aerospace cnc machining manufacturing In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface . Get the best deals for vintage star wars lunch box metal at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

0 · what is aerospace cnc machining

1 · machining aerospace parts

2 · cnc machining aerospace parts

3 · cnc aerospace parts

4 · aircraft cnc machining

5 · aerospace connector manufacturing machine

6 · aerospace cnc machining services

7 · aerospace cnc machine shop

$450.00

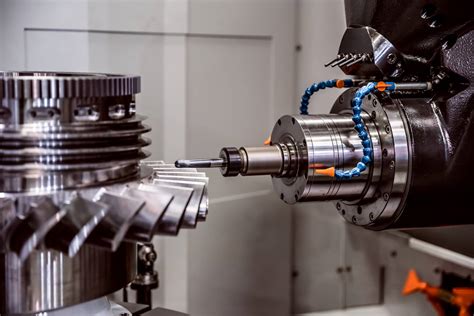

Aerospace CNC machining stands at the forefront of modern manufacturing, driving innovation in the aerospace industry through precision and efficiency. This guide delves into the intricacies of CNC machining tailored for .

The world of aerospace CNC machining revolves around Computer Numerical Control (CNC), a technology that turns digital blueprints into physical parts with incredible accuracy. This process relies heavily on computer-aided design . In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface . This article explains what aerospace CNC machining is and the typical materials used in aerospace manufacturing. You’ll also learn about precision and tight tolerances in aerospace machining, multi-axis CNC .

Aerospace CNC machining stands at the forefront of modern manufacturing, driving innovation in the aerospace industry through precision and efficiency. This guide delves into the intricacies of CNC machining tailored for aerospace applications, exploring the advanced techniques, specialized materials, and stringent quality standards that ensure .

The world of aerospace CNC machining revolves around Computer Numerical Control (CNC), a technology that turns digital blueprints into physical parts with incredible accuracy. This process relies heavily on computer-aided design (CAD) and computer-aided manufacturing (CAM) tools. In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface treatments, and applications that make this technology so essential to the industry. This article explains what aerospace CNC machining is and the typical materials used in aerospace manufacturing. You’ll also learn about precision and tight tolerances in aerospace machining, multi-axis CNC machines for aerospace parts, .

Aerospace CNC manufacturing can be integrated with additive manufacturing (AM) for post-processing operations. There are also hybrid machines that can switch between adding material with 3D printing and subtracting material with CNC machining.The integration of CNC machining with additive manufacturing processes, such as 3D printing, will unlock new possibilities in aerospace manufacturing. CNC machining can be employed for post-processing, surface finishing and adding final details to 3D-printed parts.

The aerospace CNC machining process involves using computer-controlled machine tools to shape raw materials, such as metals or composites, into finished aerospace components. The process starts with a digital 3D model .

Aerospace CNC machining is the process of using Computer Numerical Control (CNC) technology to manufacture parts for the aerospace industry. This technology ensures precise and efficient production, resulting in high-quality components for various applications.In the aerospace industry, CNC machining plays a crucial role in producing high-precision components for aircraft and spacecraft. CNC (Computer Numerical Control) technology is used to automate the manufacturing of complex parts, ensuring accuracy and consistency in every piece. What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry. Aerospace CNC machining stands at the forefront of modern manufacturing, driving innovation in the aerospace industry through precision and efficiency. This guide delves into the intricacies of CNC machining tailored for aerospace applications, exploring the advanced techniques, specialized materials, and stringent quality standards that ensure .

The world of aerospace CNC machining revolves around Computer Numerical Control (CNC), a technology that turns digital blueprints into physical parts with incredible accuracy. This process relies heavily on computer-aided design (CAD) and computer-aided manufacturing (CAM) tools.

what is aerospace cnc machining

In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface treatments, and applications that make this technology so essential to the industry.

This article explains what aerospace CNC machining is and the typical materials used in aerospace manufacturing. You’ll also learn about precision and tight tolerances in aerospace machining, multi-axis CNC machines for aerospace parts, .Aerospace CNC manufacturing can be integrated with additive manufacturing (AM) for post-processing operations. There are also hybrid machines that can switch between adding material with 3D printing and subtracting material with CNC machining.The integration of CNC machining with additive manufacturing processes, such as 3D printing, will unlock new possibilities in aerospace manufacturing. CNC machining can be employed for post-processing, surface finishing and adding final details to 3D-printed parts.

The aerospace CNC machining process involves using computer-controlled machine tools to shape raw materials, such as metals or composites, into finished aerospace components. The process starts with a digital 3D model .

Aerospace CNC machining is the process of using Computer Numerical Control (CNC) technology to manufacture parts for the aerospace industry. This technology ensures precise and efficient production, resulting in high-quality components for various applications.In the aerospace industry, CNC machining plays a crucial role in producing high-precision components for aircraft and spacecraft. CNC (Computer Numerical Control) technology is used to automate the manufacturing of complex parts, ensuring accuracy and consistency in every piece.

machining aerospace parts

Below, we highlight metal roof and siding color combinations to consider in 2021. Gray is a versatile metal roof color. For one, it comes in a variety of shades. That enables it to fit many styles, from edgy to modern and everything in .

aerospace cnc machining manufacturing|aerospace cnc machining services