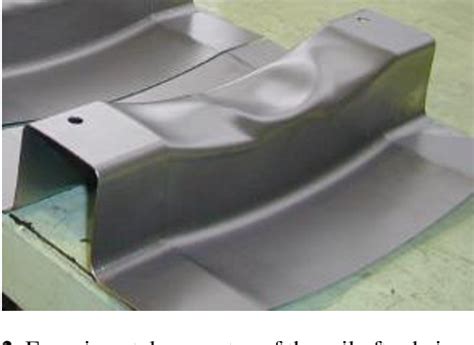

Basic types of sheet metal forming using press tools are given as follows: Drawing and deep drawing: In the following paragraphs, disruption with figures is provided for each of the above .waviness that is developed on the flange. If the flange is drawn into the die hole, it will be retained in cup wall region. Tearing: It is a crack in the cup, near the base, happening due to high . The incremental sheet metal forming process, one of these novel techniques, has attracted a great deal of attention in recent decades. This paper presents a review of recent .Surface texture refers to the characteristics of a material’s outermost layer that can be observed and felt when touched or examined closely. It encompasses several key aspects, including .

For more efficient engineering application, a theoretical model for waviness height is proposed based on the generation mechanism, using a modified strain function considering .

This article presents the process of design, analysis, manufacture and testing of a vibrating forming tool for the development of ultrasonic vibration–assisted incremental sheet .Surface waviness is one of the main types of failures in the sheet metal forming process which is a manufacturing process employed in many industries. The proposed research should lead to .less undescribed waviness of the sheet becomes more important. Our study presents the evolution of various topography parameters from skin pass rolling over electrogalvanizing and .

The metal silos and roof structures can be built by using cylindrical shells in the form of thin-walled isotropic plane rolled sheets that can be welded, riveted, or screwed around the silo or roof .

Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight The deep drawing process in sheet metal fabrication is highly dependent on the precision and quality of die design. As one of the primary determinants of the final product’s quality and dimensional accuracy, the die . 8. SHEARING • It is a process of cutting a straight line across a strip, sheet • Metal is placed between upper punch & lower die. • Pressure is applied, plastic deformation takes place. • As the pressure is continued, the . Although there exist studies relating the dynamics in the rolling process and the final product surface characteristics , the surface finishing and waviness of sheet metal plates are still unpredictable in many machining processes [2,3], and the tools used in its characterization are becoming more and more sophisticated . In this article we .

Improvement strategy for edge waviness in roll bending process of corrugated sheet metals Do-Sik Shim1 & Jong-Youn Son2 & Eun-Mi Lee2 & Gyeong-Yun Baek2 Received: 27 January 2016/Accepted: 9 June 2016/Published online: 16 June 2016 Abstract This paper focuses on the corrugated thin-walled sheet metal in the roll bending process. The main“Earing” is a waviness in the top edge of a cup drawn from sheet metal. When a cup is drawn the top edge is noticed to naturally form an oscillating pattern. This results from anisotropy of the rolled sheet caused by the rolling process. Each peak is known as an “Ear” and “Earing” is the ring of ears around the top of the cup. 4. Wrinkling Wrinkles appear both on the flange and on the wall during cup drawing and deep drawing operation. This is like ups and downs or waviness. The tendency for wrinkling increases with decreasing thickness, nonuniform thickness, increasing length or surface area of sheet that is not constrained or supported. Remedies- Wrinkles can be eliminated by .

1980s metal happydays lunch box for sale

Metal Drawing process involves transformation of metals into various parts and components by using different processes. It is of different types based on requirement . Deep drawing metal is a metal forming process where a flat sheet of metal is drawn into a die cavity to create a three-dimensional, cup-like shape with significant depth.volume and mass of the metal are conserved. Deep drawing is a well-established sheet metal forming process where a deformable blank is hold between rigid die and binder, and punch is given motion to deform the blank into a hollow cup as shown in Fig.1.The sheet metal undergoes different stress state, mainlyThe deep drawing of sheet metals can possibly initiate cracks (tearing) in the blank (e.g. at low corner radii) or result in wrinkling (e.g. because of low blank holder force) . . Punching is usually the cheaper process. If the sheet metal is already heat treated during the manufacturing process by a laser or the flat sheet metal blank is . Deep drawing is one of widely used sheet metal working process in industries to produce cup shaped components at a very high rate. In deep drawing process, a sheet metal blank form cylindrical .

