k factor sheet metal calculator K-factor Calculator for Sheet Metal Bending. K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness. weather proof boxes; junction boxes; Junction Boxes. ALL PRICES EXCLUDE VAT UNLESS OTHERWISE STATED. 6 Items Found. Reference, A to Z. Reference, A to Z Relevance New products first Name, A to Z Name, Z to A Price, low to high Price, high to low In stock Random . 6 Items per Page .

0 · sheet metal k factor table

1 · sheet metal flat pattern calculator

2 · sheet metal calculation formula

3 · k factor sheet metal chart

4 · k factor calculator online

5 · blank size calculator sheet metal

6 · bending calculation for sheet metal

7 · bend allowance k factor chart

Find your waterproof junction box easily amongst the 307 products from the leading brands (WISKA, TAKACHI Electronics Enclosure, MARECHAL ELECTRIC, .) on DirectIndustry, the industry specialist for your professional purchases.

This K-factor calculator will assist you in finding the K-factor for sheet metal. Sheet metal is the building block of structures, from forming the body of automobiles to the skin of aircraft wings.K-factor Calculator for Sheet Metal Bending. K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness.

The SkyCiv K-Factor for Sheet Metal is a free tool designed to help engineers and fabricators understand the effects of their sheet metal bending designs.Looking for a quick and easy way to calculate the K factor and bend allowance for your sheet metal? Our online calculator is your go-to tool! The K factor is a crucial parameter in sheet .This calculator is particularly useful for engineers, fabricators, and designers who work with sheet metal. By accurately determining the K-Factor, you can ensure precise bending, avoiding .

How to calculate bend allowance, K factor and Y coefficient in one click. To calculate the bend allowance, the K factor and the derived coefficient called the Y factor, insert the thickness and .Our K-Factor Calculator helps you compute the K-factor for your sheet metal projects, ensuring precise bending and fitting. Bend Allowance (inches or mm): Enter the bend allowance value, .

K Factor Calculator for Sheet Metal Bending (Online & FREE) Are you struggling to design accurate sheet metal parts? Unlock the secrets of the K-factor, a crucial concept in sheet metal fabrication.

The K Factor calculator streamlines the process of calculating the required flat length for a bend, making it an indispensable tool for professionals in the sheet metal . The K factor is a key metric in many fields like statistics, engineering, and manufacturing. This article will explore what the K factor is, how it’s calculated, and its uses. It’s important for data analysts, electrical .How to calculate bend allowance, K factor and Y coefficient in one click. To calculate the bend allowance, the K factor and the derived coefficient called the Y factor, insert the thickness and initial length of the sheet into the cells on the left.After bending the sheet, insert the inner radius, and flanges A and B. Bending angle is 90°.

Use one of the listed K-Factor calculators and measurement of a sample bent part: K Factors Autodesk Inventor; Inventor K Factor Calculator; Manually calculate the K-Factor using the measure of sample sheet metal .

The K-Factor Calculator is a handy tool designed to assist in determining the K-Factor of sheet metal for various bending operations. The K-Factor is a crucial parameter in the world of metal fabrication, influencing how material stretches and compresses during bending.K Factor Calculator for Sheet Metal. Length A . K Factor Calculator - Factor Calculator. document.getElementById('result').innerHTML = ` Price: Free Price Currency: $ Operating System: Browser, Windows, Android Application Category: .The mold line lengths are the distances measured to the outside mold line and are equal to the flange lengths plus the setback. The values of the setback, bend allowance, and bend deduction can be calculated from the sheet thickness, bend radius, bend angle, and .The K-Factor in sheet metal working is the ratio of the neutral axis to the material thickness. When metal is bent the top section is going to undergo compression and the bottom section will be stretched. The line where the transition from compression to stretching occurs is called the neutral axis. The location of the neutral axis varies and .

