creo sheet metal Sheet metal parts are solid models that can be represented in either sheet metal . The Hobart Handler 140 is an excellent choice for sheet metal welding due to its versatility and user-friendliness. With an amperage range of 25 to 140A, it’s capable of handling various thin materials, including sheet metal.

0 · sheet metal in creo parametric

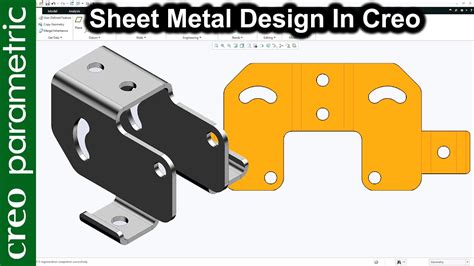

1 · sheet metal design in creo

2 · creo sheet metal tutorial pdf

3 · creo sheet metal tutorial

4 · creo sheet metal roll bend

5 · creo sheet metal basics

6 · creo parametric sheet metal tutorial

7 · creo convert to sheet metal

Industry leading metal fabrication in Sparta, MI. C&T specializes in stainless steel fabrication, laser cutting, process piping & material handling.

Under Sub-type click Sheetmetal. 4. In the File Name box, type a name for your new sheet metal part. 5. If you want to use the default template, click OK. a. Clear Use default template and .

Creo Elements/Direct Sheet Metal creates a new 3D sheet metal part. Options .

This method of working with sheet metal is to create the model within sheet metal .Sheet metal parts are solid models that can be represented in either sheet metal .Learn how to create a sheet metal part by using a workplane, a polyline, a solid, or a closed outline. Specify the material, the thickness, the bend radius, and the side of the sheet metal part.

Learn how to use the Convert to Sheet Metal tool in Creo Parametric to create a sheet metal part from a solid part. Follow the steps for different options: Driving Surface, Shell, or Empty Body. In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange . sheet metal in creo- tutorial 1planer command in creo parametric PTC Creo Parametric 9.0 Basic Sheet Metal Tutorial For Beginner. This tutorial is designed for beginners who have basic knowledge of PTC Creo Parametric 9.0..

sheet metal in creo parametric

This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell .Sheet metal parts are solid models that can be represented in either sheet metal form or as a flat model. These parts are of uniform thickness and can be modified by adding features. Features .1: Introduction to the Creo Parametric Sheetmetal Design Process. 2: Sheetmetal Model Fundamentals. 3: Creating Primary Sheetmetal Wall Features. 4: Creating Secondary .

sheet metal design in creo

Check out this video on Creo Sheetmetal Design from PTC Application Engineers Presenters: Lino Tozzi (Technical Specialist, Fellow) and Tom Quaglia (Creo Segment Sales ). . Thank you for the response, unfortunately, Creo does not have the same menus. I am also trying to avoid family tables for sheet metal as it would require a separate part. We would like one part number/name for the drawing and the sheet metal component.

If possible model your part in part mode, not sheet metal mode. You can then convert the part to sheet metal, in many cases this is a more efficient way to create parts in Creo. It is much faster to create the geometry in part mode for many parts. As you have found flange is not the tool that will yield the result you want in your example model. In Creo 1, to create the 3d flat pattern - go to File, Prepare, Model Properties. Under Shett Metal, change the Flat State Instances and create a family table flat pattern tied to the shett metal part. In WF5 this was under Edit , Setup. For Creo 2, it will be in the floating tool bar at the top of the modeling view.

Is it possible to mirror half of a sheet metal part? We often create solid parts in half, copy solid geometry, mirror the quilt, and solidify the quilt. Is there a way to do something similar to this with a sheet metal part? It seems that the solidify tool only wants to cut material away in a sheet metal part. Creo 10 Flat Pattern a sheet metal Blend part that does not have constant radius. Hi all, I have been searching the forum, and could not find the same issue, similar, but not same. This is a straight forward part that I am trying to get flat, any ideas how to do it? I am into the filed of creo Automation using Toolkit. I am into sheet metal group. For thickness of the part, is it okay to go with the assumption that thickness of all features inside a part tree (Flange, Flat, Extrude etc.) remains constant? If not so, It will be better to have some example of varying thickness. Regards. Ketan

I am working in Creo Elelements / Pro. Thanks. Niels M. M. This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question.In Creo Parametric 4.0 Sheetmetal Design, you can use flexible modeling to edit the corner seams of a sheet metal part independent of how the part was created, even if it was imported from another CAD system. You can change parameters and controls in the mini toolbar or in the ribbon. The mini toolbar opens when a corner seam is selected. In this tutorial, you can learn How to use Sheet Metal Conversion modelling technique in ProE or with same logic in Creo Parametric. This video was created based on question from a comment under my video on YouTube channel. Fell free to contact me or leave a comment, or idea for another Creo tuto.

There's also some rarely used features in sheet metal and a practically UNKNOWN feature in regular Pro/E that can help with bended tabs. One of my all-time favorite forgotten Pro/E features is the EAR. Thank you for the response, unfortunately, Creo does not have the same menus. I am also trying to avoid family tables for sheet metal as it would require a separate part. We would like one part number/name for the drawing and the sheet metal component. If possible model your part in part mode, not sheet metal mode. You can then convert the part to sheet metal, in many cases this is a more efficient way to create parts in Creo. It is much faster to create the geometry in part mode for many parts. As you have found flange is not the tool that will yield the result you want in your example model.

18 x 72 metal insert for flower box

In Creo 1, to create the 3d flat pattern - go to File, Prepare, Model Properties. Under Shett Metal, change the Flat State Instances and create a family table flat pattern tied to the shett metal part. In WF5 this was under Edit , Setup. For Creo 2, it will be in the floating tool bar at the top of the modeling view.

Is it possible to mirror half of a sheet metal part? We often create solid parts in half, copy solid geometry, mirror the quilt, and solidify the quilt. Is there a way to do something similar to this with a sheet metal part? It seems that the solidify tool only wants to cut material away in a sheet metal part. Creo 10 Flat Pattern a sheet metal Blend part that does not have constant radius. Hi all, I have been searching the forum, and could not find the same issue, similar, but not same. This is a straight forward part that I am trying to get flat, any ideas how to do it? I am into the filed of creo Automation using Toolkit. I am into sheet metal group. For thickness of the part, is it okay to go with the assumption that thickness of all features inside a part tree (Flange, Flat, Extrude etc.) remains constant? If not so, It will be better to have some example of varying thickness. Regards. Ketan

I am working in Creo Elelements / Pro. Thanks. Niels M. M. This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question.

In Creo Parametric 4.0 Sheetmetal Design, you can use flexible modeling to edit the corner seams of a sheet metal part independent of how the part was created, even if it was imported from another CAD system. You can change parameters and controls in the mini toolbar or in the ribbon. The mini toolbar opens when a corner seam is selected. In this tutorial, you can learn How to use Sheet Metal Conversion modelling technique in ProE or with same logic in Creo Parametric. This video was created based on question from a comment under my video on YouTube channel. Fell free to contact me or leave a comment, or idea for another Creo tuto.

creo sheet metal tutorial pdf

Screwdriving tools from Wera are tools from and for Tool Rebels. We at Wera firmly believe that we can always question existing standards. We want to make the screwdriving experience ever simpler, safer and full of joy.

creo sheet metal|sheet metal in creo parametric