cnc additive manufacturing large scale LSAM - Large Scale Additive Manufacturing. Large industrial “Near Net Shape”, composite additive manufacturing machines that can print and trim on the same machine. What is a Junction Box? Vorlane defines junction boxes as enclosures for protecting and safeguarding electrical connections. They are also suitable for organizing big loops of wires in a place. A junction box also combines different cables when needed.

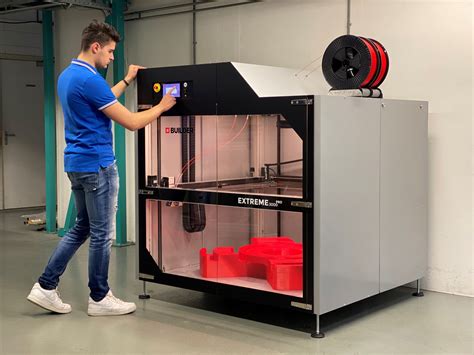

0 · large size 3d printing

1 · large 3d printing services possibilities

2 · large 3d printers for manufacturing

3 · 3d printing with cellulose materials

4 · 3d printing service big scale

5 · 3d printing large scale manufacturing

6 · 3d printing large objects

7 · 3d printing for large scale

A flange in custom sheet metal fabrication is a feature consisting of a bent face that connects to an existing face, adding strength and a finished .

We offer innovative & high-performance additive manufacturing solutions to enable a smarter serial production of large polymer & composites parts - that means, up to thousands of large .LSAM - Large Scale Additive Manufacturing. Large industrial “Near Net Shape”, composite additive manufacturing machines that can print and trim on the same machine.

We are delighted to show an industrial solution from CEAD for multi-axis composite printing combining Comau’s robotics, CEAD’s Additive Manufacturing and our best in class CNC .The BEAD forms an all in one solution for both large scale 3D printing as well as precision milling. These features enable the BEAD to 3D print the near net shape of a part and after completion milling it to the required tolerances with a CNC . LEAM Technologies is revolutionizing large format additive manufacturing (LFAM) with light-based welding technology. . printing (Directed Energy Deposition, Cold Spray), welding, control and milling tasks. VLM .High-performance, affordable American-Made Thermwood CNC Routers are used in Wood, Plastics, Aerospace, Composites, Foam, Non-Ferrous Metals & now additive with the LSAM .

large size 3d printing

Large scale additive manufacturing (LSAM) transforms the way of producing large pieces. Granulate-based printing is 37 times faster than filament-based methods on average, enabling .We offer innovative & high-performance additive manufacturing solutions to enable a smarter serial production of large polymer & composites parts - that means, up to thousands of large scale end-use parts per year.LSAM - Large Scale Additive Manufacturing. Large industrial “Near Net Shape”, composite additive manufacturing machines that can print and trim on the same machine.

We are delighted to show an industrial solution from CEAD for multi-axis composite printing combining Comau’s robotics, CEAD’s Additive Manufacturing and our best in class CNC technology.The BEAD forms an all in one solution for both large scale 3D printing as well as precision milling. These features enable the BEAD to 3D print the near net shape of a part and after completion milling it to the required tolerances with a CNC milling machine. LEAM Technologies is revolutionizing large format additive manufacturing (LFAM) with light-based welding technology. . printing (Directed Energy Deposition, Cold Spray), welding, control and milling tasks. VLM Robotics’ range of CNC robotic machines can be seamlessly integrated into the production environment, enabling agile repair and .High-performance, affordable American-Made Thermwood CNC Routers are used in Wood, Plastics, Aerospace, Composites, Foam, Non-Ferrous Metals & now additive with the LSAM Large Scale Additive Manufacturing System.

Large scale additive manufacturing (LSAM) transforms the way of producing large pieces. Granulate-based printing is 37 times faster than filament-based methods on average, enabling large constructions to be printed efficiently. UPM Formi .This page answers the most important questions concerning large scale additive manufacturing, such as ‘what is LSAM’, ‘what are the different types of LSAM’ and ‘what are the benefits of LSAM’. Furthermore, CEAD’s large scale additive manufacturing solutions are highlighted. Last year, Thermwood began exploring the additive manufacturing realm with their double gantry 3D printer/CNC machine combo idea. Now the company has announced that they are introducing a brand.

We offer cost effective and outstanding wire arc additive manufacturing (WAAM) solutions, from concept to end use, for large scale industrial metal components.We offer innovative & high-performance additive manufacturing solutions to enable a smarter serial production of large polymer & composites parts - that means, up to thousands of large scale end-use parts per year.

LSAM - Large Scale Additive Manufacturing. Large industrial “Near Net Shape”, composite additive manufacturing machines that can print and trim on the same machine.

We are delighted to show an industrial solution from CEAD for multi-axis composite printing combining Comau’s robotics, CEAD’s Additive Manufacturing and our best in class CNC technology.The BEAD forms an all in one solution for both large scale 3D printing as well as precision milling. These features enable the BEAD to 3D print the near net shape of a part and after completion milling it to the required tolerances with a CNC milling machine. LEAM Technologies is revolutionizing large format additive manufacturing (LFAM) with light-based welding technology. . printing (Directed Energy Deposition, Cold Spray), welding, control and milling tasks. VLM Robotics’ range of CNC robotic machines can be seamlessly integrated into the production environment, enabling agile repair and .

High-performance, affordable American-Made Thermwood CNC Routers are used in Wood, Plastics, Aerospace, Composites, Foam, Non-Ferrous Metals & now additive with the LSAM Large Scale Additive Manufacturing System.Large scale additive manufacturing (LSAM) transforms the way of producing large pieces. Granulate-based printing is 37 times faster than filament-based methods on average, enabling large constructions to be printed efficiently. UPM Formi .This page answers the most important questions concerning large scale additive manufacturing, such as ‘what is LSAM’, ‘what are the different types of LSAM’ and ‘what are the benefits of LSAM’. Furthermore, CEAD’s large scale additive manufacturing solutions are highlighted. Last year, Thermwood began exploring the additive manufacturing realm with their double gantry 3D printer/CNC machine combo idea. Now the company has announced that they are introducing a brand.

large 3d printing services possibilities

large 3d printers for manufacturing

3d printing with cellulose materials

sheet metal screw pullout strength

What is the Purpose of a Power Distribution Box? A power distribution box, also known as a distribution board, is a critical component in electrical systems. It ensures the safe and efficient distribution of electrical power from the main supply to various circuits within a .The most durable lunch box materials are metal and glass. These materials are very strong ensuring your lunch box will last a very long time. Lunch boxes made from silicone and .

cnc additive manufacturing large scale|3d printing with cellulose materials