cnc machine abilities CNC milling is a precision machining process that uses computer-controlled rotary cutting tools to remove material from a workpiece, creating custom shapes and features as programmed by a CNC machinist. Truck Bed Repair Panel, Front Bed Panel, Steel, Galvanized, Original Design, Ford, Each. Part Number: MRK-120101. Not Yet Reviewed

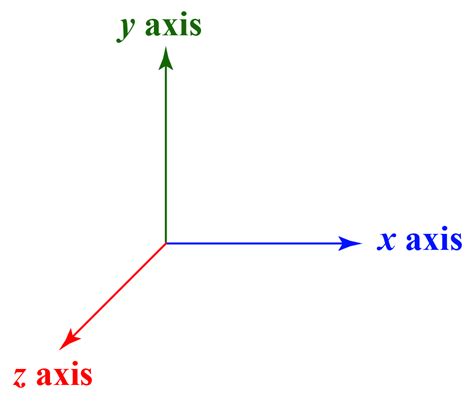

0 · how many axis are there

1 · how does cnc machine work

2 · high end cnc machines

3 · cnc mill axis diagram

4 · cnc machining guide

5 · cnc machine how it works

6 · cnc machine advantages and disadvantages

7 · 5 axis vs 6 cnc

Locking T-handle latches provide maximum security while using minimum space; Two rear support legs offer greater stability for mounting to vehicle; Reinforced metal lid brace adds strength and durability; Smooth finished edges; Dual door styling for easy access; Door cables prevent over-extension of the doors

CNC machinists must possess a deep understanding of technical drawings and specifications, alongside proficiency in the operation and programming of key CNC machine tools like lathes, mills, drill presses and advanced software.

lost planet extreme condition steel box xbox 360 front

Understand the duties and responsibilities of a CNC machine operator. Acquire the necessary skills, training, and certifications for success in the field. Explore the various career opportunities available for CNC machine . The profession of CNC Machinist or CNC Machine Operator is a highly skilled one that is exposed to technically challenging work. It can open up a wide spectrum of opportunities such as: programming, product design, quality . Learn what skills your peers have and what skills you need to get ahead as a CNC Machinist or CNC Machine Operator.

CNC milling is a precision machining process that uses computer-controlled rotary cutting tools to remove material from a workpiece, creating custom shapes and features as programmed by a CNC machinist.CNC operators play a crucial role in maintaining the quality standards of finished products. They inspect each part produced by the CNC machine, using measuring tools and devices to check dimensions and tolerances. Computer numerical control (CNC) machinist skills are specific abilities that enable you to operate, control, and maintain CNC machines effectively in high-demand manufacturing .

CNC machinists are important in making things for industries that need very accurate parts, like cars, planes, and medical equipment. CNC machinists set up and run the machines based on .

CNC machinists must possess a deep understanding of technical drawings and specifications, alongside proficiency in the operation and programming of key CNC machine tools like lathes, mills, drill presses and advanced software.

Understand the duties and responsibilities of a CNC machine operator. Acquire the necessary skills, training, and certifications for success in the field. Explore the various career opportunities available for CNC machine operators. Prioritize safety in CNC machine operation to ensure a secure work environment.

CNC operator skills are a combination of technical and interpersonal abilities that you can use to bring a creator's or engineer's design to life. Like any other job, these skills can be divided into hard and soft skills, each equally essential for a well-rounded CNC operator. The profession of CNC Machinist or CNC Machine Operator is a highly skilled one that is exposed to technically challenging work. It can open up a wide spectrum of opportunities such as: programming, product design, quality control, and planning. Learn what skills your peers have and what skills you need to get ahead as a CNC Machinist or CNC Machine Operator.

CNC milling is a precision machining process that uses computer-controlled rotary cutting tools to remove material from a workpiece, creating custom shapes and features as programmed by a CNC machinist.CNC operators play a crucial role in maintaining the quality standards of finished products. They inspect each part produced by the CNC machine, using measuring tools and devices to check dimensions and tolerances.

Computer numerical control (CNC) machinist skills are specific abilities that enable you to operate, control, and maintain CNC machines effectively in high-demand manufacturing and fabrication industries.CNC machinists are important in making things for industries that need very accurate parts, like cars, planes, and medical equipment. CNC machinists set up and run the machines based on specific instructions, and they make sure everything is cut or shaped exactly right.A CNC machinist is a skilled professional operating CNC machines to manufacture precision components and parts. Based on computer-generated instructions, these machines can execute highly precise movements and cuts on various materials.CNC machinists must possess a deep understanding of technical drawings and specifications, alongside proficiency in the operation and programming of key CNC machine tools like lathes, mills, drill presses and advanced software.

Understand the duties and responsibilities of a CNC machine operator. Acquire the necessary skills, training, and certifications for success in the field. Explore the various career opportunities available for CNC machine operators. Prioritize safety in CNC machine operation to ensure a secure work environment.

CNC operator skills are a combination of technical and interpersonal abilities that you can use to bring a creator's or engineer's design to life. Like any other job, these skills can be divided into hard and soft skills, each equally essential for a well-rounded CNC operator.

how many axis are there

The profession of CNC Machinist or CNC Machine Operator is a highly skilled one that is exposed to technically challenging work. It can open up a wide spectrum of opportunities such as: programming, product design, quality control, and planning. Learn what skills your peers have and what skills you need to get ahead as a CNC Machinist or CNC Machine Operator.CNC milling is a precision machining process that uses computer-controlled rotary cutting tools to remove material from a workpiece, creating custom shapes and features as programmed by a CNC machinist.

CNC operators play a crucial role in maintaining the quality standards of finished products. They inspect each part produced by the CNC machine, using measuring tools and devices to check dimensions and tolerances. Computer numerical control (CNC) machinist skills are specific abilities that enable you to operate, control, and maintain CNC machines effectively in high-demand manufacturing and fabrication industries.CNC machinists are important in making things for industries that need very accurate parts, like cars, planes, and medical equipment. CNC machinists set up and run the machines based on specific instructions, and they make sure everything is cut or shaped exactly right.

how does cnc machine work

$116.09

cnc machine abilities|how many axis are there