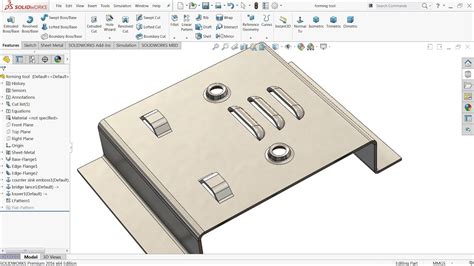

solidworks 2018 sheet metal Multibody sheet metal parts can consist of multiple sheet metal bodies or a . Channel (C-Shaped) Structural C channels, or C beams, have a C-shaped cross-section. Channels have top and bottom flanges, with a web connecting them. C-shaped beams are cost-effective solutions for short- to medium-span structures.

0 · solid work to sheet metal converter

1 · solid work to sheet metal

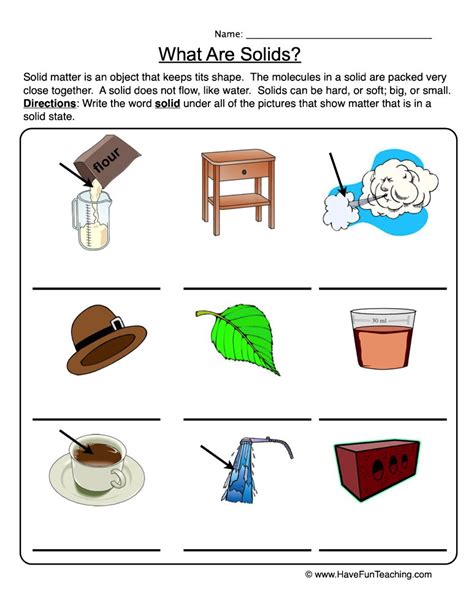

2 · solid to sheet metal worksheets

3 · convert solid to sheet metal worksheet

4 · convert solid to sheet metal

We have compiled a short breakdown of each of the grades’ properties in order to provide you with a brief understanding of their many uses. Alloy 1100: This grade is commercially pure aluminum. It is soft and ductile and has excellent workability, making it ideal for applications with difficult forming.

Contents. Comparing Sheet Metal Design Methods. Using Sheet Metal Tools. Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or .

Adding Sheet Metal Gussets. You can create sheet metal gussets with specific .

solid work to sheet metal converter

solid work to sheet metal

Multibody sheet metal parts can consist of multiple sheet metal bodies or a .You can calculate the developed length of sheet metal parts using bend calculation .There are specific sheet metal features you can use to create sheet metal bodies .Sheet metal gauge/bend tables store properties for a designated material. A .

SOLIDWORKS has specific sheet metal features that allow the creation of sheet .“Convert to Sheet Metal” allows the user to quickly convert parts into sheet metal .Download this model to learn more about new functionality added recently to .Sheet metal gauge/bend tables store properties for a designated material. A single table lets you associate a bend allowance, bend radius, or k-factor with any combination of thickness, bend .

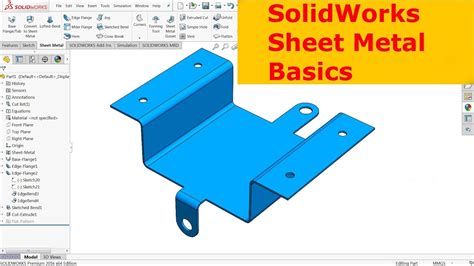

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. In this lesson, you create the sheet metal part. This lesson demonstrates: - Creating a base flange - Adding a miter flange - Mirroring the part and creating. SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. We can use these features to create .

SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of . “Convert to Sheet Metal” allows the user to quickly convert parts into sheet metal models, from there a flat pattern can be automatically created. This is a useful tool if the initial part has been created using standard part .SOLIDWORKS 2018 TUTORIALS Chapters Sheet Metal Part 1 Bottom...1-1 Sheet Metal Part 2 Top ...2-1 Sheet Metal Part 3 End...3-1

Download this model to learn more about new functionality added recently to SOLIDWORKS Sheet Metal to help speed up your design process and make you a more efficient modeler. Download the part here! SOLIDWORKS 2018 - Automate Tab & Slot for Sheet Metal Design. A new tool automates the creation of tab and slot features, minimizing your need to build costl.The Sheet Metal toolbar provides tools for creating and using sheet metal parts. Base-Flange/Tab: Forming Tool: Convert to Sheet Metal: Unfold: Lofted-Bend: Fold: Edge Flange . SOLIDWORKS 2018 SP05 To disable help from within .You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. . SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help .

