types of turret in cnc machine Learn about the three main types of CNC lathe turrets: BMT, VDI, and BOT, and their features, benefits, and differences. Compare their mounting, tool change speed, compatibility, versatility, precision, automation, and . Check out our metal u shaped brackets selection for the very best in unique or custom, handmade pieces from our shelving brackets shops.

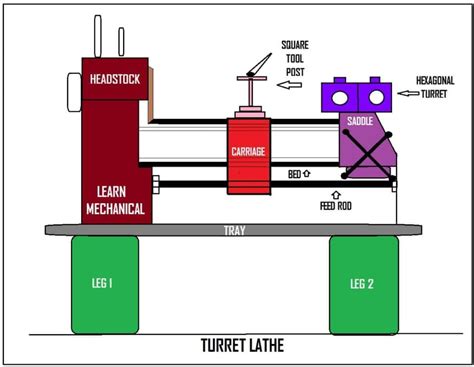

0 · turret lathe machine diagram

1 · tool turret for cnc lathe

2 · numerical control turret punch press

3 · gang tooling vs turret lathe

4 · cnc turret punching machine

5 · cnc turret punch press machine

6 · cnc lathe gang tooling

7 · capstan vs turret lathe

$23.99

Understanding the working and performance of a tool turret helps operate a CNC machine for part production more efficiently. In this article, we will study what a tool turret is, how it functions, and what can happen if it is not maintained . Tool turrets can be classified into two types: fixed and live. Fixed tool turrets are primarily used for turning operations, where the tools remain stationary, while the workpiece rotates. This type of turret is ideal for tasks like . Learn about the three main types of CNC lathe turrets: BMT, VDI, and BOT, and their features, benefits, and differences. Compare their mounting, tool change speed, compatibility, versatility, precision, automation, and .Learn about the types of lathe turrets, their historical evolution, and the advantages they bring to CNC machining and industrial manufacturing. Enhance your knowledge on how these tools boost efficiency and precision in turning .

Turrets in CNC machines come in various types, each designed to improve efficiency and precision in different machining operations. Let’s explore the main types: horizontal orientation, vertical orientation, and multi-tool holding.Here, we will explore the different types of CNC machine turret assemblies available in the market. We will discuss the characteristics, advantages, and limitations of each type, including .Learn about the different types of turret lathes, how they work, and how they differ from engine lathes and capstan lathes. A turret lathe is a metalworking machine that uses a rotating turret to hold and switch cutting tools for various operations.1. The Turret Body. This is the main principle framework of the tool turret. The turret body houses the apparatus for managing tool clamping, tool indexing, and rotation. It is found on the CNC machine tool holder giving it flexibility to move .

Learn about the common types of CNC tool turrets: BMT, VDI, and BOT, and their features, benefits, and applications. Compare their tooling capacity, rigidity, versatility, and cost-effectiveness for different machining . The BMT turret, an acronym for Base Mount Turret, is a specialized machine tool turret for CNC lathes that stands out due to its unique design and functionality. BMT tool holders boast a unique design that allows .CNC turret lathes utilize computer-generated G-code instructions to control the spindle speed, feed rate, and movement of the turret. The controller interprets these G-codes and directs the CNC turret lathe to carry out the desired .There are two principal types of turret lathes: 1. The Ram Type 2. The Saddle Type. Some of them are given below: Regarding the kind of blank or stock to be processed, turret lathes are divided into bar and chucking machines. As to size, turret lathes are classified as small (bar capacity d = 25 mm, chucking capacity D = 320 mm), medium (d = 80 mm, D = 500 mm) and .

turret lathe machine diagram

The VDI (VDI Tool Holder Interface) turret is a versatile type of turret commonly used in CNC machines. It features a quick-change tool holder system that allows for easy and rapid tool changes. The VDI turret is highly adaptable, enabling businesses to rapidly switch between different tools for various machining operations. This type of turret .

The BMT turret is a type of CNC machine tool turret that is attached to the machine spindle by a base mount. It has a radial orientation and typically has six, eight, ten, or twelve tool stations. BMT turrets are known for their ruggedness and precision.Section 2: Types of CNC Machine Turret Assembly (200-250 words)\ Here, we will explore the different types of CNC machine turret assemblies available in the market. We will discuss the characteristics, advantages, and limitations of each type, including disc-type, ram-type, and indexable turret assemblies. This section will help readers .