Metal gainers in the draw die or in the die prior to the stretch flange operation compensates for change in length of line that occurs during flanging, helping to avoid edge cracking. In the example shown in Figure 4, edge fractures moved from the draw panel to flanged panel after grinding on the draw die to eliminate edge fractures in the draw . Analysis and Optimization of Sheet Metal Forming Processes comprehensively covers sheet metal forming, from choosing materials, tools and the forming method to optimising the entire process through finite element analysis and computer-aided engineering.. Beginning with an introduction to sheet metal forming, the book provides a guide to the various .the substrate waviness by the galvanizing process may occur in different ways. Fig. 3: Production chain for galvanized steel sheet. 2 Roughness and waviness Currently the surface texture is commonly described by various 2d roughness parameters, such as the arithmetic average of roughness R a and peak count RP c [1].

The deep drawing process, thanks to its high productivity, is a sheet metal forming process commonly adopted in the automotive, aeronautical, and food industries [1][2][3][4].The Importance of Working Drawings as Legal Documents; Types of Engineering Drawings. Tabulated Drawing; . (Sheet Metal Process) Turret Punch Press; Bending (Sheet Metal Process) Sheet Metal Brakes . . be observed and felt .The plane indicated by the instructional arrow in the figure must be parallel to datum plane A (a plane which is defined as flat even if there is warpage/waviness on the actual target) and must fall between two projected planes separated by .

In the one-step manufacturing process for fiber metal laminate parts, the so-called in situ hybridization process, the fabrics are interacting with metal blanks. During deep drawing, the liquid matrix is injected between the metal sheets through the woven fiber layers. A Sheet Metal Forming (SMF) process, especially deep drawing, is one of the manufacturing processes that commonly used in the automotive industry. In order to study the influence factors of steel sheet surface waviness in cold rolling process, using coherence scanning interferometry, the surface waviness with different cold rolling processes .Bending is a process in sheet metal fabrication that imparts shape and structure to flat sheets, transforming them into three-dimensional components. This technique generally involves the use of a press brake, where the sheet metal is positioned between a punch and a die.

As a major sheet metal process for fabricating cup or box shapes, the deep drawing process is commonly applied in various industrial fields, such as those involving the manufacture of household .Searching on various random sheet metal drawings I've seen, it's weird because it looks like everything is dimensions to 3 decimal places regardless of how critical the feature might be. . the purpose of a detailed drawing is to define a completed part --- not to define the process by which to arrive at the completed part. Deep Drawing Process for Sheet Metal. satyendra; August 28, 2023; 7 Comments ; Anisotropy, Blank, Blank holder, Deep drawing, die, drawability, Earing, Expanding, Ironing, Limiting draw ratio, lubrication, Necking, Plastic strain ratio, Punch, Strain hardening exponent, Tearing, Trimming, Wrinkling,; Deep Drawing Process for Sheet Metal. Deep drawing is a .

In the conventional deep drawing (CDD) process, the sheet metal is formed into a cup-shaped component. In this process, a flat circular . (2002) defined earing as the formation of waviness on the top of the drawn cup. The number of ears formed is commonly four (Hosford and Caddell, 2007), but might also be two, six, or eight, depending on the .The objective of this research proposal is to gain an insight into the relatively unexplored area of surface waviness (or wrinkling) which can occur during sheet metal forming, to obtain a fundamental understanding of the influence of material parameters on those process parameters that cause surface waviness, and to provide technical guidelines for avoiding such defects in .After drawing, the circles are observed for failure. . waviness that is developed on the flange. If the flange is drawn . Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape change.

sheet metal wrinkling

$10.48

waviness in sheet metal drawing process|sheet metal die forming