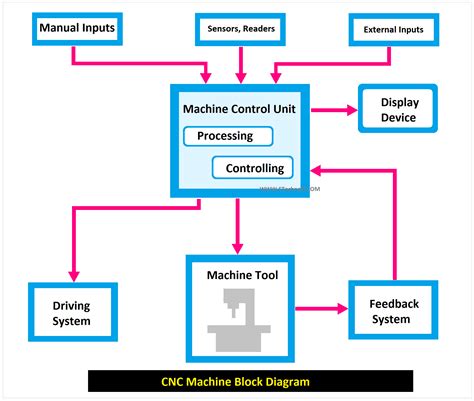

construction of cnc machine The main parts of the CNC machine are: 1. Input devices 2. Machine control unit (MCU) 3. Machine tool 4. Driving system 5. Feedback system . See more Unlike the rest of the aircraft, which is mostly made of light materials such as aluminum and plastic, the cockpit voice recorder and the flight data recorder are encased in stainless steel boxes roughly 10 inches by 10 inches by 5.

0 · working principle of cnc machine

1 · how cnc machine is controlled

2 · cnc milling machine diagram

3 · cnc mill axis diagram

4 · cnc machining process flow chart

5 · cnc machine schematic diagram

6 · cnc lathe machine diagram

7 · block diagram of cnc machine

Clearance hole chart for inch bolts and screws. Drill size and hole diameter for normal, .

In a CNC machine, all the numerical functions are controlled by the computer. The computer stores the programs which are required to operate the machine. The computer also gives the display of various parameters of the machine-like spindle speed, feed rate, etc. It consists of electronicinstrumentation to . See moreA CNC system can be described in terms of three major elements: 1. Hardware, 2. Software and 3. Information. See moreThe features of CNC machines are as follows: 1. Part program input may be through the keyboard. 2. The part program is entered into the computer and stored in the memory. Then it is used again and again. 3. The entered part program can be edited for any errors . See more

best stainless steel bento box for kids

The main parts of the CNC machine are: 1. Input devices 2. Machine control unit (MCU) 3. Machine tool 4. Driving system 5. Feedback system . See moreThe figure shows theCNC machine working: First, the part program is entered into The Mcu of the CNC. The Mcu processes all the data and according to the program . See more

To use a CNC machine, operators need to create or import a CNC program, set up the workpiece and tools, load the program into the machine's controller, and initiate the machining process while monitoring its progress and . This document discusses the constructional features of CNC machines. It classifies CNC systems according to the type of machine into point-to-point, straight-cut, and . Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages .

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, .The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how .

With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing . When building your own CNC machine, you must first figure out what type of CNC machine you want to create. This way, it will be effortless to pick the parts or pieces of equipment you need to get your machine running.By integrating a computer processor, computer numerical control, or “CNC” as it is now known, allows part machining programs to be edited and stored in the computer memory as well as .Definition of CNC Machine. Let me first introduce you about what is CNC machine, so CNC stands for Computer Numerical Control. When computers are used to control a Numerical Control (NC) machine tool than the machine is .

In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF. To use a CNC machine, operators need to create or import a CNC program, set up the workpiece and tools, load the program into the machine's controller, and initiate the machining process while monitoring its progress and making any necessary adjustments.

This document discusses the constructional features of CNC machines. It classifies CNC systems according to the type of machine into point-to-point, straight-cut, and continuous path systems. It also categorizes them based on programming method as absolute or incremental, and by control system type as open-loop or closed-loop.

Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the . What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines : There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at .

With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders. When building your own CNC machine, you must first figure out what type of CNC machine you want to create. This way, it will be effortless to pick the parts or pieces of equipment you need to get your machine running.By integrating a computer processor, computer numerical control, or “CNC” as it is now known, allows part machining programs to be edited and stored in the computer memory as well as permitting diagnostics and quality control functions during the actual machining.

Definition of CNC Machine. Let me first introduce you about what is CNC machine, so CNC stands for Computer Numerical Control. When computers are used to control a Numerical Control (NC) machine tool than the machine is called CNC machine. In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF. To use a CNC machine, operators need to create or import a CNC program, set up the workpiece and tools, load the program into the machine's controller, and initiate the machining process while monitoring its progress and making any necessary adjustments.

This document discusses the constructional features of CNC machines. It classifies CNC systems according to the type of machine into point-to-point, straight-cut, and continuous path systems. It also categorizes them based on programming method as absolute or incremental, and by control system type as open-loop or closed-loop.

Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the . What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines : There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at . With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders. When building your own CNC machine, you must first figure out what type of CNC machine you want to create. This way, it will be effortless to pick the parts or pieces of equipment you need to get your machine running.By integrating a computer processor, computer numerical control, or “CNC” as it is now known, allows part machining programs to be edited and stored in the computer memory as well as permitting diagnostics and quality control functions during the actual machining.

working principle of cnc machine

Pilot Hole Sizes for Steel Sheet Metal . ANSI Hardware Design and Application Guide ISO Metric Hardware Engineering and Design Data Fastener and Screw / Bolt Design, Formula & Calculations. Approximate Pilot Hole Sizes for Type A .

construction of cnc machine|cnc machining process flow chart