nesting sheet metal parts in solidworks NESTINGWorks 3D design tool to help optimize sheet metal and flat stock designs as well as support the transition from design to manufacturing for sheet metal in the SOLIDWORKS environment. Learn more. NESTINGWorks . For sale is aVintage Military USQMC Metal Storage Box US Military Quarter Master Box Dimensions 16.5 x 14 x 9Markings: USQMC 50 MFD by J. Blickman New York, NY As .

0 · solidworks nesting software download

1 · nesting solutions for solidworks

US Mail Supply designed these USPS approved drop boxes to keep your packages safe, ensuring they get picked up by your postal worker. They feature pry resistant locks and stainless steel hinges for maximum protection.

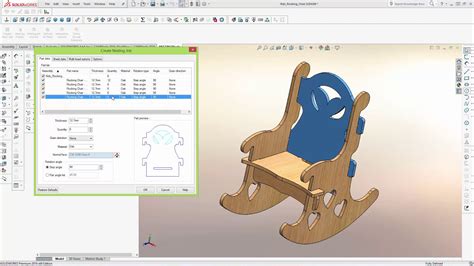

Nest Parts on Sheets, Coils or Small Spaces Inside SolidWorks. Accurate Die Design Software Inc. / Logopress3 (Brookfield, WI) has released Logopress3 NESTING 2018 for SolidWorks that. NESTINGWorks is the newest 3D design tool in the SOLIDWORKS environment to help optimize sheet metal and flat stock designs as well as support the transition.

NESTINGWorks 3D design tool to help optimize sheet metal and flat stock designs as well as support the transition from design to manufacturing for sheet metal in the SOLIDWORKS environment. Learn more. NESTINGWorks .With NESTINGWorks, product designers can efficiently optimize sheetstock layouts — including specifications for grain direction — so they can produce .NESTINGWorks acts within SOLIDWORKS to automatically nests layouts of parts and assemblies for production. With seamless SOLIDWORKS integration, the application can be used to nest flat and 3D part or assembly models made .

To estimate material usage and costs of nested sheet metal parts, you can: Choose the sheet size. Estimate the number of parts that can fit on a sheet. Determine the number of sheets .NESTINGWorks can be used to create efficient layouts of metal, wood or composite based materials, producing the maximum number of parts from a single piece of raw material within . NestingWORKS is a useful add-in that allows us to nest our Sheet Metal SOLIDWORKS Parts and save that to a DXF for cutting. This video will show us how we can use NestingWORKS inside.

Make a reference sketch in the assembly which matches the size of the material stock you are working with. Then start dragging the parts around until they fit best on the .The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. Can we do nesting of sheet metal parts for preparing cutting file to cutting machine. in DWG format Thanks Raj . Can we do nesting of sheet metal parts for preparing cutting file to cutting machine. in DWG format. Thanks. Raj. answers: 2. View or Reply . Use .The Bounding Box Nesting Preview displays the alignment drawing of the nested elements. The red dotted line is the sheet metal offset and the black dotted line is the bounding box offset.

This video shows how to do industrial nesting of sheetmetal parts designed in solidworks, NX quickly using genetic algorithm based software deepnest and expo.

solidworks nesting software download

In sheet metal forming, wipe bending process plays a major role in which the sheet metal tries to return to its original shape after release of the load by a punch, due to the elastic stresses.This new 3D nesting application is seamlessly integrated within SOLIDWORKS, enabling automated nesting of flat or 3D part or assembly models made from sheet stock. NESTINGWorks automatically nests layouts of SOLIDWORKS parts and assemblies for production. . well as support the transition from design to manufacturing for sheet metal in the .•NESTING Works, developed by Geometric Americas, Inc., is an automatic, true-shape nesting program that easily creates fast and efficient nested layouts. It is seamlessly integrated within SOLIDWORKS® and allows nesting of flat or 3D solid or sheet metal parts and . In automatic nesting, the CAD software uses algorithms to arrange the design in the most possible way, based on the shapes, sizes and number of parts, compared to the material sheet’s dimensions. Nesting is an extremely complicated problem in applied mathematics. A Boss laser machine cutting the nested design shown in the preceding image.

