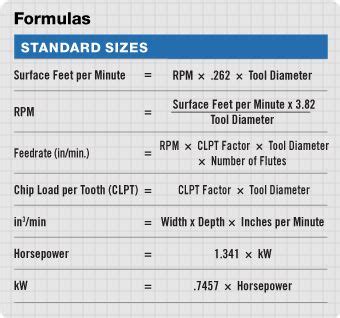

cnc machine design calculations Fz=hm * √(D/ap ) 1. Fz: Actual feed per blade 2. hm: theoretical feed per blade 3. ap:Z pitch(mm) 4. D: Blade diameter (mm) See more Shop for Carson Industries Water Meter Boxes & Lids at Ferguson. Ferguson is the #1 US plumbing supply company and a top distributor of HVAC parts, waterworks supplies, and MRO products.

0 · speed and feed calculator little machine shop

1 · milling speed and feed calculator

2 · milling cutter speed calculator

3 · high speed machining calculator

4 · cnc tool speed chart

5 · cnc machine calculator

6 · cnc feeds and speeds calculator

7 · cnc calculator free

$205.99

Vc=(πDS)/1000 1. Vc: linear velocity (m/min) 2. π: Circumference (3.14159) 3. D: Tool diameter (mm) 4. S: Rotational speed (rpm) See moreF=SZFz 1. F: Feed rate (mm/min) 2. S: Rotational speed (rpm) 3. Z: Number of blades 4. Fz: (actual feed per blade) See moreFz=hm * √(D/ap ) 1. Fz: Actual feed per blade 2. hm: theoretical feed per blade 3. ap:Z pitch(mm) 4. D: Blade diameter (mm) See moreT(min)=L(min)/N(rpm)*f(mm/rev)=πDL/1000vf 1. L: Full length of the drilling 2. N: Number of turns 3. f: feed volume factor 4. D: Bit diameter 5. v: Cutting speed Drill factor table fz See more

speed and feed calculator little machine shop

milling speed and feed calculator

Machine shop math is an important consideration for CNC programmers and machinists. One of the more common problems I have seen in my years in the machine shop is a general lack of .Online calculators for Basic Milling formulas. Radial and Axial Chip Thinning Calculators. Formulas and explanations for different cases. Get Chip Load recommendations per Raw . This paper proposes a method of designing an affordable, universal Computer Numerically Controlled (CNC) machine for the use by hobbyists and university laboratories.

CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, .

Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface . The CAM then converts the design into a G-code, the language understood by CNC machines. What are the criteria for designing CNC machine tools? Speed, stiffness, weight-bearing capacity, and tool life are the four .CNC machines commonly used to create the geometric shapes required by customers are vertical milling machines, horizontal milling machines, and lathes. To successfully make a part on a .

acrylic metal sheet

milling cutter speed calculator

add electrical box to closet

Calculators: In this section you will find a grown source for unique calculators that will help you design and build your CNC machine. Improve your CNC machining with our guide to commonly used calculation formulas. Get expert tips and optimize your processes now. The ultimate resource for understanding the 11 Common CNC Calculation Formulas. Essential for anyone involved in CNC machining.Machine shop math is an important consideration for CNC programmers and machinists. One of the more common problems I have seen in my years in the machine shop is a general lack of readily available and handy information on machine shop math – specifically on feeds, speeds and related formulae.

Online calculators for Basic Milling formulas. Radial and Axial Chip Thinning Calculators. Formulas and explanations for different cases. Get Chip Load recommendations per Raw Material and Milling cutter Diameter. vibration-free milling. CNC Gcode Program for all the main controllers configured with dozens of parameters.

This paper proposes a method of designing an affordable, universal Computer Numerically Controlled (CNC) machine for the use by hobbyists and university laboratories. CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, cutter type, and depth of cut, are taken care of at the machine shop, but there are some things you can do while designing your product to not only make sure it can be made, but also to .Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations.

The CAM then converts the design into a G-code, the language understood by CNC machines. What are the criteria for designing CNC machine tools? Speed, stiffness, weight-bearing capacity, and tool life are the four major factors you need to consider when designing CNC machine tools.CNC machines commonly used to create the geometric shapes required by customers are vertical milling machines, horizontal milling machines, and lathes. To successfully make a part on a CNC machine, programs instruct the machine how it should move.Calculators: In this section you will find a grown source for unique calculators that will help you design and build your CNC machine.

high speed machining calculator

Improve your CNC machining with our guide to commonly used calculation formulas. Get expert tips and optimize your processes now.

The ultimate resource for understanding the 11 Common CNC Calculation Formulas. Essential for anyone involved in CNC machining.

Machine shop math is an important consideration for CNC programmers and machinists. One of the more common problems I have seen in my years in the machine shop is a general lack of readily available and handy information on machine shop math – specifically on feeds, speeds and related formulae.

Online calculators for Basic Milling formulas. Radial and Axial Chip Thinning Calculators. Formulas and explanations for different cases. Get Chip Load recommendations per Raw Material and Milling cutter Diameter. vibration-free milling. CNC Gcode Program for all the main controllers configured with dozens of parameters. This paper proposes a method of designing an affordable, universal Computer Numerically Controlled (CNC) machine for the use by hobbyists and university laboratories. CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, cutter type, and depth of cut, are taken care of at the machine shop, but there are some things you can do while designing your product to not only make sure it can be made, but also to .

Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations. The CAM then converts the design into a G-code, the language understood by CNC machines. What are the criteria for designing CNC machine tools? Speed, stiffness, weight-bearing capacity, and tool life are the four major factors you need to consider when designing CNC machine tools.

CNC machines commonly used to create the geometric shapes required by customers are vertical milling machines, horizontal milling machines, and lathes. To successfully make a part on a CNC machine, programs instruct the machine how it should move.

add power from junction box

To ensure the optimal water-tightness for Scepter PVC Conduit connecting to PVC junction boxes (JB, JBX or JBXH), IPEX suggests two possible solutions: 1. Use of a Terminal Adapter (TA) with O-Ring Gasket, or 2. Use of Scepter Junction Box Adapter (JBA).

cnc machine design calculations|high speed machining calculator