Turret CNC centers come in a variety of types, each with its own unique features and applications. Understanding the differences between these types of machines is essential for selecting the right machine for a particular application. Whether you are creating large, complex parts or small, precise components, there is a turret CNC center that is right for your needs.Slant Bed CNC Lathe / Flat Bed CNC Lathe. On some CNC lathe machines x-axis carriage with the tool turret is located behind the spindle (such cnc lathe machines are called slant bed cnc lathe machines) and on other cnc lathe it is located at the front (as normal lathe machines) such cnc lathe machines are called flat bed cnc lathe machine.. The below is a Slant Bed CNC .Types of Tool Turrets . There are several basic types of tool turrets. Crown turrets have an indexing face and an axis of rotation that is angled to the tool turret’s mounting surface. They hold live tooling machine tools, such as drills, that are driven or rotated. Most crown turrets are used in high performance, mass production machining. To better navigate an object, having basic knowledge regarding its background (such as – what it is, its purpose, types, and outcomes) is important. CNC Machines, such as CNC Lathes, are required to be programmed to produce results. These machines can be programmed in two ways – either by using the CAD/CAM system or directly [.]

tool turret for cnc lathe

Hartness 3x36 flat turret lathe with cross-sliding head, equipped for bar work, 1910 [1]. A turret lathe is a form of metalworking lathe that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually interchangeable.It evolved from earlier lathes with the addition of the turret, which is an indexable toolholder that allows multiple cutting .

Vertical Milling Machine EWS KOREA has been established as a joint-venture corporation with EWS the world-famous tool-holder manufacturing company in Germany,to strengthen the compet.

stainless steel bread box walmart

Here are 12 of the most common types of CNC machines. Each performs somewhat different machining operations with few human errors, high-speed processes, and high-quality results. 1. CNC Milling Machine. CNC milling machines use rotating cutting tools to remove material from a workpiece. The primary 3-axis CNC machines move along an X-axis (side . Lathe Turret Types and Tooling . we are forced to place the maximum number of processing tools in the CNC machine's working zone. Lathe manufacturers have always sought to maximize the number of turning tools available and the speed at which they can be changed. Universal lathes typically utilize quick-change toolholders that can accommodate .

Study with Quizlet and memorize flashcards containing terms like Which type of turning center is the least suited for high-volume production?, An operator should not remove bypass guards on a CNC machine., The biggest disadvantage of vertical milling centers is their ____. and more. The CNC lathe turret is controlled by the CNC machine’s computer, which sends signals to the motor to rotate the turret and bring the appropriate tool into position. . What types of tools can a CNC lathe turret .Tool turret: The tool turret is the part that holds the cutting tools that are used to shape the workpiece. It is attached to the cross slide and can be turned to position different tools. . These types of CNC machines use electrical .

This arrangement is often used on saddle-type machines to be used for large diameter chucking operations. In another arrangement, the cross-slide is mounted on both upper bed-ways and further supported by lower-ways. . This NC and CNC automatic turret lathe mechanically replaced the automatic turret lathe and manual turret lathe but not . Turret of cnc lathe machine. Turret meaning. It’s a tool station which can index any tool for operation.It’s clamp and unclamp are controlled by hydraulic. . Type of Piston Pump Description Advantages Applications Single Acting Piston Pump Moves the piston in one direction, creating suction and discharge strokes. . The turret lathe is a type of metalworking lathe machine that developed from earlier lathes, adding a turret, which is a kind of indexable tool holder, allowing to perform multiple cutting operations on one machine with different tools, without the need for the operator to do set-up works or control the toolpath. . CNC Turret Lathe: equipped .

numerical control turret punch press

A turret lathe is a type of machine tool overhang handy for metalworking. It has specific designs to perform a range of operations on a workpiece, such as turning, drilling, boring, and threading. . CNC turret lathes’ lightweight, indexable automatic tool holder allows different cutting tools, optimizing machining processes. . CNC machines are modern subtractive manufacturing equipment, which automatically control the tool path and movement for material removal. You can find different types of CNC machines in industrial factories and the CNC Machine Shop, each with specific manufacturing purposes.However, all of them are used to craft the blank work material into the .

CNC tool holders, including turret, power, and static types, secure cutting tools for precision and stability in machining. They ensure quick tool changes and are essential for various industrial applications. . For CNC machines to function properly, apart from the hardware and software, the most crucial component is the CNC tool holder. CNC . 1. Classification based on the machine tool’s motion trajectory According to the different motion trajectories of the machine tool, it can be divided into point-to-point control CNC machine tools, linear control CNC machine tools, and contour control CNC machine tools. (1) Point-to-Point Control CNC Machine Tools. Point-to-point control (also known as positioning .A. basic CNC lathe B. gang-tool lathe C. turret lathe D. swiss-type turning center. A. For a basic CNC lathe, tooling changes are done by the _____. operator. . They are not suitable for high-volume production They cannot match the capabilities of more advanced CNC machines.In summary, a CNC lathe turret is indispensable for modern precision machining, offering rapid tool changes, increased productivity, and improved precision. Types of Turrets in CNC Machines. Turrets in CNC machines come in various types, each designed to improve efficiency and precision in different machining operations.

gang tooling vs turret lathe

cnc turret punching machine

Study with Quizlet and memorize flashcards containing terms like Name the two primary machine axes on most CNC turning machines., Explain the difference between a turning center and a CNC lathe., List the three common types of live toolholders. and more. . Turret-type machines, gang-tool-type machines, Swiss-type turning center.

cnc turret punch press machine

Click here to view a list of U-Line product accessories. Are you a U-Line Service Provider? Click here to order U-Line parts. Looking for information on Nugget Ice Machine in-line water filters? Click here to learn more.

types of turret in cnc machine|numerical control turret punch press