Application of K Factor in Sheet Metal Bending. The K factor plays a crucial role in sheet metal bending, as it affects the bend allowance and bend deduction. Proper calculation of the K factor ensures that the final dimensions of the sheet metal part meet the specified tolerances and requirements. Bend Allowance

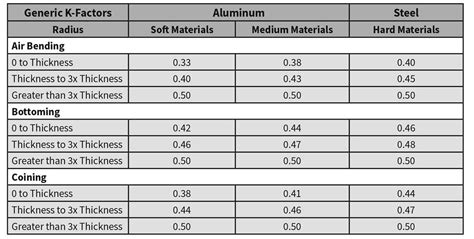

What is K-Factor in Sheet Metal Bending? . By using the bending calculator, you can save yourself days of headache and redesigns with just a few seconds of preparation. Simply input your material, chosen thickness, and flange and base length, and the calculator will do all of the work for you. Again, make sure to utilize this tool before .Our online calculator is your go-to tool! The K factor is a crucial parameter in sheet metal bending, but it can be tricky to determine. It depends on factors like material, thickness, inner radius, and bend angle. We've created a comprehensive guide to explain the K factor, its formula, and its implications. Simply input your material . K-Factor is the ratio of the neutral axis to the material thickness. Many designers reference a chart like this or use test pieces to calculate the K-Factor for specific projects. SOLIDWORKS defaults to calculating the flat pattern using the K-Factor.

BendWorks is a simple calculator to help you calculate bend deductions, and to help you reverse engineer the best K-factor to use when creating sheet-metal parts in you favorite CAD program. It also includes a set of default "rule of thumb" K-factors to use for various materials, radii, and bending methods.

So, now you have a formula for the BA—but where’s the k-factor? It’s hiding in that 0.0078 value, which is π/180 × k-factor. To arrive at 0.0078, the equation uses a k-factor of 0.4468, a commonly used factor that’s the default .

Finding K factor , bend deduction and bend allowance is very important for a sheet metal work shop. All you have to do is get a sample flat size and then fold it as per your press break. After that you need to measure following data using .The K Factor Calculator is a vital tool in the field of metalworking, particularly in sheet metal fabrication. It is used to determine the K Factor, which is a critical parameter in the process of bending metal sheets.Understanding the K Factor helps in accurately predicting the flat pattern size of a bent sheet metal part, ensuring precise and efficient manufacturing. The K-factor is determined by the physical properties of the material, bending method, bending angle, and other factors. Material Properties: it typically ranges between 0.30 and 0.50.In general, the K-factor of soft copper or soft copper materials is 0.35, the K-factor of materials such as semi-hard copper or brass, mild steel and aluminium is 0.41, and the K .

The K-Factor can be calculated using the following formula: K-Factor (K) = (Distance from Inside Radius of Bend (R)) / (Material Thickness (T)) Why is the K-Factor Important? Understanding the K-Factor is crucial because it helps sheet metal fabricators accurately predict the flat pattern length, which is vital for cutting the material to the . For instance, if the distance from the inside radius of the bend to the neutral bend line (D) is 5 mm and the thickness of the sheet metal (T) is 2 mm, the K Factor would be calculated as follows: \[ K = \frac{5}{2} = 2.5 \] Importance and Usage Scenarios. The K Factor is crucial in the field of sheet metal fabrication for several reasons. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! This tool calculates bend allowance/deduction based on material thickness, bend angle, inside radius, and k-factor, as you will learn from the bend .

The K factor is an important parameter used in sheet metal fabrication to calculate the flat pattern length of a sheet metal part. The K factor represents the ratio of the neutral axis to the material thickness and is used to calculate the bend allowance. To find the K factor in sheet metal, you can use the following steps: In sheet metal design, the K factor is a critical value that influences how the software calculates the bending allowance during the fabrication process. Essentially, the K factor is a ratio that represents the location of the neutral axis (the axis at which the material neither compresses nor stretches during bending) relative to the thickness . In order to simplify the definition of the sheet metal neutral layer and make it applicable to all materials, the concept of the K-factor was introduced. The definition of the K-factor is: it is the ratio of the thickness of the sheet metal’s neutral layer to the overall thickness of the sheet metal part material.

sheet metal k factor table

The sheet metal blank size is determined by considering factors like part dimensions, material thickness, bend allowance, stretch allowance, bend radius, minimum bend distance, material properties, K-factor, drawing ratio, setback, tooling, tolerances, part complexity, and material utilization efficiency. Accurate calculations ensure efficient use of material and .

BendCalc is a bend deduction and bend allowance calculator for sheet metal air-bending. Actually BendCalc is more than that, BendCalc is five calculators in one. . Calculator 4: Calculates the K-Factor given the bend angle, material thickness, radius and bend deduction. Calculator 5: .

brivano cnc machine

broken junction box

$7.09

k factor sheet metal calculator|sheet metal calculation formula