cnc machine program setting These commands guide the machine’s every movement, ensuring operations are performed with precision and accuracy. Setting up the CNC program for machining. At its core, CNC programming is about transforming a . Metal fabrication involves cutting, bending, shaping, and assembling metal to create a specific product, while welding involves joining two or more pieces of metal together using heat and pressure.

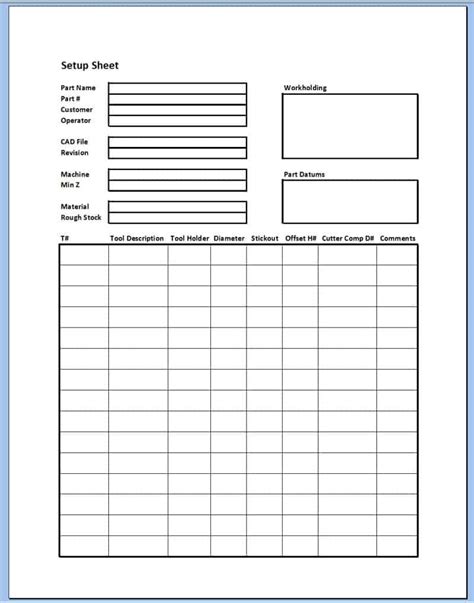

0 · cnc tool set up sheet

1 · cnc machines for dummies

2 · cnc machine setup sheet template

3 · cnc machine setup checklist

4 · cnc machine set up sheet

5 · cnc machine process step by

6 · cnc machine operating instructions

7 · cnc lathe setup sheet

A boxplot, also known as a box plot, box plots, or box-and-whisker plot, is a standardized way of displaying the distribution of a data set based on its five-number summary of data points: the “minimum,” first quartile [Q1], median, third quartile [Q3] and “maximum.”

CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write . CNC programming involves writing a set of commands, known as G-code, that tell the machine how to move and what actions to perform. By programming the CNC machine, operators can automate complex tasks and . Using our chosen programming approach, we will create a g-code part program and update our Setup Sheet to match that part program. Using . These commands guide the machine’s every movement, ensuring operations are performed with precision and accuracy. Setting up the CNC program for machining. At its core, CNC programming is about transforming a .

CNC programming is the process of converting a 3D model into machine-readable instructions in order to perform automated machining operations. Learn more about it here. Computer numerical control (CNC) programming is the process of writing or developing the code that controls the CNC machine to execute the desired machining process. It is the job of a CNC programmer to develop a .CNC (Computer Numerical Control) programming is the backbone of modern manufacturing, allowing machines to perform precise machining operations based on coded instructions. For . Programming a CNC (Computer Numerical Control) machine may seem intimidating, but don’t worry. This guide will take you through each step, making the process clear and straightforward. We will start by understanding .

CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes , and 3D printers. CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write the G-code program, set up the CNC machine with the appropriate tools and workpiece, and run the program while . Parameters tell the CNC every little detail about the specific machine tool being used, and how all CNC features and functions are to be utilized. Nearly every CNC-related issue involves a parameter setting. Parameters specify settings for every CNC feature and function, and there are hundreds, even thousands, for any CNC. CNC programming involves writing a set of commands, known as G-code, that tell the machine how to move and what actions to perform. By programming the CNC machine, operators can automate complex tasks and achieve high levels of precision and accuracy.

Using our chosen programming approach, we will create a g-code part program and update our Setup Sheet to match that part program. Using MeshCAM to create a G-Code Part Program. Drilldown on the link to see how to go about Programming Using CAM Software. Conversational CNC Menu for Milling Operations. These commands guide the machine’s every movement, ensuring operations are performed with precision and accuracy. Setting up the CNC program for machining. At its core, CNC programming is about transforming a design into a set of actionable commands.

CNC programming is the process of converting a 3D model into machine-readable instructions in order to perform automated machining operations. Learn more about it here. Computer numerical control (CNC) programming is the process of writing or developing the code that controls the CNC machine to execute the desired machining process. It is the job of a CNC programmer to develop a program that perfectly replicates the given design. NC, CNC, and DNC are the three types of programmable machining systems.CNC (Computer Numerical Control) programming is the backbone of modern manufacturing, allowing machines to perform precise machining operations based on coded instructions. For beginners entering the field, understanding the basics . Programming a CNC (Computer Numerical Control) machine may seem intimidating, but don’t worry. This guide will take you through each step, making the process clear and straightforward. We will start by understanding the part and then move on to running successful tests.

CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes , and 3D printers. CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write the G-code program, set up the CNC machine with the appropriate tools and workpiece, and run the program while . Parameters tell the CNC every little detail about the specific machine tool being used, and how all CNC features and functions are to be utilized. Nearly every CNC-related issue involves a parameter setting. Parameters specify settings for every CNC feature and function, and there are hundreds, even thousands, for any CNC.

CNC programming involves writing a set of commands, known as G-code, that tell the machine how to move and what actions to perform. By programming the CNC machine, operators can automate complex tasks and achieve high levels of precision and accuracy. Using our chosen programming approach, we will create a g-code part program and update our Setup Sheet to match that part program. Using MeshCAM to create a G-Code Part Program. Drilldown on the link to see how to go about Programming Using CAM Software. Conversational CNC Menu for Milling Operations. These commands guide the machine’s every movement, ensuring operations are performed with precision and accuracy. Setting up the CNC program for machining. At its core, CNC programming is about transforming a design into a set of actionable commands.

CNC programming is the process of converting a 3D model into machine-readable instructions in order to perform automated machining operations. Learn more about it here. Computer numerical control (CNC) programming is the process of writing or developing the code that controls the CNC machine to execute the desired machining process. It is the job of a CNC programmer to develop a program that perfectly replicates the given design. NC, CNC, and DNC are the three types of programmable machining systems.CNC (Computer Numerical Control) programming is the backbone of modern manufacturing, allowing machines to perform precise machining operations based on coded instructions. For beginners entering the field, understanding the basics .

how easy is it to remove a light junction box

cnc tool set up sheet

cnc machines for dummies

cnc machine setup sheet template

Discover the importance of a properly installed and maintained main electrical panel. Essential tips for electrical wiring in your home.

cnc machine program setting|cnc machine process step by