how does a cnc machine operate In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF. $2.00

0 · introduction to cnc machining

1 · how to operate cnc machine

2 · how to cnc machining work

3 · how cnc machine is controlled

4 · explain working of cnc machine

5 · cnc machining explained

6 · basic of cnc machine

7 · basic knowledge of cnc machine

Highlight areas surrounding your home by using the Landscape Lighting Tree Mount Junction Box by WAC Lighting. This kit includes tree-safe stainless steel mounting screws and two 0.5'' NPT threaded holes for simple installation.

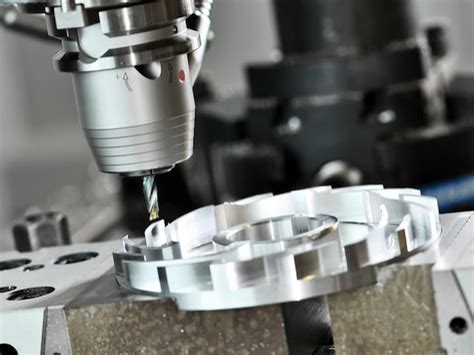

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at Cutting . In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

November 15, 2024. In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials. Unlike manual milling, where an operator’s steady . CNC machines function by interpreting G-code to precisely cut materials into desired shapes with minimal human intervention. Different types of CNC machines, such as milling and turning machines, cater to specific .

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines: . What you'll learn from this video. 0:47 First, you’ll learn what CNC machining is and how CNC machines operate. 1:03 Second, we’ll show you the basic process of CNC .Learn about CNC machining processes in the comprehensive guide by Dassault Systèmes, enabling precise and efficient production of complex parts.In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle .

At its core, a CNC machine is a computer-controlled device that automates the operation of machine tools, such as mills, lathes, routers, and grinders. Unlike conventional manual machines, where operators physically manipulate tools, .

Latest Post. What Software Do CNC Machines Use: A Comprehensive Guide December 9, 2023 - 5:28 am; What Language Do CNC Machines Use? A Comprehensive Guide December 9, 2023 - 2:29 am; What .

Those who want to work with heavy machinery may want to know the answer to, "What does a CNC machine operator do?" CNC machine operators, or machining tool operators, produce machined parts using computer programming skills. They also keep detailed records of their progress and daily responsibilities. These professionals often use calibration .The exact movements that this code controls depends on the type of CNC machine that is being used. Let’s take a look at some of the most common CNC machines in use today, and how they work: Types of CNC Machines #1 CNC milling machines. CNC milling is one of the most common types of CNC machining, known for its great accuracy and tolerances .What is a CNC Router? CNC routers are one popular application for CNC machining platforms. As an advanced type of tooling method, CNC routers operate with CAM software programs, a visual programming tool used to create geometric code or simply, g-code, the CNC computer language that operates the CNC machines. CNC machines consist of several key components, including the control unit (which interprets the NC program and sends commands to the machine), motors and actuators (which move the machine’s axes), spindle (which holds the cutting tool), tool changers (for automatic tool changes), and workholding devices (such as vises or clamps to secure the .

What does a CNC Operator do in the Manufacturing Industry? A CNC (Computer Numerical Control) Operator is responsible for running CNC machines that cut, shape, and finish metal and other materials. They input instructions into the machine, ensure materials are properly loaded, supervise the cutting process, make adjustments as necessary, and . CNC Machine Components. Understanding the key components of a CNC machine is crucial to grasping how they work. Here are the main parts: Computer and Controller: The brain of the operation, responsible for interpreting the programming and controlling the machine’s movements. Machine Tool: The actual cutting or shaping tool, such as a drill, lathe, .How long does a CNC punching machine last? A CNC punching machine’s lifespan can range from 10 to 15 years, depending on the usage, maintenance, and working environment. Its lifespan can be extended significantly with regular maintenance and proper use. What is the impact of CNC punching on production costs? Conversion: For all our non-U.S. friends, 1 Thou is equal to .0254 mm. TITANS of CNC: Academy: http://bit.ly/2J6mvhOAutodesk Free Trials: Inventor - https://.

