electrical back box dimensions There is a huge selection of electrical boxes, varying by size, shape, mounting device, and composition. One of the first distinctions to note is that of new work boxes and remodel or cut-in boxes.

We develop turnkey solutions to enhance the CNC machine tools that you currently use. In today's manufacturing world, turnkey solutions that provide precision and efficiency are at the forefront of the success of your business.

0 · standard electrical box size chart

1 · standard electrical box size

2 · standard electrical back box dimensions

3 · electrical metal box size chart

4 · electrical box size chart

5 · electrical box dimensions standard

6 · electrical back box dimensions uk

7 · dimensions of electrical outlet box

Complete, Cost-Effective Metal Cutting and Custom Fabrication Solutions. Sawyer Fabrication’s upgraded water jet cutting system delivers both precision and versatility. If your fabrications require complex component designs and specialized materials, you’ve come to the right American metal shop.

Unlock the secrets of choosing the perfect back box size for your electrical installations. Dive into our guide to discover standard sizes, factors to consider, and practical tips for safety and functionality.Explore our in-depth guide on choosing the right back boxes for your electrical .Electrical Boxes vary in size, material, number of gangs, and shape and are designed for specific uses like junctions, outlets, and switch or fixture boxes for wiring in wall or ceiling. Use this . Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on .

NEC Article 314 covers Outlet, Device, Pull and Junction Boxes; Conduit bodies; Fittings; and Handhole Enclosures. It would go into uses approved and not approved for each particular box. I would suggest you get a .There is a huge selection of electrical boxes, varying by size, shape, mounting device, and composition. One of the first distinctions to note is that of new work boxes and remodel or cut-in boxes. These boxes allow you to add new electrical devices without affecting your drywall. Old work boxes are designed to be installed in finished walls, have tabs or clamps that grip the drywall from behind, and are available . Explore our in-depth guide on choosing the right back boxes for your electrical installations. From materials and sizes to weatherproofing and compliance, learn the key factors to ensure safety and functionality in every .

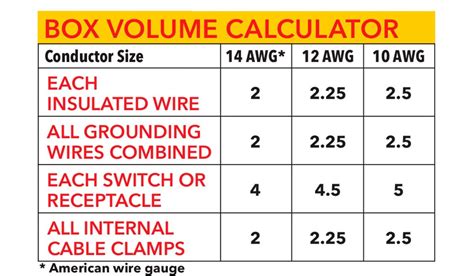

In this DIY guide you will learn how to install a metal back box into a solid wall so that electrical sockets, switches and other objects can be installed. You will also learn about the different sizes of back box and what each should be used for. Unlock the secrets of choosing the perfect back box size for your electrical installations. Dive into our guide to discover standard sizes, factors to consider, and practical tips for safety and functionality.Electrical Boxes vary in size, material, number of gangs, and shape and are designed for specific uses like junctions, outlets, and switch or fixture boxes for wiring in wall or ceiling. Use this guide to determine the best electrical box choice for your application.A typical 4-inch box is the right size, but the actual box dimensions, in particular, box depth and thus the space needed in cubic inches varies depending on how many wires or connectors will be in the box.

Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side. Electrical boxes encase wire connections to protect them from short circuits. They are vital for fire safety and are used for receptacles, ceiling fans, outside outlets, and more. Unless the device is one of the few that contains its own wires, it likely will need an electrical box.

NEC Article 314 covers Outlet, Device, Pull and Junction Boxes; Conduit bodies; Fittings; and Handhole Enclosures. It would go into uses approved and not approved for each particular box. I would suggest you get a NEC Handbook for this Article as it is more descriptive and has additional explanations.There is a huge selection of electrical boxes, varying by size, shape, mounting device, and composition. One of the first distinctions to note is that of new work boxes and remodel or cut-in boxes. These boxes allow you to add new electrical devices without affecting your drywall. Old work boxes are designed to be installed in finished walls, have tabs or clamps that grip the drywall from behind, and are available in both plastic and metal. Explore our in-depth guide on choosing the right back boxes for your electrical installations. From materials and sizes to weatherproofing and compliance, learn the key factors to ensure safety and functionality in every project.

In this DIY guide you will learn how to install a metal back box into a solid wall so that electrical sockets, switches and other objects can be installed. You will also learn about the different sizes of back box and what each should be used for. Unlock the secrets of choosing the perfect back box size for your electrical installations. Dive into our guide to discover standard sizes, factors to consider, and practical tips for safety and functionality.Electrical Boxes vary in size, material, number of gangs, and shape and are designed for specific uses like junctions, outlets, and switch or fixture boxes for wiring in wall or ceiling. Use this guide to determine the best electrical box choice for your application.

A typical 4-inch box is the right size, but the actual box dimensions, in particular, box depth and thus the space needed in cubic inches varies depending on how many wires or connectors will be in the box. Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side. Electrical boxes encase wire connections to protect them from short circuits. They are vital for fire safety and are used for receptacles, ceiling fans, outside outlets, and more. Unless the device is one of the few that contains its own wires, it likely will need an electrical box.

NEC Article 314 covers Outlet, Device, Pull and Junction Boxes; Conduit bodies; Fittings; and Handhole Enclosures. It would go into uses approved and not approved for each particular box. I would suggest you get a NEC Handbook for this Article as it is more descriptive and has additional explanations.There is a huge selection of electrical boxes, varying by size, shape, mounting device, and composition. One of the first distinctions to note is that of new work boxes and remodel or cut-in boxes. These boxes allow you to add new electrical devices without affecting your drywall. Old work boxes are designed to be installed in finished walls, have tabs or clamps that grip the drywall from behind, and are available in both plastic and metal. Explore our in-depth guide on choosing the right back boxes for your electrical installations. From materials and sizes to weatherproofing and compliance, learn the key factors to ensure safety and functionality in every project.

fireplace coal scuttle metal box

standard electrical box size chart

standard electrical box size

standard electrical back box dimensions

This vintage 1999 Looney Tunes Tweety Bird lunch box is a must-have for any collector or fan of the classic cartoon series. With its small size of 7.5 x 5 x 3.5 inches, it's perfect for taking your lunch to work or school.Amazon.com : Tweed Large Capacity A4 Brushed Stainless Steel Postbox Mailbox letterbox Post Box Mail Box Letter Box (Stainless steel) : Tools & Home Improvement

electrical back box dimensions|electrical metal box size chart