how to splice a wire too short for junction box In this electrical DIY guide i will be showing you how to extend short cable. I will take you through step by step, showing you how to splice cables the easy. One crucial aspect of operating CNC machines is understanding the file formats they utilize. In this article, we will explore the various types of files CNC machines use and delve into their significance in achieving optimal machining results.What are CNC files? CNC files are digital blueprints that CNC machines use to carve, cut, or mold material. They contain specific instructions that guide the machine on how to produce a particular design. Why is the file .

0 · wire splice kit behind drywall

1 · splicing romex without a box

2 · splicing electrical wires behind walls

3 · splice kit approved for walls

4 · romex 2 wire inline splice

5 · install floodlight without junction box

6 · extend electrical wiring without replacing

7 · approved in wall wire splice

Metal electrical boxes typically require screws with threads that can securely grip the metal surface, while non-metallic or plastic boxes may have specific screw requirements to prevent cracking or damage.

wire splice kit behind drywall

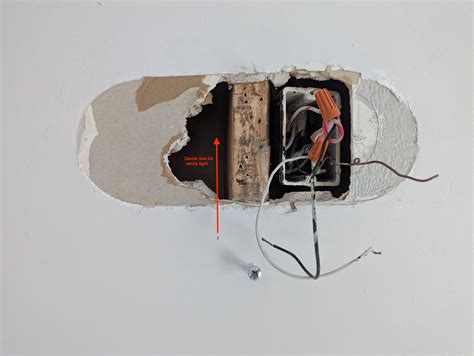

Wire that short can't be spliced or extended. The wire must be able to come out beyond the surface of the box at least 3". You will need to reroute these cables to a different junction box somewhere the wiring is able reach with the needed spare length inside the box.Don’t let short electrical wires cramp your DIY project. Splice in extra wire in a few .You're going to need to either pull new cable from the nearest outlet/junction . In this electrical DIY guide i will be showing you how to extend short cable. I will take you through step by step, showing you how to splice cables the easy.

Don’t let short electrical wires cramp your DIY project. Splice in extra wire in a few seconds using easy push-in connectors. Electricians should leave at least six inches of wire in wall boxes, which will provide enough . WAGO 221-413 or the 221-2401 make quick work of extending short wires to reach a new breaker location in your electrical panel. If you do not feel safe performing this work yourself please call.When the cables and junction box are installed and in place, make your splices (ground to ground, white to white, and black to black) using approved wire connectors. Cover your junction box with the appropriate blank cover plate.

You're going to need to either pull new cable from the nearest outlet/junction box on that circuit, which will not be easy since this is obviously NM cable, presumably stapled (as it should be) to studs along the way, or you're going to . Wrap one of the bare copper ground wires once around the grounding screw that’s attached to the junction box; you should leave about 6 inches of exposed wire hanging past the screw. To complete this method, the steps you need to follow include: First, unplug the device that contains the wires you are going to be splicing. If the wire is attached to the wall and cannot be unplugged, always turn off the circuit. . The method demonstrated here is the correct way to splice electrical wires using UL-approved wire connectors joined inside an approved electrical box. These connectors can be the familiar twist-on wire nuts or .

Wiring problems and mistakes are all too common, and if left uncorrected have the potential to cause short circuits, shocks and even fires. Here's what to look for and how to fix what you find.This could be accomplished with soldering and shrink wrap, correct use of twist-on caps with proper strain relief, or a variety of other splicing techniques. The problem is too many people don't splice correctly, so code does not allow . All My Favorite Tools: https://www.amazon.com/shop/everydayhomerepairsWAGO 221-413 or the 221-2401 make quick work of extending short wires to reach a new br.

Conclusion: How to Splice a Single Gang Junction Box. A Single-Gang Box, a Junction Box, a One-Device Box.. whatever you want to call it.. that’s how you splice wires in an electrical box! You start by removing the wire .For example, I had to rework some of the garage circuit, so I move those splices to a separate junction box a foot away and ran fresh Romex between the two. Throw up a sticker with the circuit number on the box and wammo, all three garage splices are in the same box, and the load center is still nice and neat and organized. –

I totally understand since it is not code, an electrician cannot perform the work. I traced the wiring back to the fixture, and it would be a major project to get the fixture rewired so that the wire would be one going from fixture to junction box. If I were to purchase the same wire & ground wire, can this be done safely, or is there a risk.

(a) Buy a new set of longer wires for about . (b) Place a junction box () just outside the tub and buy 3FT of wire ().

However, the existing Romex is too short to comfortably be threaded through a hole in the stud/shim and into the fan box on the other side. I was going to leave the old box in place, using it as a pure junction box (no fixture/switch/outlet) and running a short length of Romex from this box, through the stud/shim, to the fan box on the other side.