solid to sheet metal worksheets

Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief ratio, and fixed entity) for the entire part. . SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help instead, .Sheet metal bend line notes is a text file located in install_dir\lang\language\bendnoteformat.txt. This file sets the format of the bend line notes. . Help Content Version: SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help instead, .> Sheet Metal > Sheet Metal Parts > Cutting Across Sheet Metal Bends. SOLIDWORKS Help Other versions: | Print | Feedback on this topic : Introduction: Administration: User Interface: SOLIDWORKS Fundamentals: Moving from 2D to 3D . SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help instead, .Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal.; In the PropertyManager, under Sheet Metal Gauges, set options if you want to use a gauge table:. Select Use gauge table.; In Select Table, select a gauge table to use, or click Browse and browse to a gauge table.; Under Sheet Metal Parameters: . Select a face as the .

There are specific sheet metal features you can use to create sheet metal bodies quickly. However, in some circumstances when the design requires certain types of geometry, you can use non-sheet metal feature tools, then insert bends or convert the part to sheet metal. . SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use .Duplicate a sheet metal body in a part by creating a linear or circular pattern, mirroring the body, or using the Move/Copy Body command. Contents. . Help Content Version: SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help instead, .

Sheet metal gauge tables store properties for a designated material. You can access the sheet metal gauge table from the PropertyManager while creating the base flange. . SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help instead, .

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .in a multibody sheet metal part, move the bodies to be merged to the same plane. For example, . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. . SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help instead, .SOLIDWORKS includes sheet metal-specific features so you can create a part as sheet metal without having to convert it to sheet metal. . Help Content Version: SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help instead, .The red dotted line is the sheet metal offset and the black dotted line is the bounding box offset. . Help Content Version: SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help.

When you insert the forming tool in a sheet metal part, the placement sketch is where you can dimension the forming tool in relation to existing geometry. . Help Content Version: SOLIDWORKS 2018 SP05 To disable help from within .In a sheet metal part, create a new configuration. In the FeatureManager design tree, do one of the following: Right-click Flat-Pattern and select Unsuppress. . Help Content Version: SOLIDWORKS 2018 SP05 To disable help from within .Sheet metal gauge/bend tables store properties for a designated material. A single table lets you associate a bend allowance, bend radius, or k-factor with any combination of thickness, bend radius, and material. . Help Content Version: SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help instead, .

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

convert solid to sheet metal worksheet

When you mirror features and bodies in a sheet metal part, many of the bends are mirrored as well. The only bends that are not mirrored are those that are normal to and coincident to the mirror plane; those bends are extended. . Help Content Version: SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help .Sketch a line on the face of a sheet metal part where you want to create the jog. Alternatively, you can select the jog feature before you create a sketch (but after you select a plane). . Help Content Version: SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help instead, .In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part. The software automatically selects the edges on which rips are applied.Click Sheet Metal Gusset (Sheet Metal toolbar) or Insert > Sheet Metal > Sheet Metal Gusset.; In the Sheet Metal Gusset PropertyManager, under Position, select:. The bend face or two planar faces that are adjacent to a bend. The edge to be used as a reference. This can be any linear entity in order to specify the alignment of the gusset.

SOLIDWORKS 2018, intermediate skills : expanding on solids, surfaces, multibodies, configurations, drawings, sheet metal, and assemblies Bookreader Item Preview remove-circle Share or Embed This Item. Share to Twitter. Share to Facebook. Share to Reddit. Share to Tumblr. Share to Pinterest .The sheet metal template contains the procedures you or your sheet metal manufacturing supplier use to manufacture the part. The template can include customized information such as material cost and thicknesses, cost of manufacturing operations, and manufacturing setup costs. . Help Content Version: SOLIDWORKS 2018 SP05 To disable .To facilitate costing of sheet metal parts or machined plate parts from machining templates, you can convert circular cut paths into drilled holes. . Help Content Version: SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help instead, .Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

In an open sheet metal part, click Hem on the Sheet Metal toolbar, or click Insert > Sheet Metal > Hem. In the graphics area, select the edges where you want to add a hem. . SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help instead, . Amazon.com: SolidWorks 2018 Step-By-Step Guide: Part, Assembly, Drawings, Sheet Metal, & Surfacing eBook : CADFolks, Bhatt, . • Learn basic tools available in Sheet Metal and Surface Environment • Create sheet metal drawings • Create complex shapes using .

convert solid to sheet metal

Typical metals used for roofing include steel, aluminum, copper, and zinc. The cost of metal roofing also varies on the specific material you use. Steel is the most popular and typically least expensive metal roofing option. It’s known for its strength and durability, often lasting for 30–50 years or more.

solidworks 2018 sheet metal|solid work to sheet metal