break off tabs sheet metal Sheet metal fabrication uses notches and tabs to make further machining operations easier and eliminate space conflicts during assembly. This article will go through several types of notches, dimensioning & tolerancing . Before you head off to get your materials, here are some of the different types of sheet metal and their advantages and disadvantages. Alloy steel, as the name implies, mixes various components to provide a customisable set of characteristics. Carbon steel serves as this material's primary element. Other components are included, such as:

0 · tabs for metal sheets

1 · punching sheet metal tabs

2 · how to make tabs on metal sheet

3 · how to make tabs on metal

Sheet metal joining operation is crucial part of the sheet metal fabrication process. Joint reliability depends on its type, sheet metal material, and manufacturing process. This article covers various types of sheet metal joining techniques, their advantages, disadvantages, and applications.

External tabs formed by precision machining will produce a break-off point that will leave a small part of the metal sheet on the part. If you have one of Fotofab’s business cards, you may be able to feel the external burr used on our cards. One of our favorite sheet metal tricks to get “impossible” bends in your part. You don’t always need to add these, such as when your parts have a flat edge p. Tabs are used to keep the part attached to the sheet so it can be easily broken . Sheet metal fabrication uses notches and tabs to make further machining operations easier and eliminate space conflicts during assembly. This article will go through several types of notches, dimensioning & tolerancing .

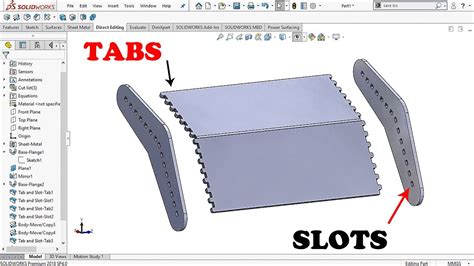

Notches, tabs, and slots are three common sheet metal design elements that can help you in more ways than you might initially think. Designing them properly is key. If your design calls for an oddly shaped flange, we’ll need you to add a flat surface using break-off tabs in order to create a parallel edge to the bend line. We have specific guidance on how to do this here: Odd Flange . For quick, clean parts separation, micro-joints (or “shake and break”) are a .Remove tabs by sanding them off by hand or using a metal file. You don’t need to add micro tabs to your design because we automatically do it for you during nesting. We make sure all tabs and lead-ins are outside your part geometry so .

Creating Sheet Metal Tabs just got a lot easier with Onshape’s most recent update. A new Sheet Metal Tab command was added that makes this a simple task. Let’s take a look. You’ll find the new Tab command with the rest of the .If your bent part requires an odd flange shape, we can bend it if you create a flat reference point or “break-off tab.” Learn how to set up your design for successful bending with an irregular flange shape.External tabs formed by precision machining will produce a break-off point that will leave a small part of the metal sheet on the part. If you have one of Fotofab’s business cards, you may be able to feel the external burr used on our cards. One of our favorite sheet metal tricks to get “impossible” bends in your part. You don’t always need to add these, such as when your parts have a flat edge p.

tabs for metal sheets

Tabs are used to keep the part attached to the sheet so it can be easily broken free once it’s removed from the machine. The most efficient tab will keep a strong enough bond to the sheet to keep the part stable, but then break cleanly without requiring a .

Sheet metal fabrication uses notches and tabs to make further machining operations easier and eliminate space conflicts during assembly. This article will go through several types of notches, dimensioning & tolerancing principles, the necessity of notches and tabs, disadvantages, and applications. Notches, tabs, and slots are three common sheet metal design elements that can help you in more ways than you might initially think. Designing them properly is key.

If your design calls for an oddly shaped flange, we’ll need you to add a flat surface using break-off tabs in order to create a parallel edge to the bend line. We have specific guidance on how to do this here: Odd Flange Considerations For quick, clean parts separation, micro-joints (or “shake and break”) are a traditional method fabricators use to separate multiple parts from a sheet of material. The traditional micro-joint method places small, interconnecting tabs between parts by programming the spacing of the slitting punch.Remove tabs by sanding them off by hand or using a metal file. You don’t need to add micro tabs to your design because we automatically do it for you during nesting. We make sure all tabs and lead-ins are outside your part geometry so your design remains true to what you originally sent us.Creating Sheet Metal Tabs just got a lot easier with Onshape’s most recent update. A new Sheet Metal Tab command was added that makes this a simple task. Let’s take a look. You’ll find the new Tab command with the rest of the sheet metal tools in the Part Studio toolbar.

punching sheet metal tabs

If your bent part requires an odd flange shape, we can bend it if you create a flat reference point or “break-off tab.” Learn how to set up your design for successful bending with an irregular flange shape.

External tabs formed by precision machining will produce a break-off point that will leave a small part of the metal sheet on the part. If you have one of Fotofab’s business cards, you may be able to feel the external burr used on our cards. One of our favorite sheet metal tricks to get “impossible” bends in your part. You don’t always need to add these, such as when your parts have a flat edge p.

ex junction box suppliers

Tabs are used to keep the part attached to the sheet so it can be easily broken free once it’s removed from the machine. The most efficient tab will keep a strong enough bond to the sheet to keep the part stable, but then break cleanly without requiring a . Sheet metal fabrication uses notches and tabs to make further machining operations easier and eliminate space conflicts during assembly. This article will go through several types of notches, dimensioning & tolerancing principles, the necessity of notches and tabs, disadvantages, and applications.

Notches, tabs, and slots are three common sheet metal design elements that can help you in more ways than you might initially think. Designing them properly is key. If your design calls for an oddly shaped flange, we’ll need you to add a flat surface using break-off tabs in order to create a parallel edge to the bend line. We have specific guidance on how to do this here: Odd Flange Considerations For quick, clean parts separation, micro-joints (or “shake and break”) are a traditional method fabricators use to separate multiple parts from a sheet of material. The traditional micro-joint method places small, interconnecting tabs between parts by programming the spacing of the slitting punch.

Remove tabs by sanding them off by hand or using a metal file. You don’t need to add micro tabs to your design because we automatically do it for you during nesting. We make sure all tabs and lead-ins are outside your part geometry so your design remains true to what you originally sent us.Creating Sheet Metal Tabs just got a lot easier with Onshape’s most recent update. A new Sheet Metal Tab command was added that makes this a simple task. Let’s take a look. You’ll find the new Tab command with the rest of the sheet metal tools in the Part Studio toolbar.

how to make tabs on metal sheet

how to make tabs on metal

Braces can correct a wide range of dental issues, including crooked, gapped, rotated or crowded teeth. There are several types of braces, including traditional metal braces, ceramic braces and clear aligners like Invisalign®. Braces improve your smile’s health, function and appearance.

break off tabs sheet metal|how to make tabs on metal sheet