Make the connection at the existing junction box, place a blank cover per previous answer. This is why I asked all the questions before, The approved splice kit is not for removing a junction box so you can hide the connection in the wall. You would attach the new wire at the existing light fixture and extend it to the new location.I like your solutions. An additional one - although admittedly not ideal - is to cut another hole above (or below depending on the cable's routing), install a switch box with the Romex running into it, join the Romex with a longer, new piece of Romex, place a blank plate to cover the new switch box, and run the new, longer length into the original box and terminate like normal. Making junction boxes for less than 2 dollars (assuming you have the tools and wire nuts/push connectors already) :-) ---This is a re-upload where at the en.ITEMS I USED ON THIS VIDEO:- WAGO Wire Connectors (36 Pieces) - https://amzn.to/3l38lmA- WAGO Wire Connectors (75 Pieces) - https://amzn.to/3PhsmDS- WAGO Wir.

So if the existing wire has 2 feet of slack from the wall, I'd cut the opening for the new box 18 inches up the wall. Pull the existing wire up through the j-box opening and at the same time run 5 or 6 feet of new wire down from the j-box opening, through the existing hole in the wall. Mount new j-box once you've pulled both wires into it.

splicing romex without a box

The new box I'm looking at is 28.7 in tall. This will put it too close to the ground since our old box is only 13 in tall and the bottom is 18 in from the ground (pictures below) and NEC 550.32(F) requires that the bottom of the load center be 24 inches from the ground. Exposed splices are not code compliant, no. All splices need to be made inside a junction box or fixture. In this case, what Ed Beal is suggesting is to simply clip your current wire as close to the fixture as possible, and make the splice inside the body of the new fixture.

As far as I can tell the box is placed as low as permissible (4' per Duke install guidelines). The most frustrating part is the seeming lack of comms. Any information we've received is via generic text or the call center folks and that . Installing a Tyco Electronics no junction box splice connector.https://www.grainger.com/category/electrical/electrical-supplies/wire-connectors/non-metallic-. I thought of RMC conduit (6" cover) to cut the corner (/foot), or using double-size conduit bodies as junction boxes (-50 each). But then, I realized you're going to need six rather expensive Polaris connectors for this . Before you do anything, find the main breaker box in your home. Then, locate the breaker switch that provides power to the junction box you want to work on. Once you have located the correct switch, set it to the 'off' position. Step 2 - Open the Junction Box. Use the screwdriver to remove the screws from the cover plate on the junction box.

The term ‘Splice’ specifically refers to that point where two lines join. Most DIY fanatics have performed a wire splice at least once during their lifetime. Although, they probably began with thinner wires. Ultimately, there is no limit to the thickness of the wires you can splice. In fact, there’s no such thing as a wire that is too thick. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . Maybe you should, if the wire length allows. Or even if not, wire isn't that expensive. The important part is to use aluminum wire, which is far less costly and performs just as well in these large sizes. Terminals on the meter pan, main breakers and panels are all rated for aluminum (made of aluminum).

The wire must extend at least 3 inches beyond the front of the box. Options to Lengthen the Wires: Option 1: Check for extra wire or a service loop behind the box. Gently pull on the wires using pliers to draw more length into the box if available. Option 2: Access the cable feeding into the junction box via attic, basement, or crawl space. I always bring in short pieces of wire for this purpose. Just wirenut a piece of the same size wire on, . I will use the old panel(or Junction box) to splice all branch circuits to the new panel so the ground for each circuit will separately connected or we can have all ground tied together with the junction box? . A bit too provocative for .even though it is just a communication wire, my personal belief is that all connections should be inside a strain-relieved, water-tight junction box. you never know when the next yay-hoo will look at the connection on each end and say "these are all 14 AWG, one wire is as good as another" and wire it up to be hot. you also never know where water could get in or someone yanks on .

The existing wiring to a proposed new water heater will come up about 2-3 feet short. The way it's currently run it offers zero slackage to work with. There is no easy shorter route to rerun the existing wiring to get any additional length. Can some sort of junction box be installed in order to gain the required length that will be needed? This is in an unfinished basement area .

This will show you how to wire cables in a junction box. Pay attention what gauge wires you are splicing together. In the video I have both 12 AWG and 14 AWG. Electrical - AC & DC - Lengthen Existing Wire Without Junction Box - When we built our house a few years ago the electrician ran a wire to a junction box in our basement ceiling because we thought we were going to want a floor outlet in the living room on the main level. We haven't needed it because of the way our

1980 dukes of hazzard metal lunch box

Metal electrical boxes have been in use for a long time and offer distinct advantages over their plastic counterparts. Here are some reasons to consider using metal boxes: Superior Strength and Durability: Metal boxes are incredibly strong and resistant to damage.

how to splice a wire too short for junction box|install floodlight without junction box