2. Our second application would ideally import, flatten, and nest solidworks sheet metal parts, create reports with sheet layouts, and post process to NC - A nice CAM package, like Lantek or Sigmanest/Solidnest. OR (less than ideal) import DXF's, true nest, export full sheet dxf's for other CAM software to process. We're a basic steel fab shop.Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .

the distance of parts:2 mm; the distance from the edge is 2 mm; part quantity is 3 pieces like below. Which software can calculate the minimum size of nesting sheet metal? It means give me the size like 100mmX1200mm. I have tried Geometric NESTINGWorks but it doesn't have this function.

This new 3D nesting application is seamlessly integrated within SOLIDWORKS, enabling automated nesting of flat or 3D part or assembly models made from sheet stock. NESTINGWorks automatically nests layouts of SOLIDWORKS parts and assemblies for production. . well as support the transition from design to manufacturing for sheet metal in the .The Bounding Box Nesting Preview displays the alignment drawing of the nested elements. The red dotted line is the sheet metal offset and the black dotted line is the bounding box offset.This new 3D nesting application is seamlessly integrated within SOLIDWORKS, enabling automated nesting of flat or 3D part or assembly models made from sheet stock. NESTINGWorks automatically nests layouts of SOLIDWORKS parts and assemblies for production. . well as support the transition from design to manufacturing for sheet metal in the .Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .

seamlessly integrated within SOLIDWORKS® and allows nesting of flat or 3D solid or sheet metal parts and assemblies. NESTINGWorks can be used to create efficient layouts of metal, wood or composite based materials, producing the maximum number of parts from a single piece of raw material within minutes. Getting Help/TroubleshootingAs a test, try to insert an axis on the conical face. If you can insert an axis, the model is an exact cone. If you cannot insert an axis, then the model is not an exact cone and cannot be unfolded. However, sheet metal parts created with the Lofted Bends .This new 3D nesting application is seamlessly integrated within SOLIDWORKS, enabling automated nesting of flat or 3D part or assembly models made from sheet stock. NESTINGWorks automatically nests layouts of SOLIDWORKS parts and assemblies for production. . well as support the transition from design to manufacturing for sheet metal in the .To estimate material usage and costs of nested sheet metal parts, you can: Choose the sheet size; Estimate the number of parts that can fit on a sheet; Determine the number of sheets necessary; You can also preview the nested parts with or without offsets along the X and Y dimensions. Previously, you had to select materials that were estimated .

This new 3D nesting application is seamlessly integrated within SOLIDWORKS, enabling automated nesting of flat or 3D part or assembly models made from sheet stock. NESTINGWorks automatically nests layouts of SOLIDWORKS parts and assemblies for production. . well as support the transition from design to manufacturing for sheet metal in the .Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

This new 3D nesting application is seamlessly integrated within SOLIDWORKS, enabling automated nesting of flat or 3D part or assembly models made from sheet stock. NESTINGWorks automatically nests layouts of SOLIDWORKS parts and assemblies for production. . well as support the transition from design to manufacturing for sheet metal in the .Material Weight. Calculates the weight of the part based on the values defined for Material, Thickness from template, and Area to cost. Sheet Size. Calculates the material cost of a part by determining the number of parts that can be manufactured from the selected sheet.With seamless SOLIDWORKS integration, the application can be used to nest flat and 3D part or assembly models made from sheet stock, like sheet metal, plastics, plates, composites or wood. NESTINGWorks is an intuitive and simple application with the power to optimize not only your design, but to also maximize the number of parts that can be .Search 'Creating Custom Operations for Sheet Metal Parts' in the SOLIDWORKS Knowledge Base. Provide feedback on this topic. SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to our documentation team.

Automatic Part Sorting – SS-Nest automatically sorts parts based on material type, material thickness, and assigned CNC machine. Automatic Sheet Selection – Automatically selects the optimum sheet size or sizes to minimize material scrap. Part In Part Nesting – Nests parts inside of larger cutouts improving material utilization.Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

nesting solutions for solidworks

$9.99

nesting sheet metal parts in solidworks|nesting solutions for solidworks