Before showing you how does a CNC lathe works, you should know what this type of industrial machine is. CNC lathes are fully automated machines controlled by computer numerical control software.One of the main advantages is that they can perform different tasks and easily position the X, Y or Z axes.How Does a CNC Machine Work? Operating a CNC machine involves setting up the machine, preparing the material, and inputting a design file. The machine’s software then interprets the file, guiding the cutting tool to replicate the design. How Do CNC Machines Work? CNC machines usually feature a version of a CAD software program. A CAD program, or computer-aided design, is software which allows you to draw what you want to cut. The drawing is either 2D or 3D and when completed it a creates a code for the CNC machine to read. CNC machines work by following co-ordinates along axis.

Being more competitive means buying a more capable cnc machine. Factors Affecting CNC Machine Cost. These are the broad factors that determine CNC Machine Cost. CNC Machine Size. The size of the machine, typically measured as the cnc machine’s work envelope (X, Y, and Z coordinate range), is a huge determiner of machine cost.Most residential service meters do not measure the Var so capacitive power loads do not get metered. The servos or steppers do not use much power. That is why you should not see much difference in your power bill. That is also why you need a larger breaker to handle the power up surge from the capacitive load when the machine is first turned on. How Does a CNC Lathe Machine Work? A CNC lathe machine works by using computerized controls to move a cutting tool along a spinning material. The computer controls the movement, speed, and position of the .

So, how does CNC milling machines work? We tell you about it below, keep reading! STEP 1: Preparation. First of all, make sure the machine is equipped with the correct tools to perform the job and the raw material is secured in place . Watch Next - 3D Printer Basics: https://youtu.be/RgECxaxUIb0CNC Routers for Hobbyists can be intimidating! In this video, I'll cover all the CNC basics that .

introduction to cnc machining

how to operate cnc machine

How Does a CNC Machine Work? A CNC machine works by following a computer-aided design (CAD) file, which is a digital model of the part or object that needs to be created. This CAD file is then converted into a set of numerical data, called G-code, that tells the CNC machine how to move. The machine can cut, shape, drill, or engrave materials .

How Does a Wood CNC Router Machine Work? The Acronym CNC stands for “Computer Numerical Control”. Dictionary.com defines it as an automated operation of a machine by a computer program. A standard CNC router machine (as well as other popular CNC equipment such as plasma, water jet, 3D printers, or CNC laser cutters) is controlled by a .Question: HOW DO CNC MACHINES WORK? Current Solution. A CNC machine takes codes from a computer and converts the code using software into electrical signals. The signals from the computer are then used to control motors. Since the motors can turn very small amounts the machine is able to move in highly precise movements over and over again.

how to cnc machining work

CNC mills are often classified by the number of axes on which they can operate or spindle directions. 1. Vertical Mill. A vertical mill or milling machine’s spindle axis is vertically oriented, which means the cutting tools on the spindle will shape the materials vertically, and the cutters move while the workpiece remains stationary, the machines can cut into the part easily.

how cnc machine is controlled

How Do CNC Machines Work? Modern CNC machines are entirely automatic. All they require are digital files that provide information on the tools and cutting trajectories. To create a certain product, design or machining operations need to use several tools. Machinists are able to create digital tool libraries that connect to the actual machine. #cncmachining In this video, you’re going to learn what CNC machining is and how it works. After watching you will have a good understanding of CNC machining. This means that the machine is automated, allowing it to use set instructions from a computer system to fashion materials. The advantage of not needing a manual operator allows CNC routers to gain wide use in many woodworking . First-time CNC machine setup and operation can be intimidating. Here's your guide to setting up a CNC lathe, as well as insider tips for achieving a quality result. . Though it does take a lot of skill and training to operate a CNC lathe, the results have a positive impact on the final product and the company’s bottom line over using .

Types of CNC Machines. There are several types of CNC machines, each with varying levels of complexity and capabilities. The most common types include 3-axis, 4-axis, and 5-axis machines. 3-axis CNC machines are the simplest type and operate on .

explain working of cnc machine

Machine operators set-up, operate, and maintain machinery, usually in a manufacturing setting. They are responsible for ensuring the machine produces high quality products, runs smoothly and at capacity, and is properly maintained.

Tri-Metal Fabricators in Surrey is known for producing quality steel and sheet metal products for a variety of industrial sectors, and it does so in a 36,000 square foot plant equipped with laser and plasma cutters, massive rollers and specialized equipment.

how does a cnc machine operate|introduction to cnc machining